Rhythm slub yarn and production method thereof

A slub yarn and rhythm technology, applied in the field of spinning, can solve the problem of no yarn with rhythm and rhythm, and achieve the effect of breaking through the production mode, rich layers and unique style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

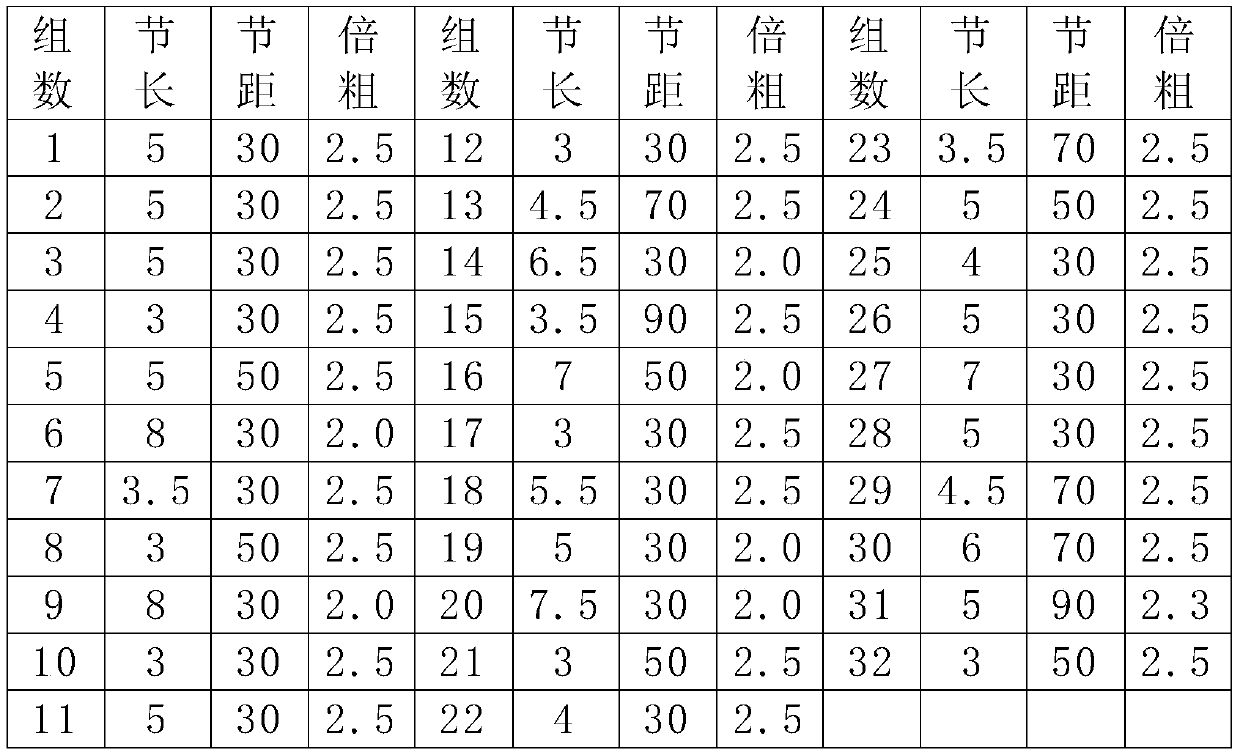

[0032] Rhythm and rhythm slub yarn specification of the present invention is combed 60 lbs yarn varieties, and cotton is 100% Xinjiang fine cotton; The pitch and thicker parameters are designed as follows:

