Automatic water proportioning device

An automatic technology for measuring water, applied in the field of winemaking, can solve the problems of uneven water splashing and high labor intensity, and achieve the effect of satisfying the moisture content of entering the cellar, reducing labor intensity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

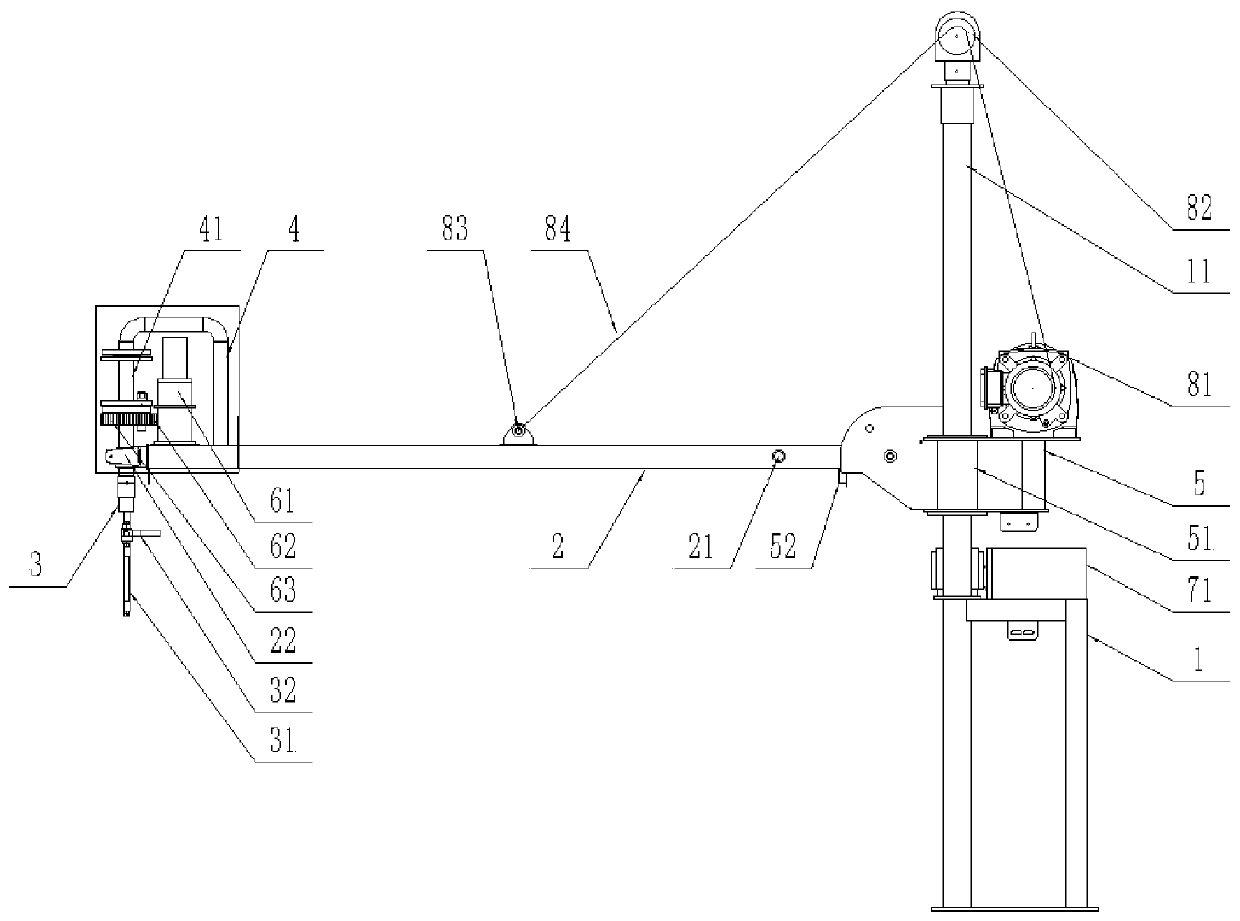

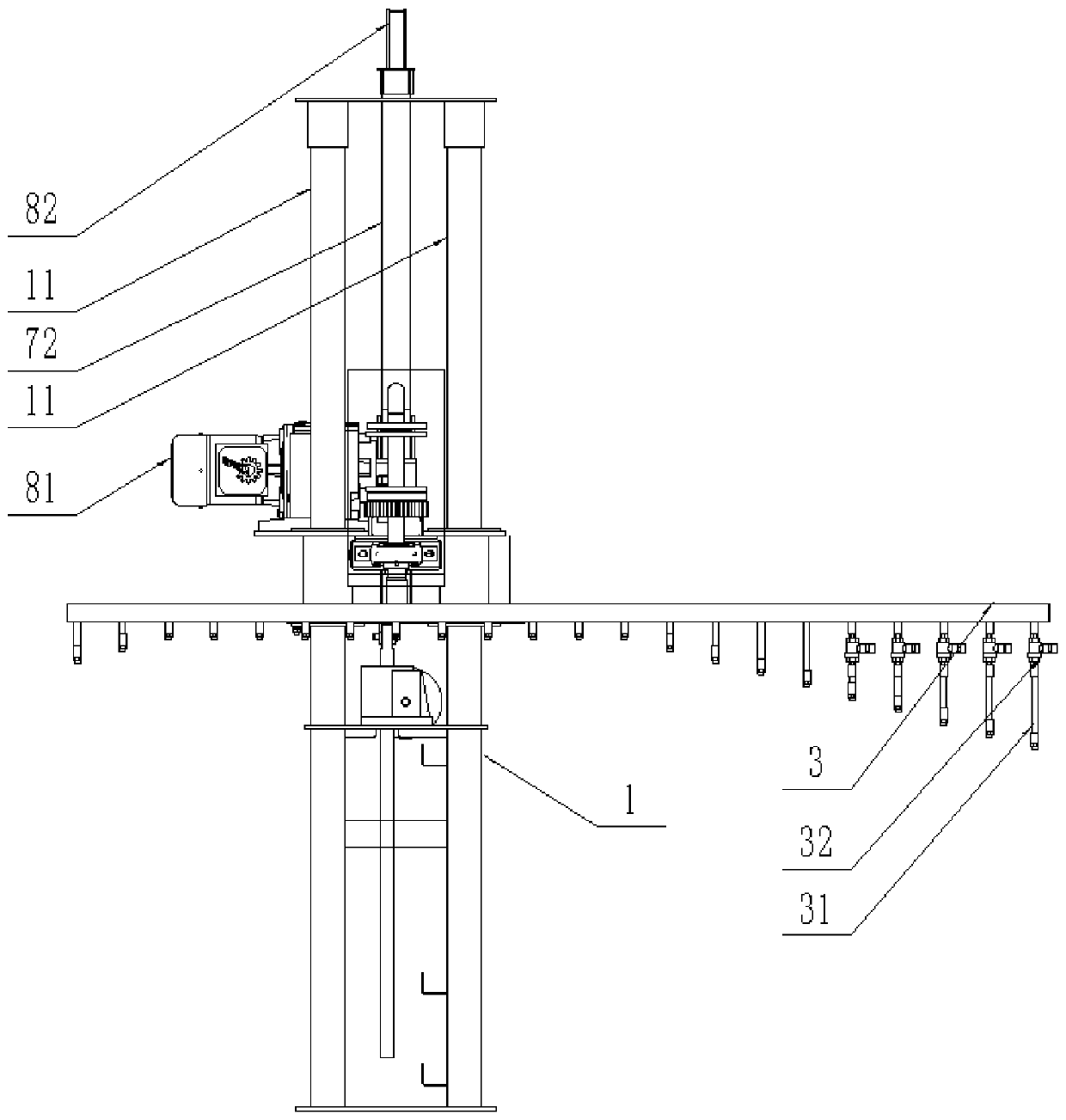

[0034] like Figure 1 ~ Figure 4 As shown, the automatic measuring water device of the present invention includes: a frame 1; Closed; the water spray pipe 3 is horizontally arranged below the end of the cantilever 2 away from the frame 1, and communicates with the cantilever 2 through the connecting pipe 4. A rotary joint 41 is arranged on the connecting pipe 4, and vertical The downward spray head 31 ; the power mechanism, arranged on the cantilever 2 , is used to drive the water spray pipe 3 to rotate in the horizontal direction relative to the cantilever 2 . The power mechanism includes a DC motor reducer 61 , a first gear 62 and a second gear 63 arranged on the boom 2 and connected in sequence. The second gear 63 is arranged on the connecting pipe 4 below the rotary joint 41 . The length of the spray head 31 gradually increases from the junction of the water spray pipe 3 and the connecting pipe 4 to both sides of the water spray pipe 3 . The spray head 31 is provided wit...

