Food packaging bag storing and transferring device

A transfer device and packaging bag technology, which is applied in the field of packaging and bag making, can solve the problems of reducing production efficiency, scattered packaging bags, and increasing the workload of operators, and achieves the effect of improving orderliness and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

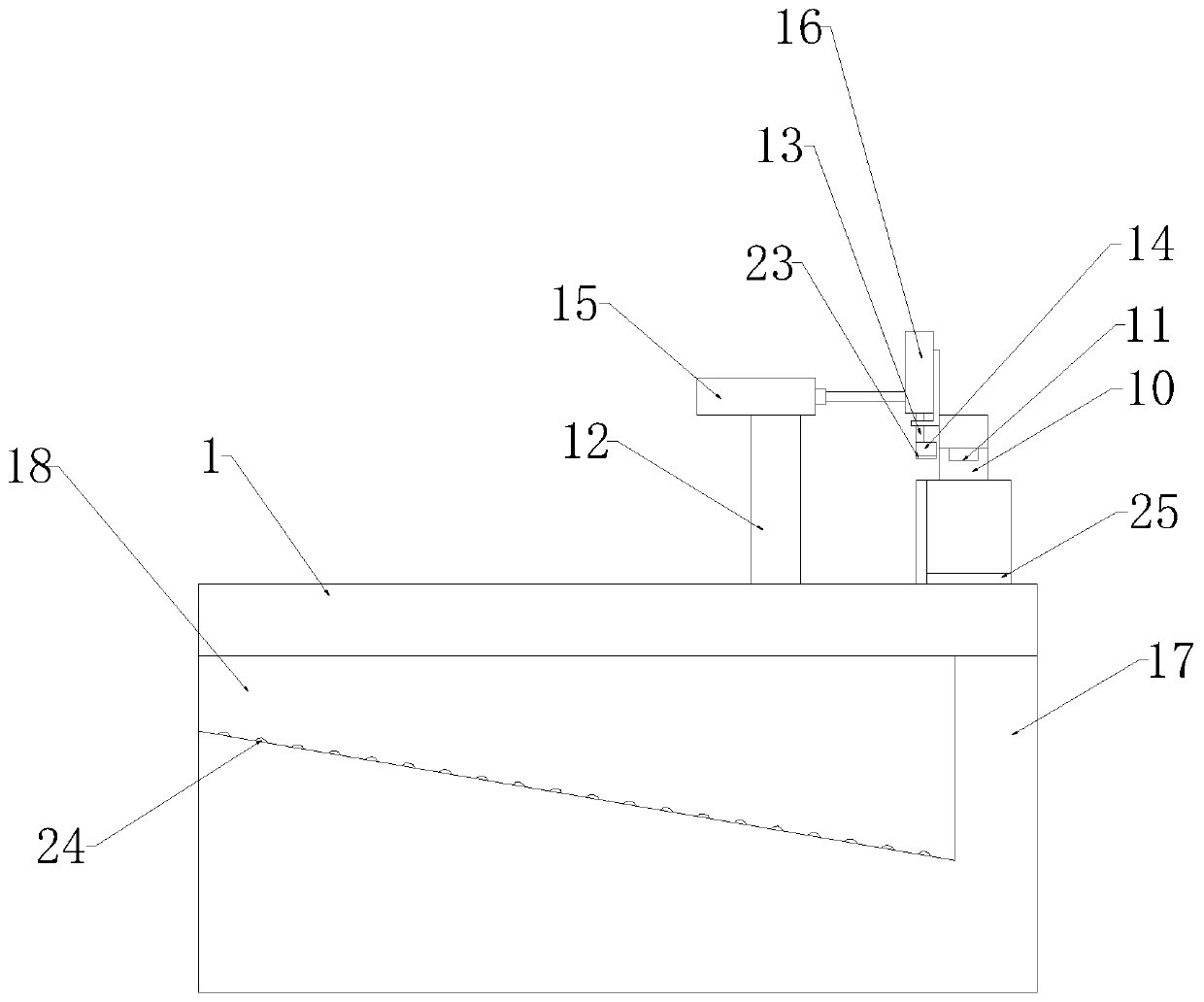

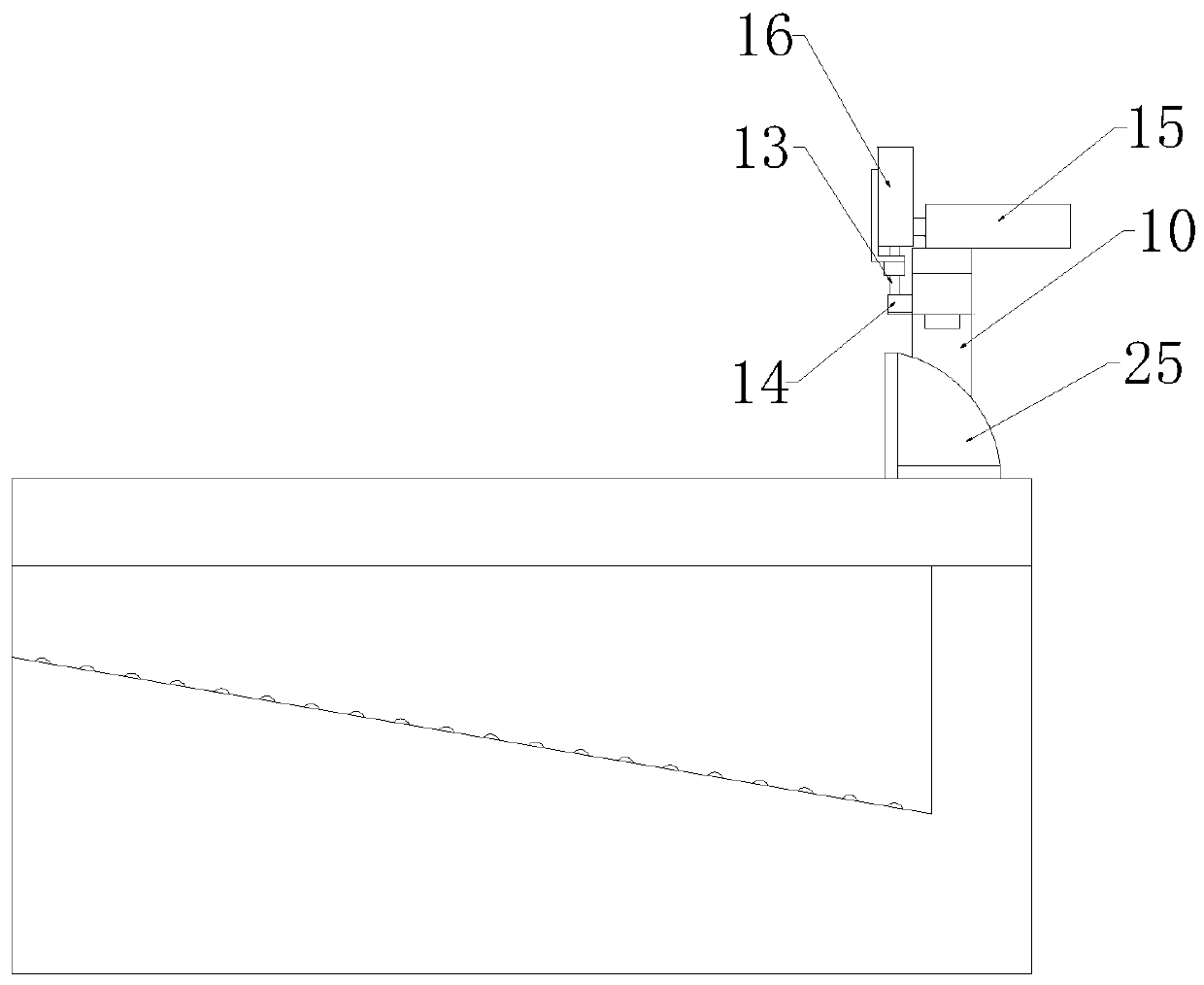

[0057] Such as Figure 1 to Figure 9 As shown, the food packaging bag storage transfer device includes a transmission frame 1 and several turnover boxes;

