On-orbit inspection linear motion mechanism and on-orbit inspection device

A technology of linear motion and driving mechanism, applied in transportation and packaging, measuring devices, motor vehicles, etc., can solve the problems of reduced sealing performance, structural deformation, temperature rise, etc., and achieve the effect of ensuring sustainable driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

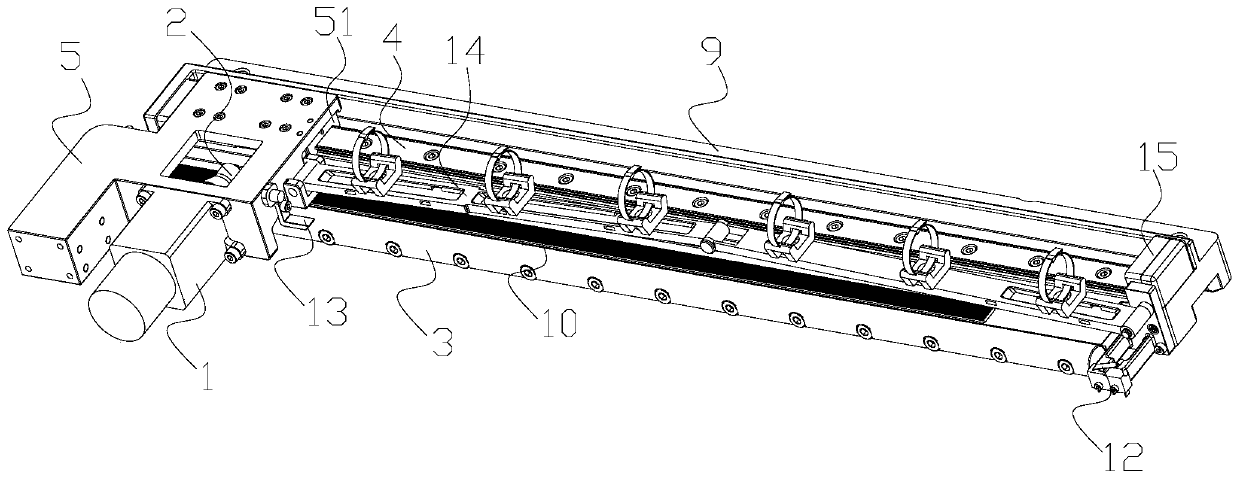

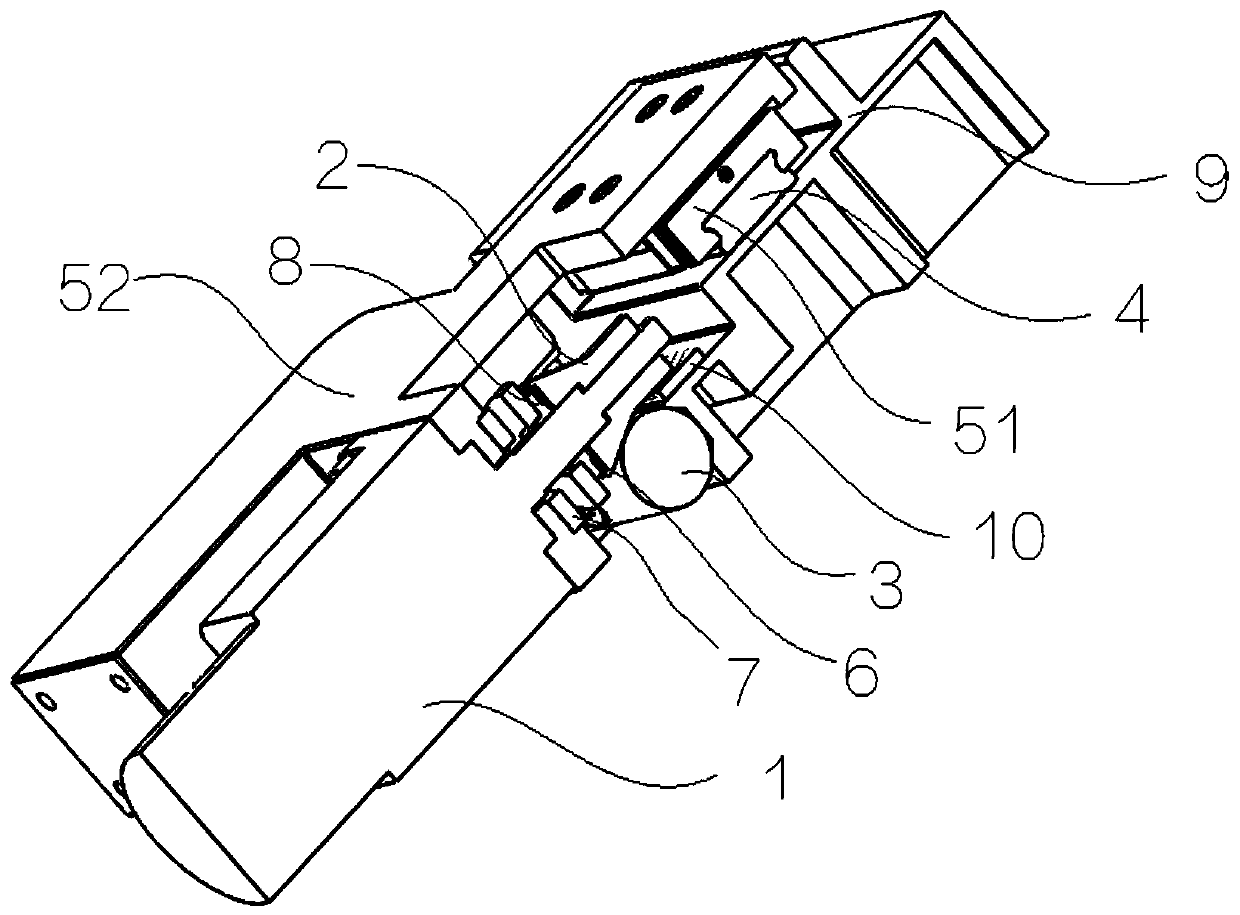

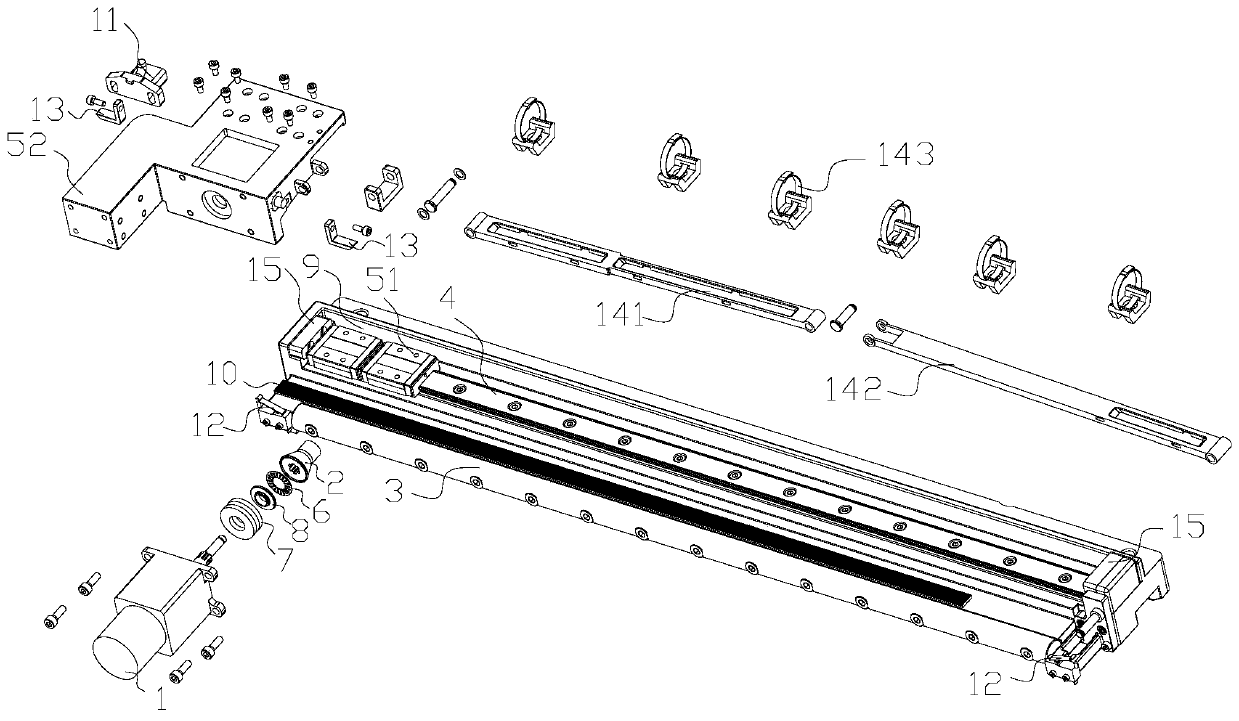

[0080] Such as Figure 1-6 As shown, an on-orbit inspection linear motion mechanism includes:

[0081] drive mechanism 1,

[0082] The conical friction wheel 2 is splined to the output shaft of the drive mechanism 1, and the spline section of the conical friction wheel 2 is larger than the spline section of the output shaft of the drive mechanism 1;

[0083] The friction rod 3 is frictionally matched with the conical friction wheel 2; the conical outer peripheral side of the conical friction wheel 2 abuts on the friction rod 3;

[0084] The guide rail 4 is arranged in parallel with the friction bar 3;

[0085] A slider assembly 5, one end of the slider assembly 5 is slidably mounted on the guide rail 4, and the other end is fixedly connected with the casing of the drive mechanism 1;

[0086] The spring 6 is sheathed on the output shaft of the driving mechanism 1, and sandwiched between the big end of the conical friction wheel 2 and the other end of the slider assembly 5; t...

Embodiment 2

[0118] An on-orbit inspection device for material exposure optical space, including an inspection mechanism and an on-orbit inspection linear motion mechanism as described above, the on-rail inspection linear motion mechanism and the inspection mechanism are parallel to the exposed surface of the material to be inspected , the inspection mechanism is fixedly connected with the slider assembly 5 , an optical imaging module is slidably installed on the inspection mechanism, and the sliding direction of the optical imaging module is perpendicular to the guide rail 4 .

[0119] Specifically, in some embodiments, the inspection mechanism has the same structure as the above-mentioned on-rail inspection linear motion mechanism. The slider plate 52 is fixedly connected, and an optical imaging module is fixedly installed on the slider plate 52 of the inspection mechanism. The optical imaging system moves horizontally and linearly, and the optical imaging module slides on the inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com