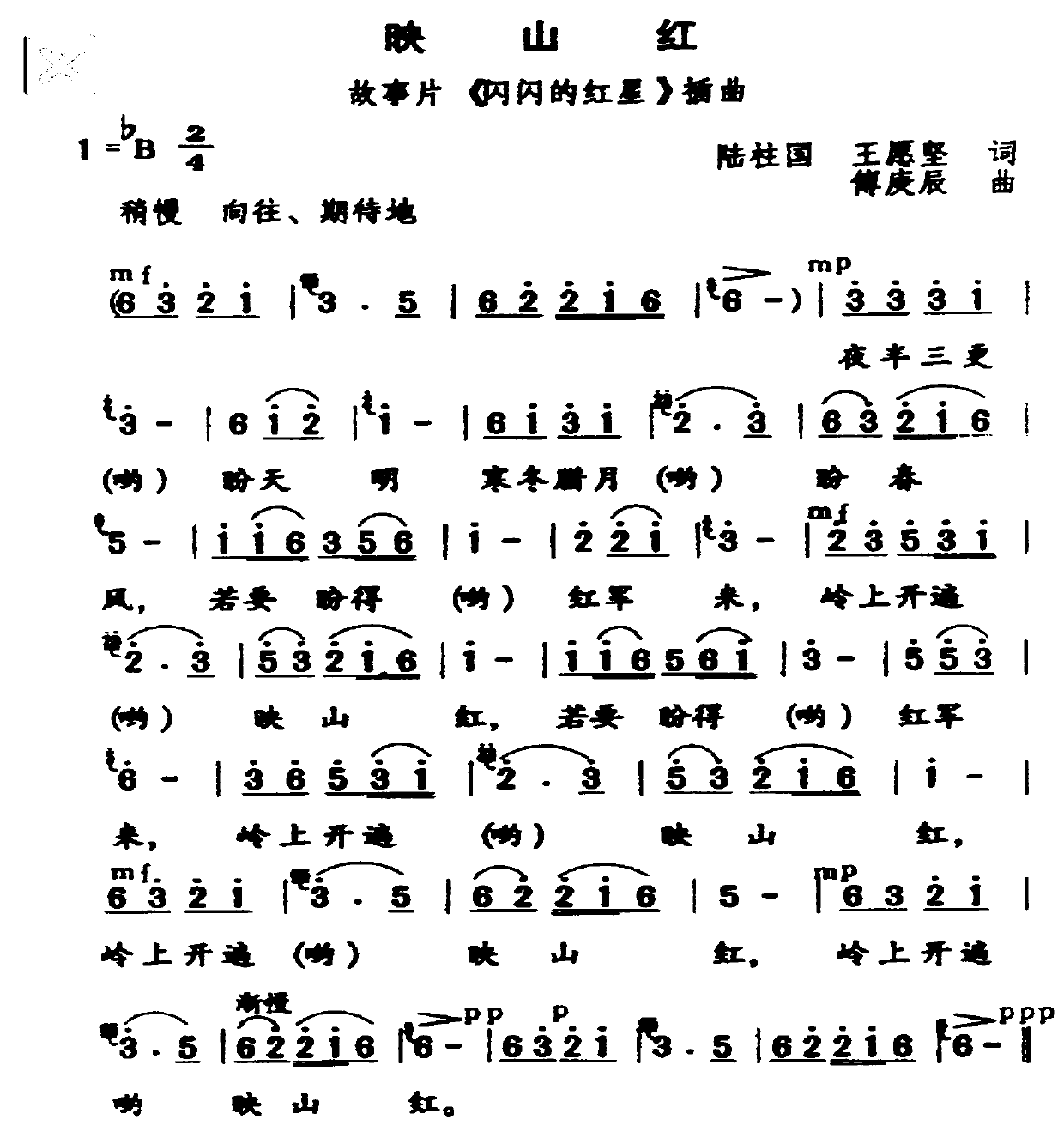

[0033] An excerpt from the music score of the reference piece "Azalea" (see figure 1 ).

[0034] 7 notes represent the length of the bamboo joint:

[0035] 1=section length 3cm; 2=section length 4cm; 3=section length 5cm; 4=section length 6cm; 5=section length 7cm; 6=section length 8cm; 7=section length 9cm; Note values are averaged.

[0036] The note spacing represents the bamboo pitch:

[0037] Benchmark distance=pitch 30cm; short distance=pitch 10cm; long distance=pitch 50cm; distance across two notes=pitch 70cm; distance across 3 notes=pitch 90cm.

[0038] The high and low pitches represent thicker bamboo joints:

[0039] Base pitch = 2.0 times thicker; low pitch = 1.5 times thicker; high pitch = 2.5 times thicker, one base tone and one high pitch = 2.3 times t...

