Superlarge-diameter rotation body tool fixture

A technology of ultra-large diameter and tooling fixtures, applied in the field of tooling fixtures, can solve the problems of uncontrollable deformation, unguaranteed precision, and low production efficiency, and achieve the effects of reduced clamping stability, more processing points, and difficult hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

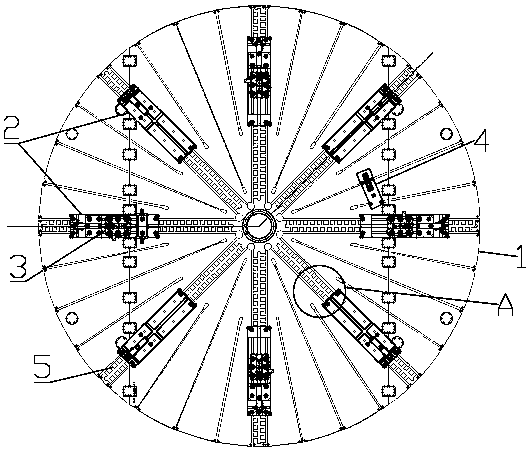

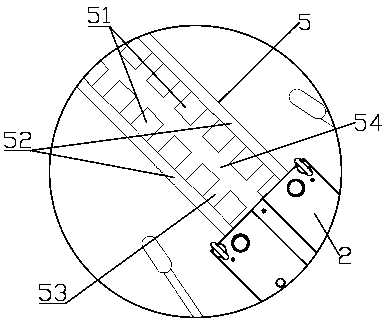

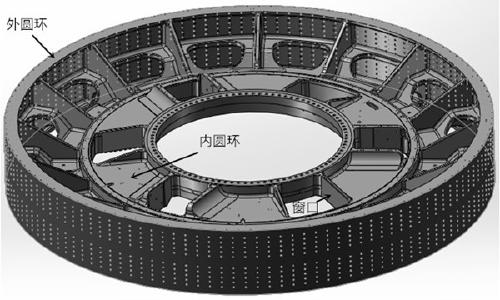

[0032] To provide a tooling fixture for a super-large diameter rotary body, see Figure 1-5 , the super-large-diameter revolving body is a wind power stator and rotor (6), its length is 6.9m, the width of the outer ring is 1.2m, and the gross weight is 40t; the fixture includes a rotary table (1) and 8 supports (2) , also includes 4 clamps, the clamps are arranged on the support (2) at intervals; the upper surface of the rotary table is provided with 8 rails (5) radially from its rotation center; each of the The track (5) has two rows of locking teeth (51), two slideways (52) located outside the two rows of locking teeth (51), and a guide groove (54) between the two rows of locking teeth (51). ); two adjacent teeth (51) in the same row are separated by a slot (53); the support (2) can slide on the track (5) along the slideway (52); The support (2) is used to support the outer ring of the super-large-diameter revolving body; the clamp is used to clamp the outer wall of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com