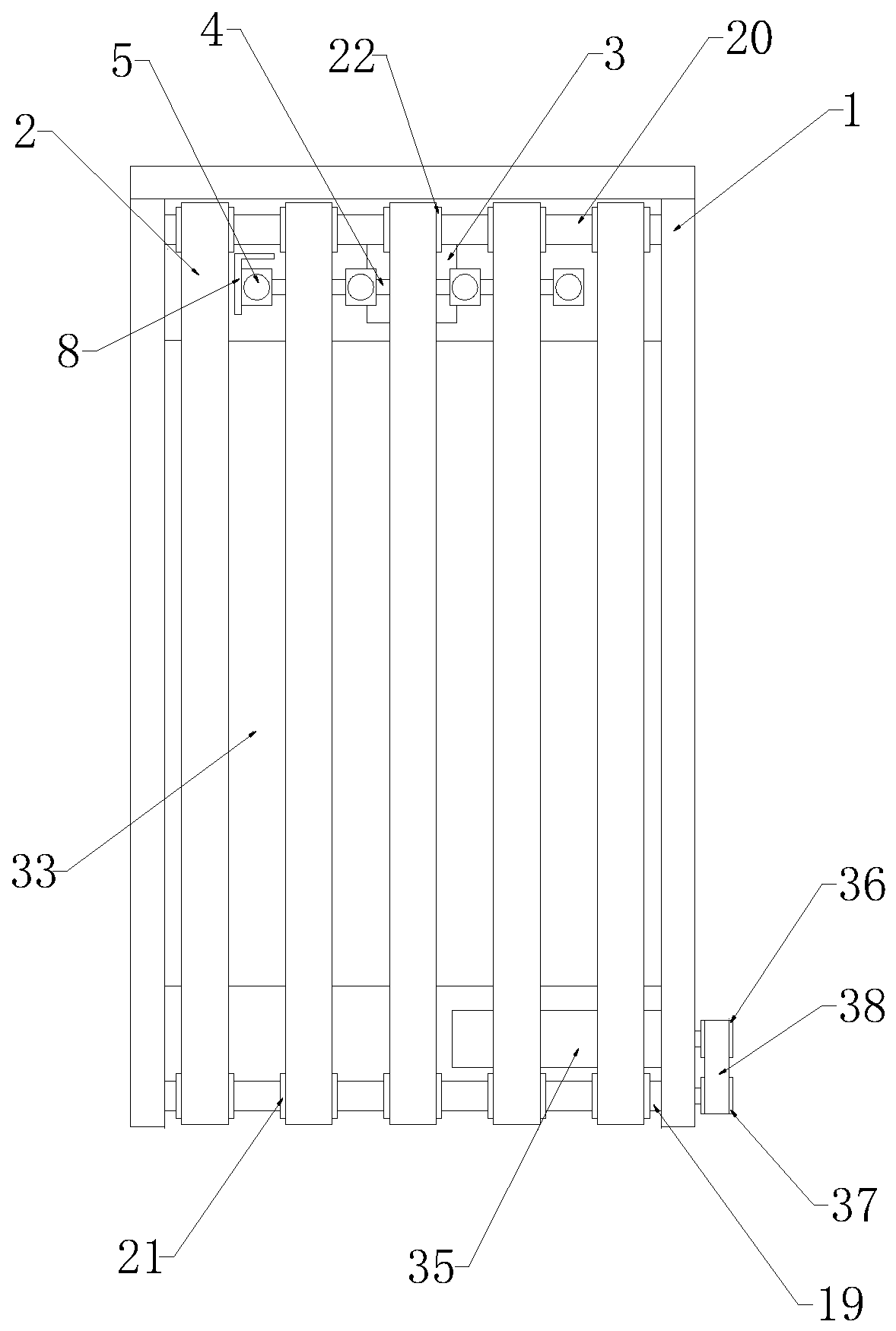

[0058] The transmission frame 1 is provided with several transmission belts 2 arranged at intervals, and the transmission frame 1 is also equipped with a belt drive assembly for driving the transmission belt 2;

[0059] A jacking drive device 3 is installed on the transmission frame 1, and the output end of the jacking drive device 3 is connected with a jacking positioning frame 4, and the jacking positioning frame 4 has several jacking positioning rods 5 arranged in a staggered manner with the conveyor belt 2. The lifting drive device 3 acts on the lifting positioning frame 4, so that: the lifting positioning rod 5 can move up and down relative to the transmission frame 1;

[0060] The jacking positioning bar 5 is also connected with a positioning suction nozzle 7 positioned at the side of the jacking positioning bar 5 th...

Embodiment 2

[0065] In this embodiment, the following further limitations are made on the basis of Embodiment 1: the bottom end of the box body 1 is provided with a positioning groove 29 that can fit into the top end of the jacking positioning rod 5 .

[0066] The top surface of the jacking positioning rod 5 should have enough area so that it can cooperate with the positioning groove 29 to locate the turnover box.

[0067] Preferably, the outer surface of the jacking and positioning rod 5 located at the end among the several jacking and positioning rods 5 is also connected to the limiting frame 8 .

[0068] In this embodiment, the limit frame 8 can be set in an L shape, with the conveying direction of the conveyor belt as the front, the limit frame 8 can limit the rear and side of the turnover box.

Embodiment 3

[0070] In this embodiment, the following further limitations are made on the basis of Embodiment 1: the top end of the jacking positioning rod 5 is connected with an anti-slip layer 9 .

[0071] The anti-slip layer 9 can be made of rubber or silica gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com