Embodiment 2

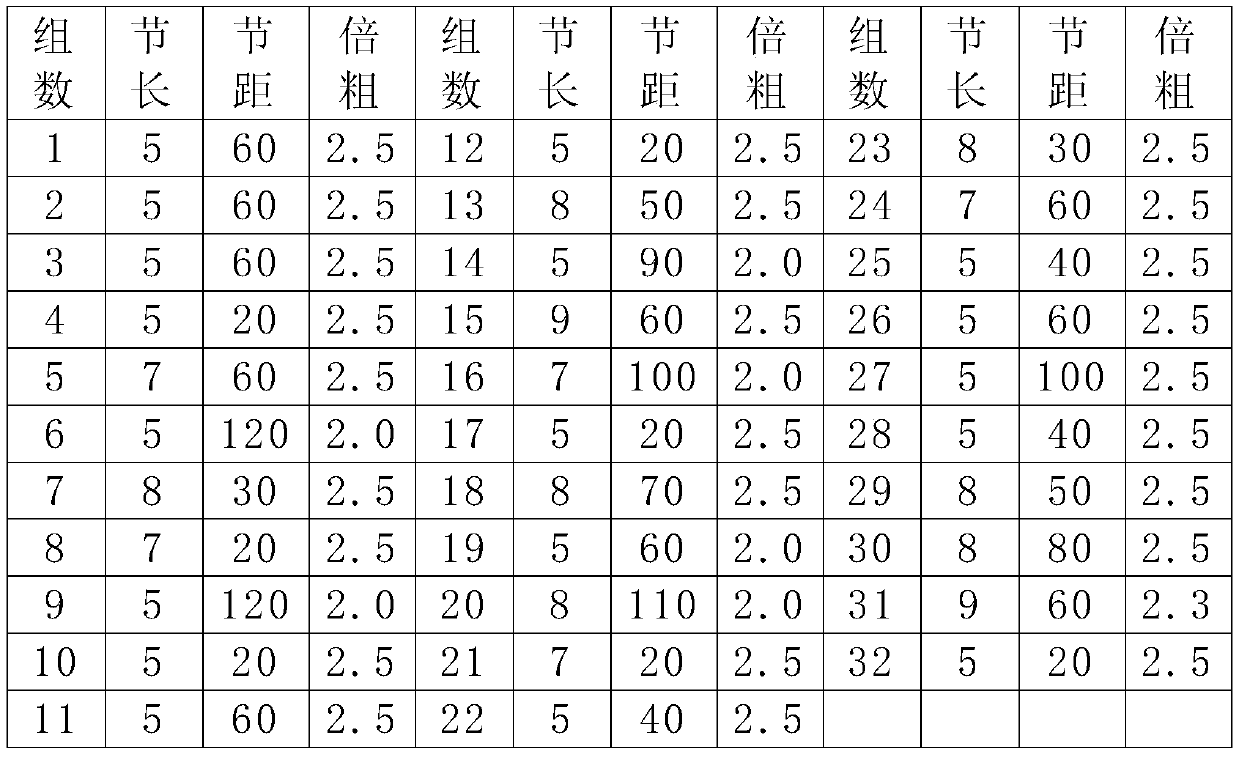

[0055] The specification of the rhythmic yarn of the present invention is a combed 40-count yarn variety, and the cotton blend is 100% Xinjiang fine-staple cotton.

[0056] The parameters of note, note pitch, pitch change and slub yarn node length, pitch, and double thickness of the music score are designed as follows:

[0057] An excerpt from the music score of the reference piece "Azalea" (see figure 1 ).

[0058] 7 notes represent bamboo pitch:

[0059] 1=pitch 20cm; 2=pitch 40cm; 3=pitch 60cm; 4=pitch 80cm; 5=pitch 100cm; 6=pitch 120cm; 7=pitch 140cm; value average;

[0060] The note spacing represents the length of the slub:

[0061] Benchmark distance = section length 5cm; short tone interval = section length 3cm; long tone interval = section length 7cm; span of two notes = section length 8cm; span of 3 notes = section length 9cm.

[0062] The high and low pitches represent thicker bamboo joints:

[0063] Base tone = 2.0 times thicker; low tone = 1.5 times thicker;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com