Metal color archaized brick and production method thereof

A technology of metal color and antique bricks, applied in the field of ceramic construction, to achieve good anti-skid, excellent physical properties, and enhance the effect of vividness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

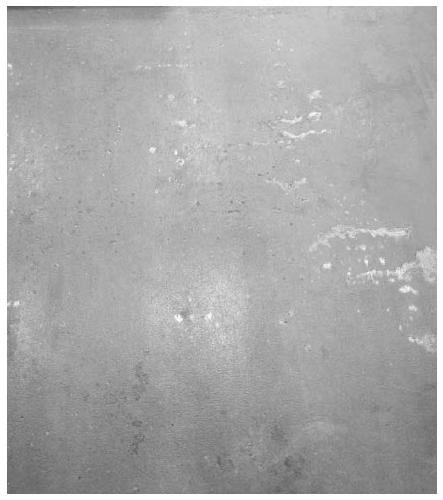

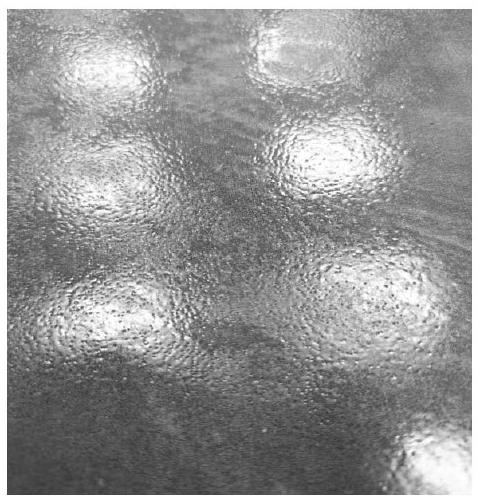

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing an antique tile with metallic color, comprising the following steps: firstly, ink-jet printing a colored ink on the surface of a green body, and then ink-jet printing a color-developing flux to improve the vividness and gloss of the color; finally, burning It is an antique brick with metal-like color and metal-like texture. Preferably, the pattern grayscale of the ink-jet printing chromogenic flux is 20%-120%. When the grayscale of the color-developing flux is lower than 20%, the surface gloss is not greatly improved, and the surface gloss enhancement effect and layering effect are not obvious; when the grayscale of the color-developing flux is higher than 120%, the color-developing flux The fluxing effect reduces the firing temperature of the covering glaze at the corresponding position, and it is easy to cause the covering glaze at the corresponding position to overfire and bubble.

[0024] Metal materials will undergo va...

Embodiment 1

[0054] 1. Prepare the whole billet. Weigh each raw material according to the raw material ratio of the whole billet for raw material collection, crush, forklift batching, put into a ball mill for wet ball milling, and sieve with 250 meshes to remove iron to obtain mud material. The specific gravity of mud is 1.72. The mud flow rate is 56s, and the ball milling fineness can be 3.1%. The green body powder can be obtained by spraying the mud material into powder and aging it. The moisture range of the green body powder is controlled at 7.7%. The particle gradation of the green body powder is as follows: below 30 mesh: less than 15%, 30 mesh to 60 mesh greater than 75%, 60 mesh to 80 mesh less than 10%.

[0055] 2. Drying the body to obtain a dry body.

[0056] 3. Prepare the bottom glaze according to the composition requirements of the bottom glaze. The chemical composition of the bottom glaze formula is: Il 3.51%; SiO 2 56.18%; Al 2 o 3 25.09%; CaO 0.27%; MgO 0.22%; K ...

Embodiment 2

[0070] Basically the same as Example 1, the difference is: the chemical composition of the covering glaze is: IL8.5%; SiO 2 44.10%; Al 2 o 3 19.00%; CaO 3.59%; BaO 9.16%; MgO 2.98%; 2 O 3.54%; ZnO 3.10%; Na 2 O 2.40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com