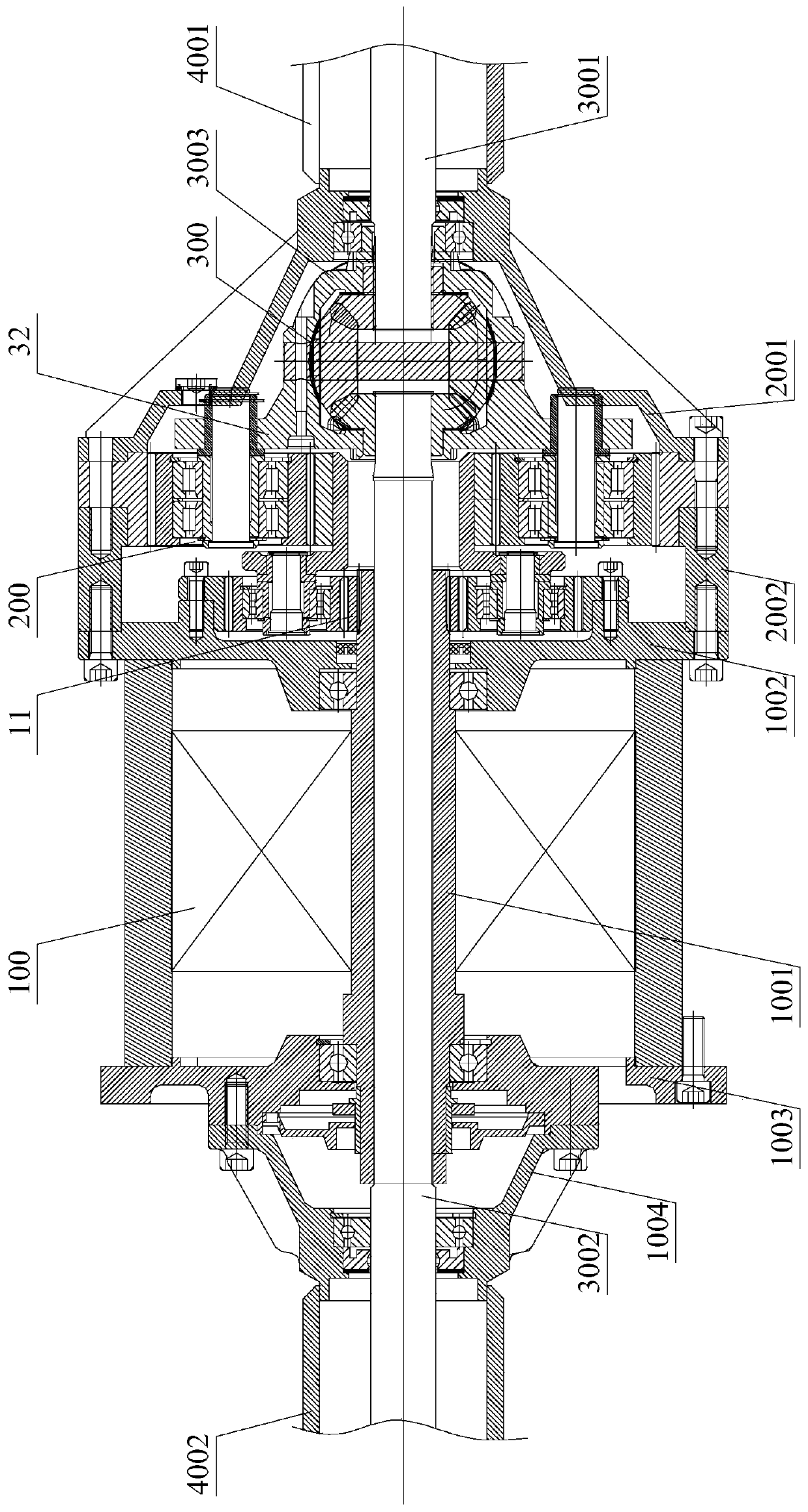

Electric drive axle of double-stage planetary gear reducer

A technology of gear reducer and planetary gear, which is applied in the direction of belt/chain/gear, transmission parts, mechanical equipment, etc., can solve the problems of difficult load distribution, system vibration and noise, and tight space layout, etc., to achieve optimized rear axle layout Effects of space, cost reduction, and structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