Embodiment 2

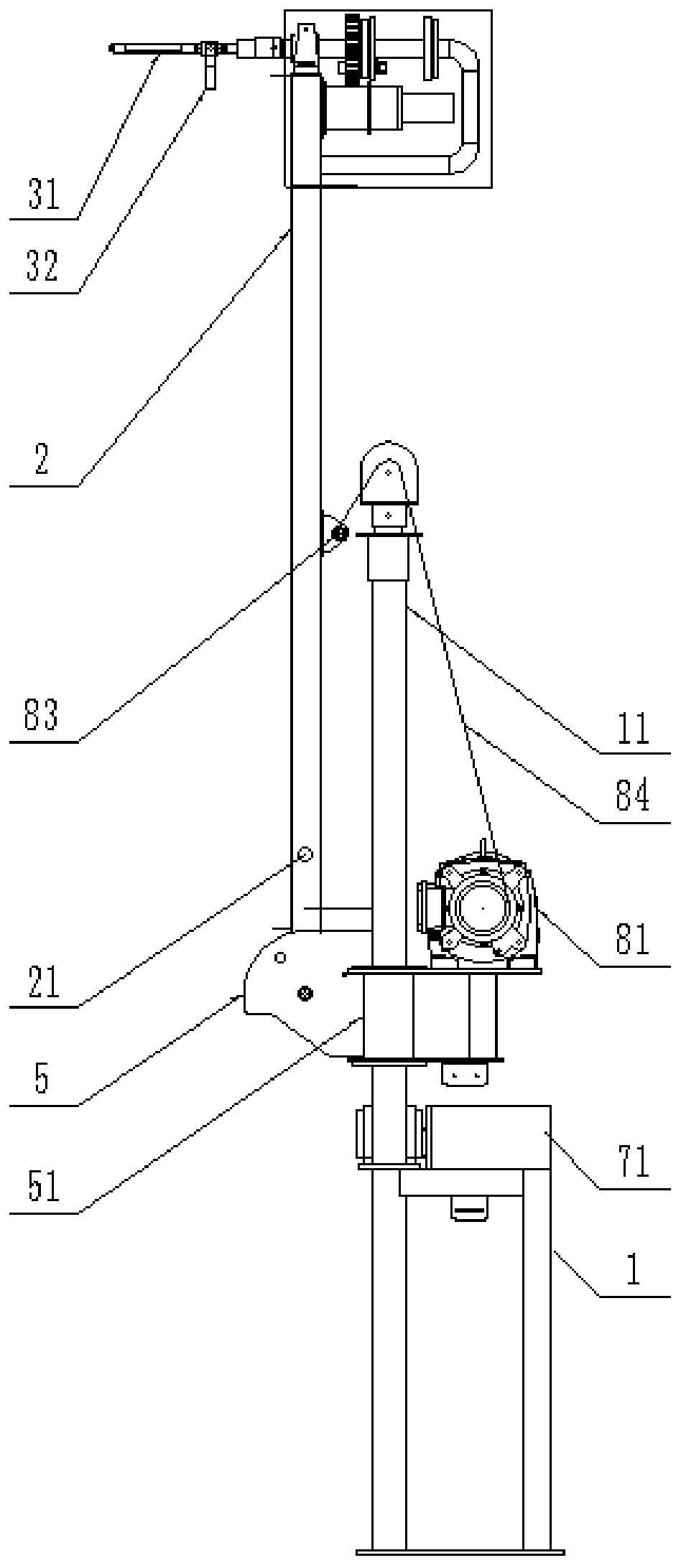

[0037] like Figure 1 ~ Figure 4 As shown, this embodiment is a further improvement made on the basis of Embodiment 1. The frame 1 is provided with a lifting support 5 that is movably connected with the frame 1, and the cantilever 2 is connected with the frame 1 through the lifting support 5; Up and down in a straight direction. The lifting mechanism is a screw lift, which includes a lift 71 arranged on the frame 1 and a screw 72 connected to the lift 71 and vertically arranged, and the lifting support 5 is provided with a screw thread matched with the screw 72 Set of 51. The frame 1 is provided with a guide shaft 11 parallel to the screw rod 72 .

[0038] Working principle: pour the steamed fermented grains on the ground below the water spray pipe 3, and adjust the distance from the spray head 31 to the surface of the fermented grains through the lifting mechanism according to the actual stacked size of the fermented grains. The lifting mechanism can drive the lifting suppo...

Embodiment 3

[0040] Such as Figure 1 ~ Figure 4 As shown, this embodiment is a further improvement made on the basis of Embodiment 1. The cantilever 2 is hinged to the lifting support 5; it also includes a rotating mechanism for driving the cantilever 2 to rotate around the lifting support 5 in the vertical direction. The rotating mechanism comprises a winch 81 arranged on the lifting support 5, a fixed pulley 82 above the winch 81, a pin shaft 83 arranged on the cantilever 2, and a steel wire rope 84. One end of the steel rope 84 is connected with the winch 81, and the other end is connected with the winch 82 by the fixed pulley 82. Pin shaft 83 is connected.

[0041] Working principle: After spraying the measured water, the operator needs to mix the fermented grains and then shovel the fermented grains onto the cooling bed. Therefore, the cantilever is rotated around the frame to the top of the frame through the rotating mechanism to make room for the operator to operate and avoid The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com