Hydrodynamic retarder with front stator

A retarder and pre-hydraulic technology, applied in the direction of hydraulic resistance brakes, couplings, clutches, etc., can solve the problems of small retarder torque, no-load loss, and difficult spatial arrangement of hydraulic retarders, etc. The effect of increasing retarder torque, reducing weight, improving strength and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

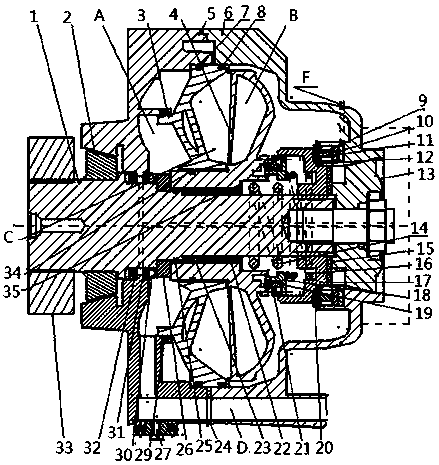

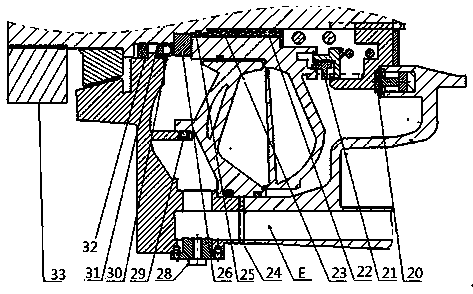

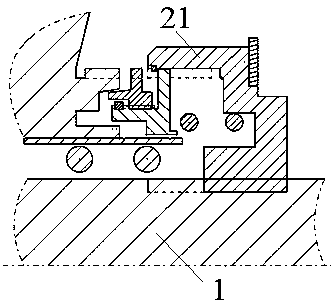

[0024] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Examples of the present invention figure 1 , figure 2 , image 3 As shown, it includes retarder shaft 1, front bearing 2, stator 3, rotor 4, stator end cover 5, body 6, stator sealing ring 7, rotor sealing ring 8, annular piston oil seal 9, annular meshing piston 10, Ring type end face bearing 11, ring type piston double seal 12, rear bearing 13, release spring 14, active meshing gear end face bearing 15, locking sliding frame return spring 16, meshing gear 17, locking sliding frame 18, synchronous lock Stop ring snap ring 19, end face bearing 20, synchronous lock ring 21, rotor needle roller bearing 22, rotor needle roller bearing positioning ring 23, oil return passage seal 24, rotor sealing ring 25, rotor positioning ring and end face bearing 26, Output temperature sensor 27, working chamber input oil temperature sensor 28, stator input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com