Composite rib-composite material grating seawater and sea sand bridge deck slab

A composite material and composite rib technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems that bridge decks do not have anti-corrosion, cannot alleviate the shortage of river sand resources, and structural durability has not been solved, and achieve light weight. , The effect of strong fatigue resistance and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

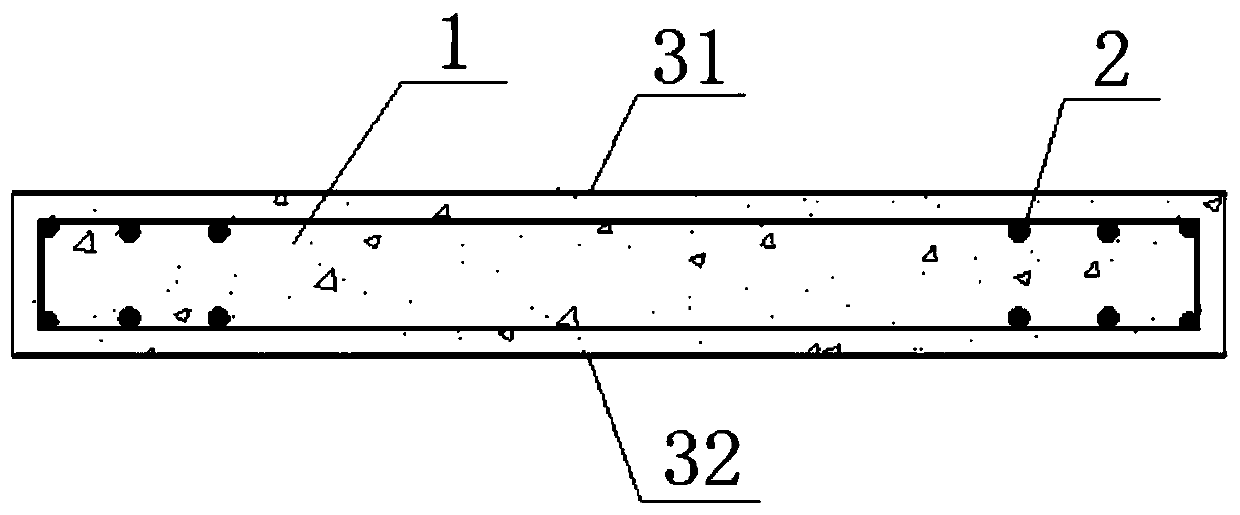

[0030] Such as Figure 1 to Figure 2 Shown is the first embodiment of a composite bar-composite material grid seawater sea sand bridge deck of the present invention, including an FRP grid structure 3, and a number of criss-crossing composite ribs 2 are arranged in the FRP grid structure 3, and the FRP grid The grid structure 3 is poured with concrete 1 .

[0031] The concrete 1 is constrained jointly by the FRP grid structure 3 and the composite reinforcement 2, so that the bearing capacity, stability and earthquake resistance of the bridge deck can be improved, and the corrosion resistance and bending resistance can also be improved.

[0032] In addition, the FRP grid structure 3 includes a first FRP grid 31 and a second FRP grid 32, the first FRP grid 31 is located on the upper surface or the lower surface of the second FRP grid 32, and the first FRP grid 31 and the second FRP grid The second FRP grids 32 are parallel to each other, and the concrete 1 is poured between the ...

Embodiment 2

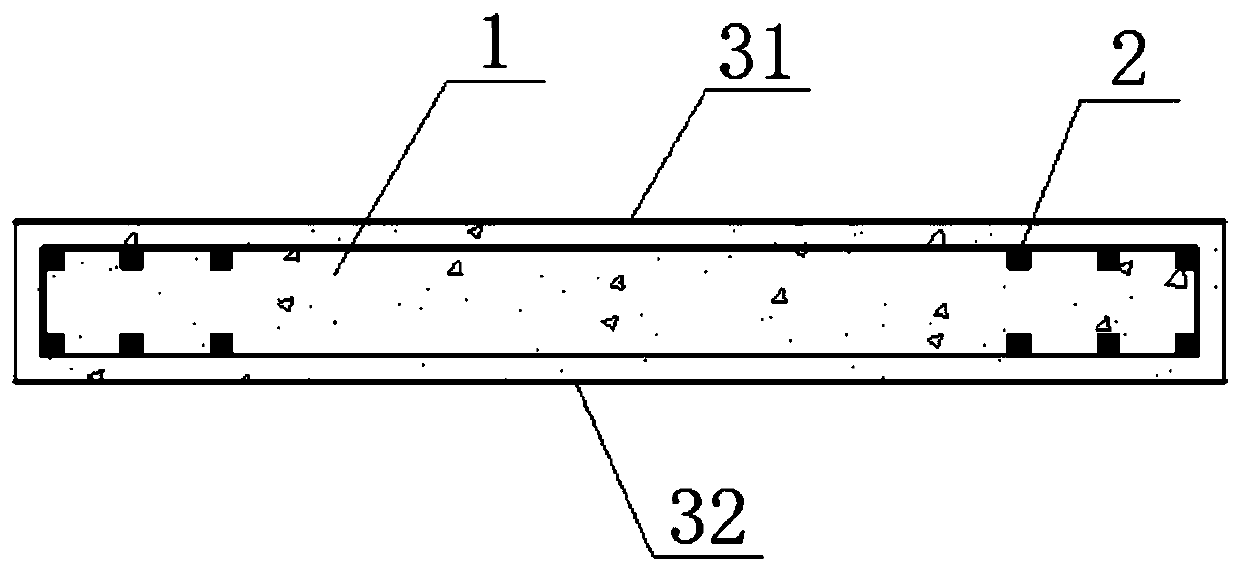

[0040] This embodiment is similar to Embodiment 1, the difference is that the cross-section of the composite bar 2 in this embodiment is square, as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com