Packaging barrel automatic buckle device

A technology of automatic buckle and packaging barrels, which is applied in the directions of packaging, transportation packaging, transportation and packaging to achieve the effect of stable and efficient operation of the equipment and guarantee of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The automatic clamping device for packaging barrels according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

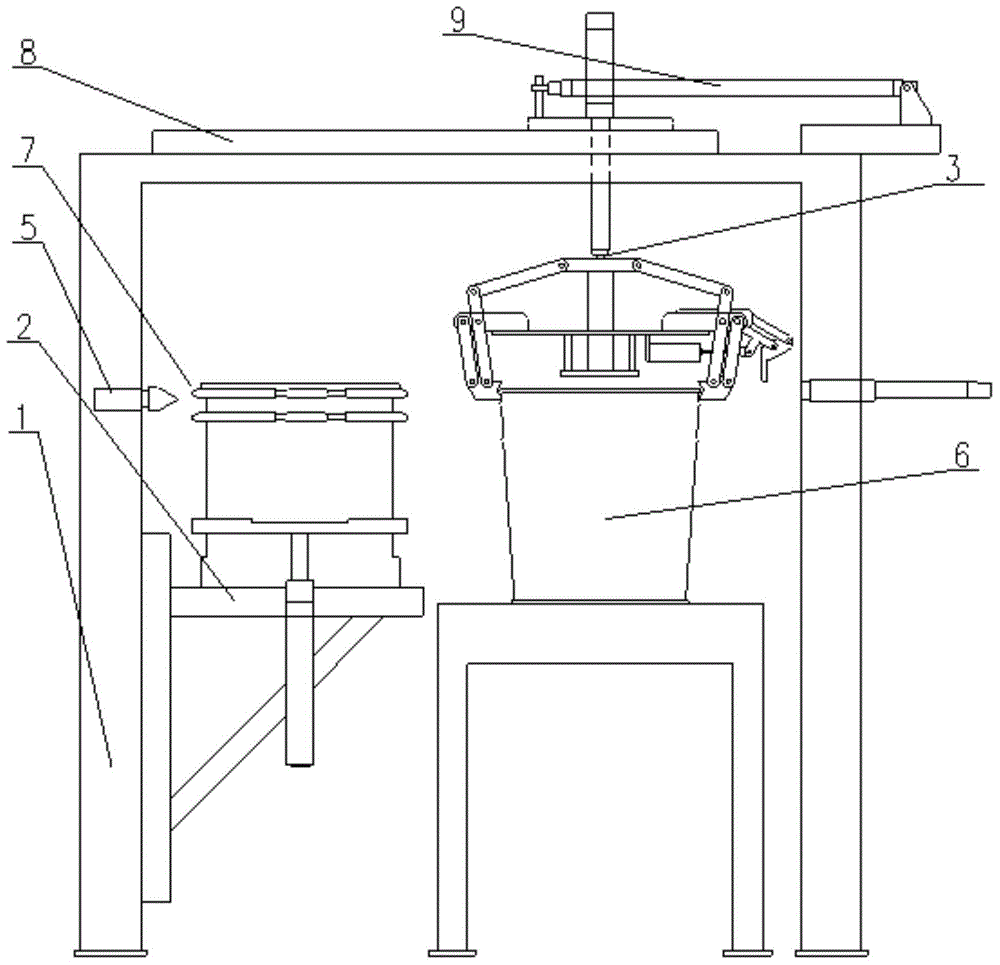

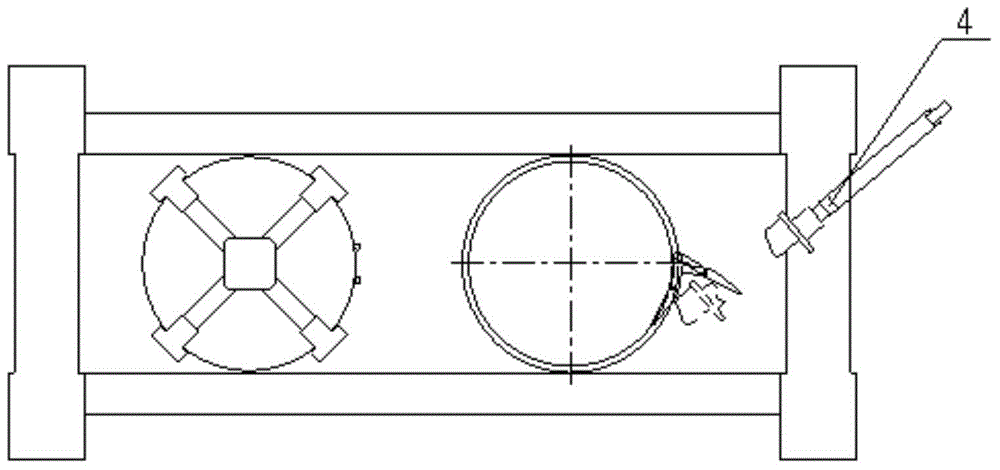

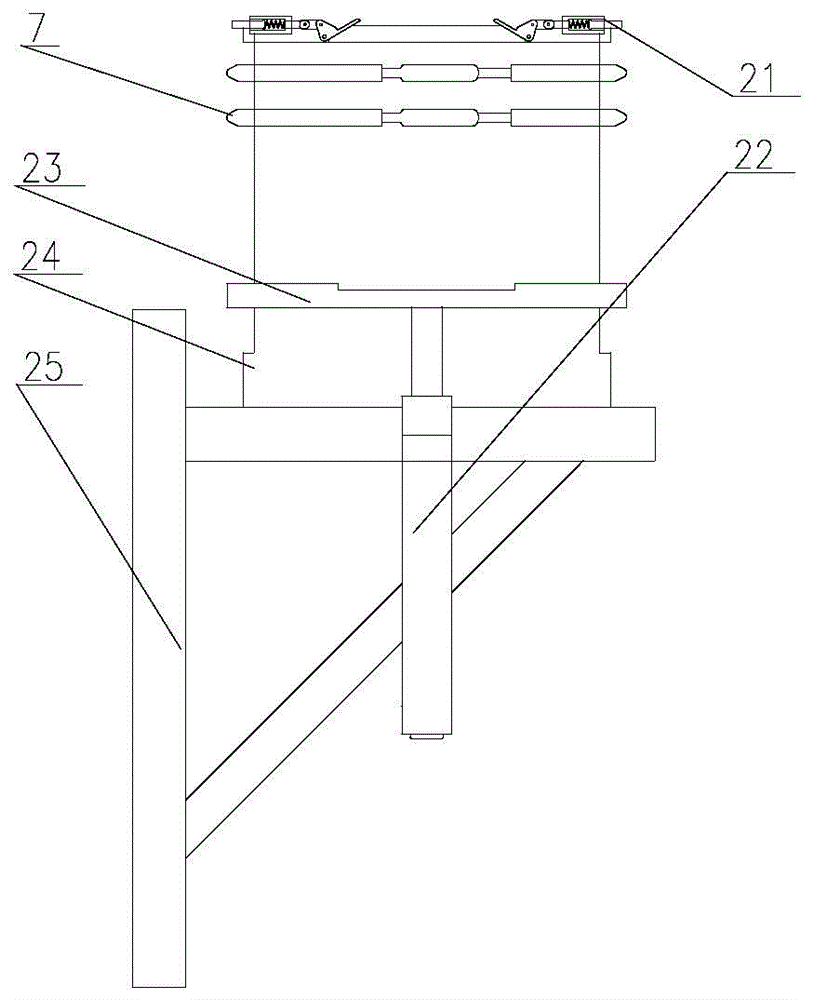

[0021] Such as figure 1 and figure 2 As shown, the main working objective of the automatic buckling device of the present invention is to put the barrel hoop 7 on the material barrel 6 and fasten and seal it. It mainly includes a frame 1, a barrel hoop storehouse 2, and a barrel hoop clamping device 3. It is composed of barrel hoop locking device 4, hoop limit device 5 and other mechanisms.

[0022] Bucket hoop warehouse 2 is fixed on the lower left of frame 1 by bolts, guide rail 8 is fixed on the top of frame 1, barrel hoop clamping device 3 is fixed on guide rail 8, cylinder 9 drives bucket hoop clamping device 3 on guide rail 8 Sliding, the left limit position of the cylinder 9 is the hoop removal station, and the right limit position is the buckle hoop station; the hoop li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com