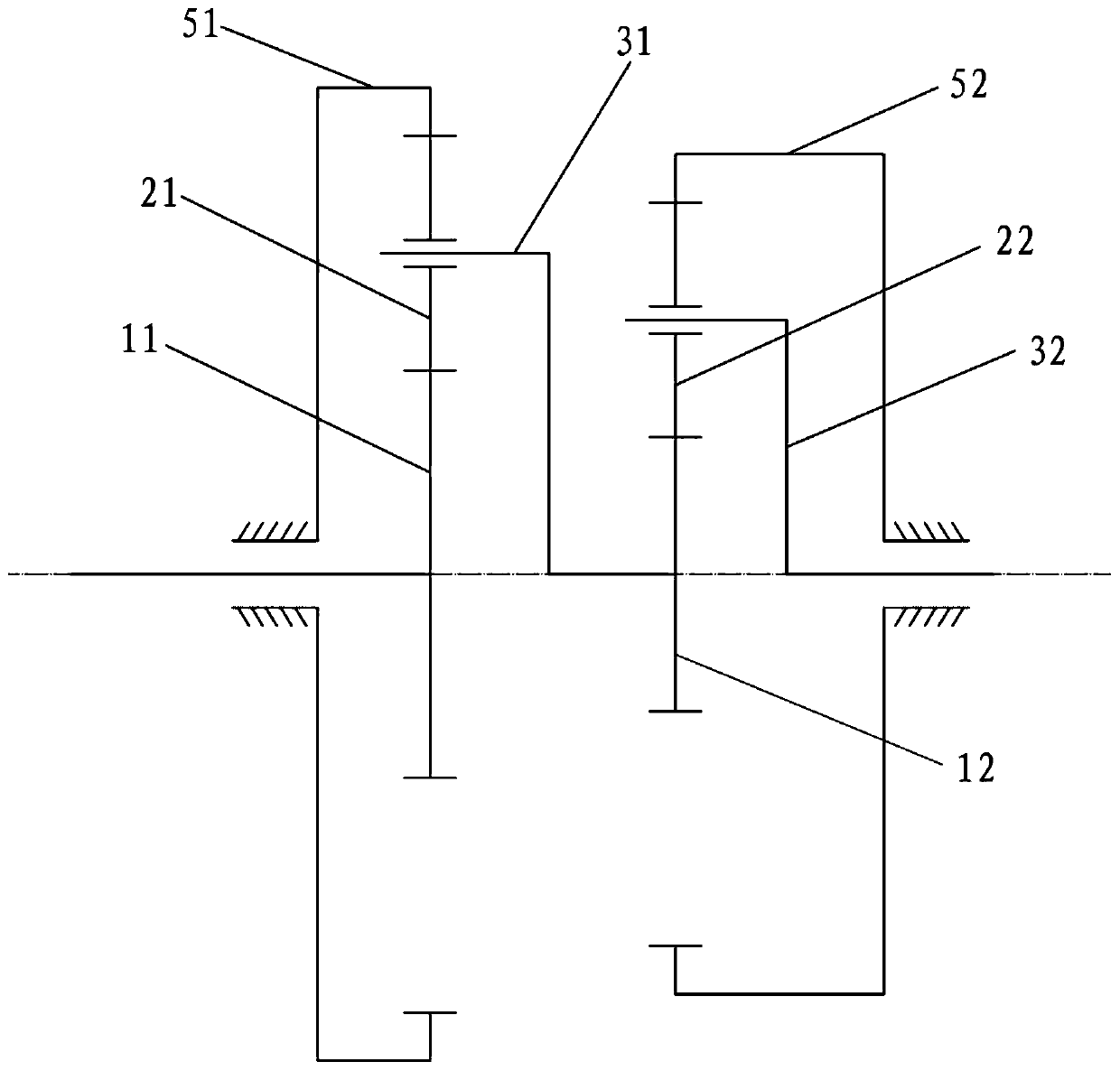

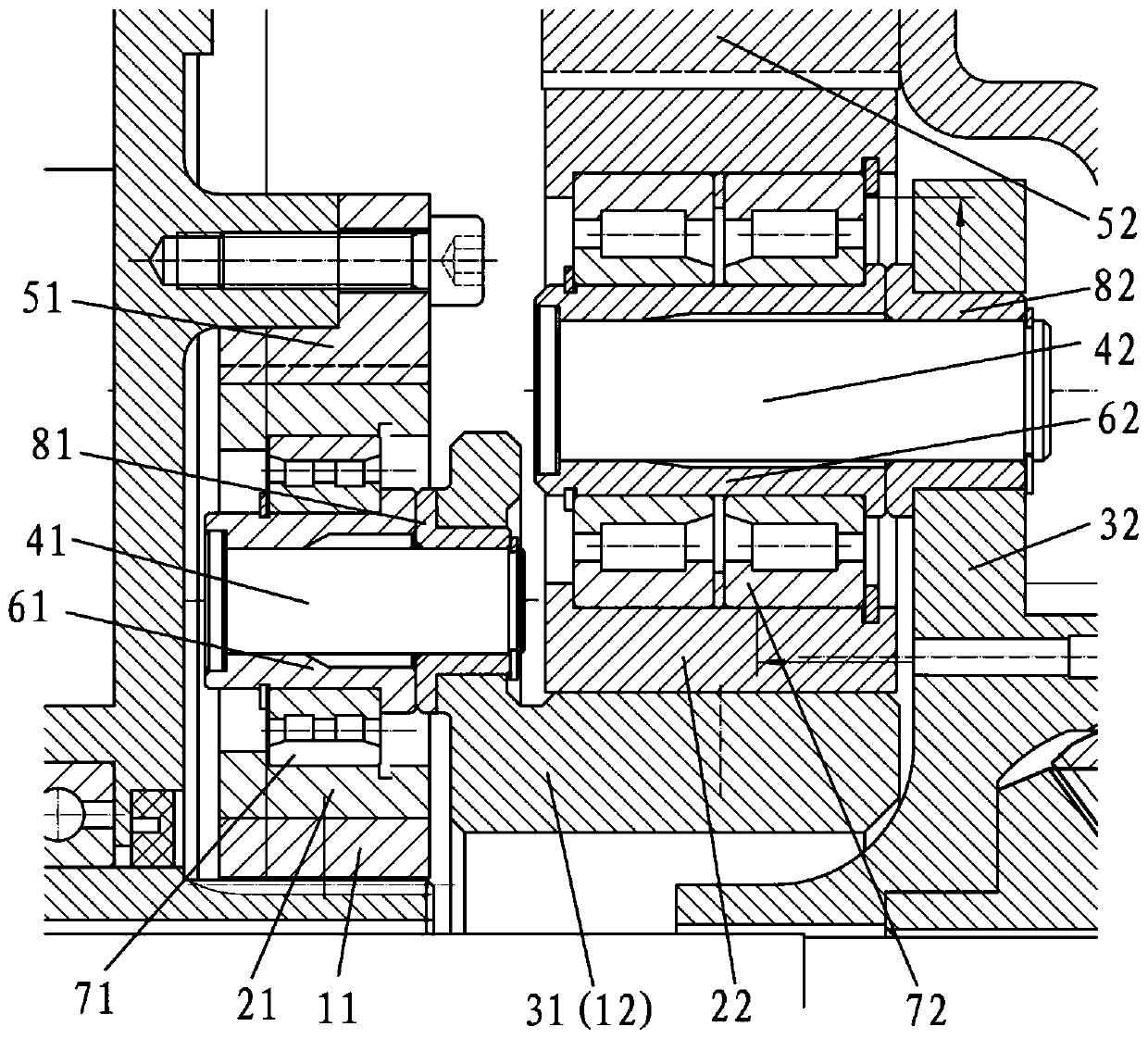

[0052] See Figure 4 , the two ends of the planetary pin shaft 40 (41) are respectively inserted into the mounting holes of the planetary gear 20 (21) and the planetary carrier 30 (31), forming the basic connection relationship of the planetary gear 20, and respectively constructing the planetary gear train to meet the transmission requirements. Corresponding radial positioning of the relationship.

[0053] In order to more clearly describe the composition and mechanism of the load-sharing structure, here, the inner section of the installation hole of the planetary wheel 20 that is opposite to the planet carrier 30 is defined as the first hole section 601, and the installation hole of the planet carrier 30 is opposite to the planetary wheel 20. The inner section of is the second hole section 801. The orientation words such as "inner" and "outer" used in this article are defined on the basis of the matching relationship between the matched planetary gear 20 and the planetary c...

Embodiment 2

[0066] This solution is consistent with the main design concept of the load sharing structure provided in Embodiment 1, the only difference is that the planetary pin shaft 40 is a stepped shaft, and the small diameter section 401 of the stepped shaft and the first hole section of the mounting hole on the side of the planetary wheel 20 601 forms a preset radial gap δ, and the diameter of the large-diameter section 402 of the stepped shaft is the same as the radial dimension of the mounting hole of the adapter section. See Figure 8 , this figure is a schematic diagram of the load sharing structure described in this embodiment. In order to clearly show the differences and connections between this solution and the foregoing embodiments, the same functional components and structures are shown with the same symbols in the figure.

[0067] As shown in the figure, the planetary gear 20 on the planetary gear train forms a cantilever beam-like structure from the center points correspon...

Embodiment 3

[0069] This solution is consistent with the main design concept of the load sharing structure provided in Embodiments 1 and 2, the only difference is that the diameter of the first hole section 601 is larger than the diameter of the outer section 603 of the mounting hole, and the planetary pin shaft 40 is a stepped shaft, A preset radial gap δ is formed between the small-diameter section 401 of the stepped shaft and the first hole section 601 of the mounting hole on the side of the planetary wheel 20, and the diameter of the large-diameter section 402 of the stepped shaft is the same as the diameter of the outer section 603 of the mounting hole of the adapter section. to the same size. See Figure 9 , this figure is a schematic diagram of the load sharing structure described in this embodiment. In order to clearly show the differences and connections between this solution and the foregoing embodiments, the same functional components and structures are shown with the same symbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com