Nuclear-grade pneumatic gate valve

A kind of pneumatic gate valve, nuclear-grade technology, applied in sliding valve, valve details, valve device and other directions, can solve the problems of poor shock resistance, simple structure, high-end valve dependence on imports, etc., to reduce weight and volume, reduce axial force , the effect of reducing weight and height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

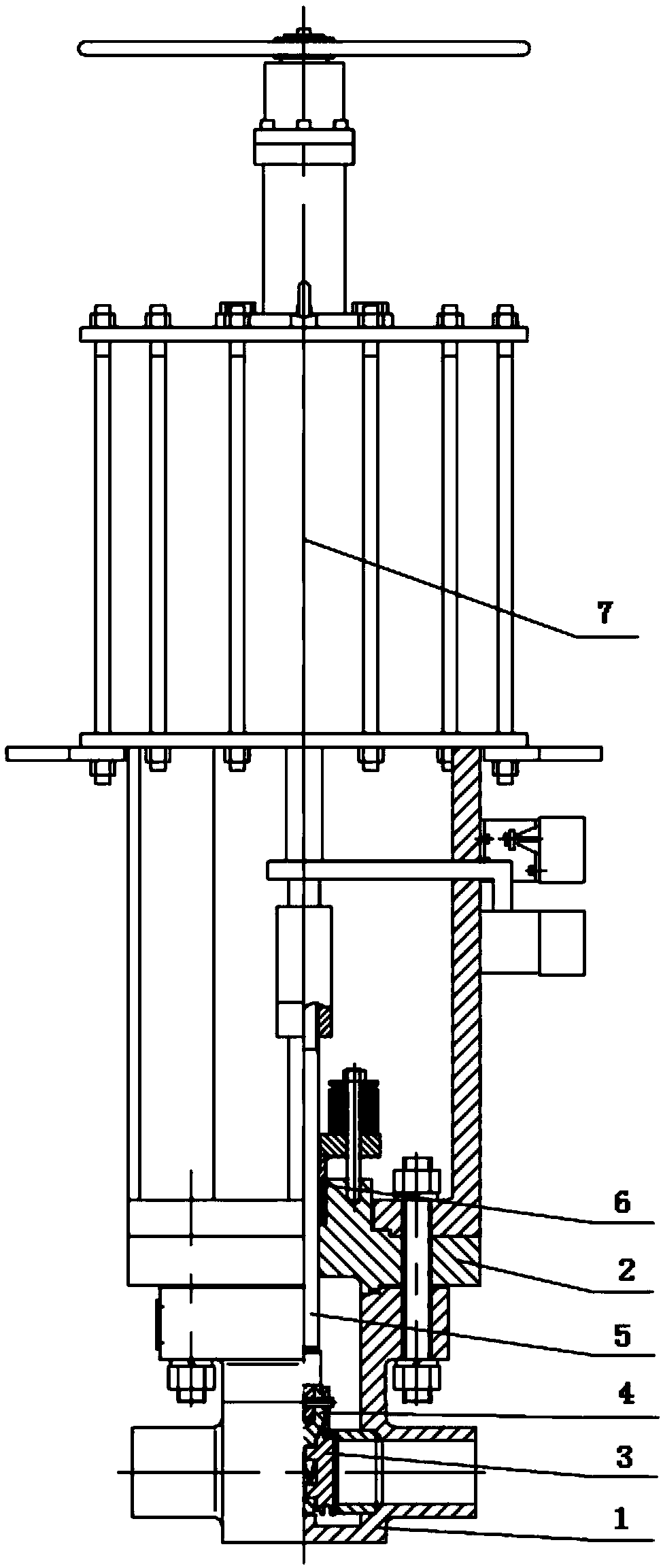

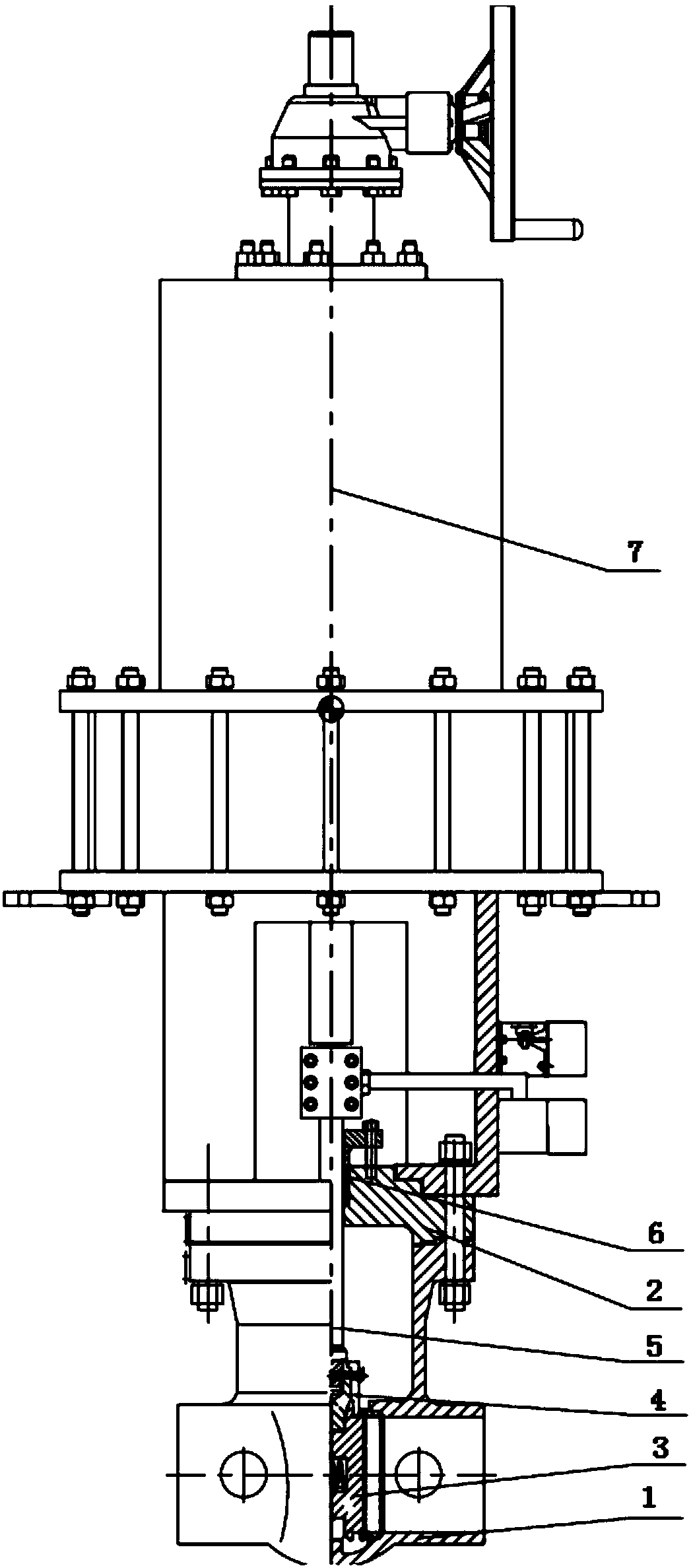

[0015] as attached Figure 1~2 As shown, a nuclear-grade pneumatic gate valve is provided with a valve cover on the lowermost valve body, a pneumatic actuator is installed on the valve cover, and a connecting rod is installed in the center of the pneumatic actuator, and the connecting rod is fixedly connected with the valve stem. The ram frame ram is set, the ram is set on the ram frame, and the packing is also set on the valve cover.

[0016] The valve body, valve cover and pneumatic actuator are integrally connected by middle flange studs.

[0017] The gate is a spring-type parallel double gate structure, which will not cause wedging phenomenon under high temperature, and can effectively reduce the axial force of valve opening and closing, and reduce the weight and volume of the pneumatic actuator.

[0018] The upper seal is set at the connection between the valve stem and the valve cover, and the valve seat seal is set at the joint between the valve body and the gate plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com