Microwave gain type CO2 phase change cumulative blasting rock breaking system and blasting rock breaking method

A gain-type, CO2 technology, applied in the field of rock breaking, can solve the problems of low blasting power, inability to achieve energy gathering, and limit the amount and speed of blasting gas release, and achieve the effect of increasing blasting intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

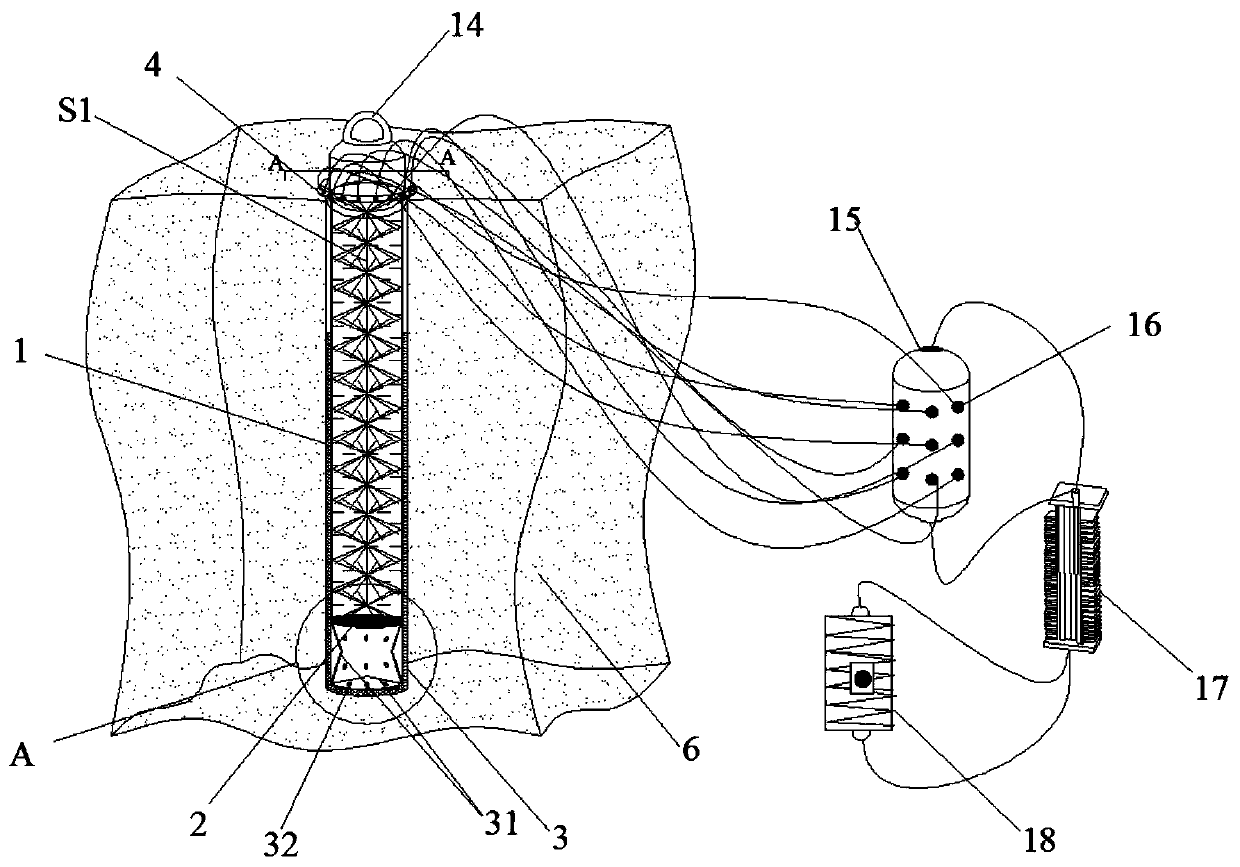

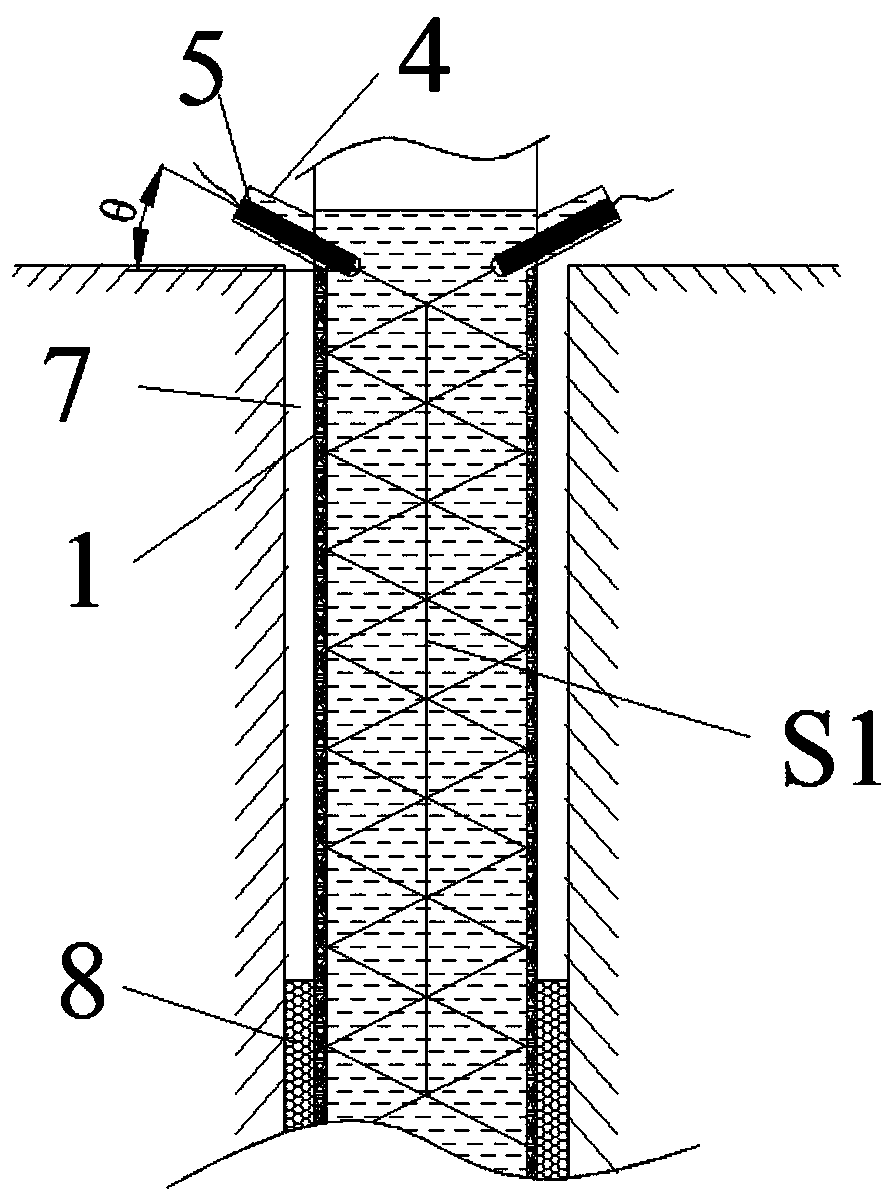

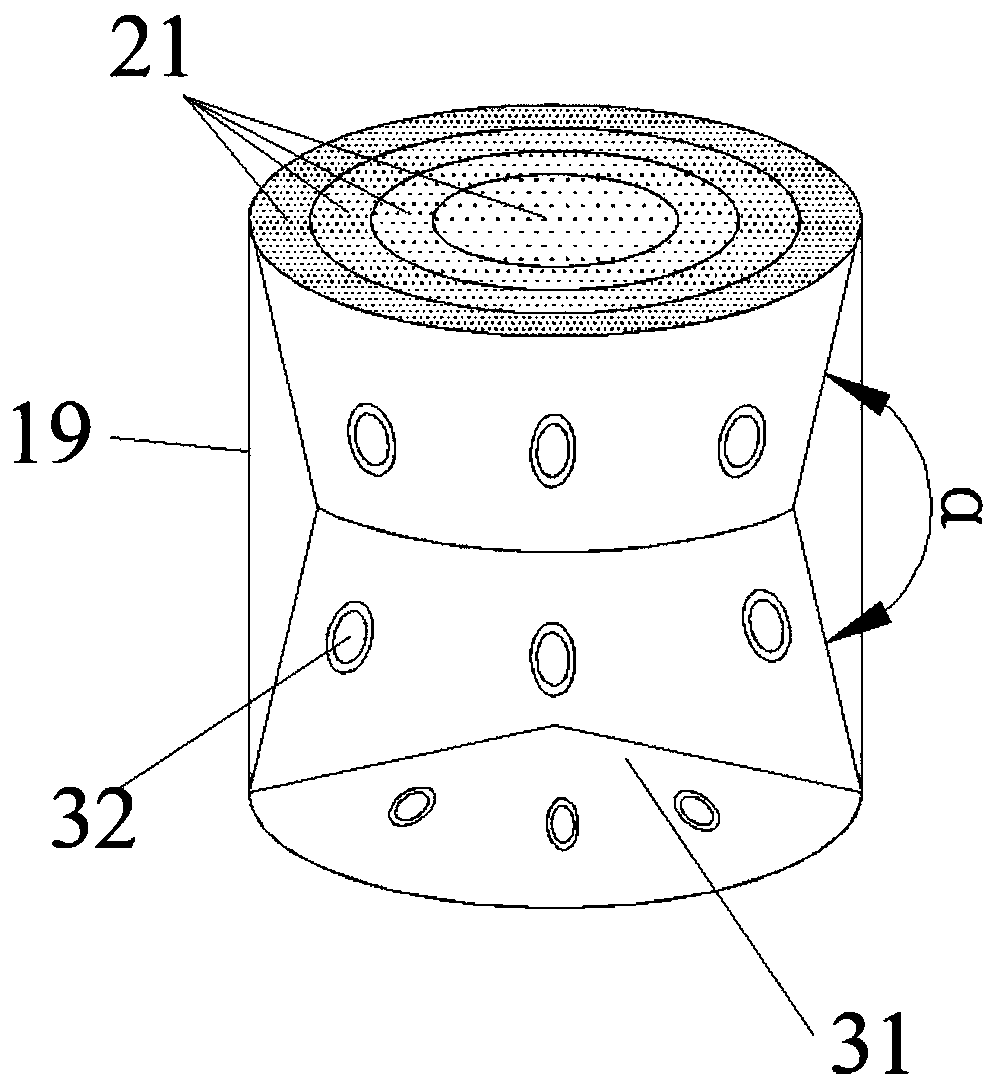

[0029] Such as Figure 1-Figure 3 As shown, the microwave gain type CO of this embodiment 2 Phase change concentrated energy blasting rock breaking system, including liquid CO 2 Phase change tubes and for heating liquid CO 2 Liquid CO in a phase change tube 2 heating system, liquid CO 2 The phase change tube includes a liquid storage tube 1, a constant pressure shear piece assembly 2 and an energy discharge head 3. The energy discharge head 3 is arranged under the liquid storage pipe 1, and the constant pressure shear piece assembly 2 is arranged between the liquid storage pipe 1 and the energy discharge head. Between the heads 3, the heating system is used to emit microwaves into the liquid storage tube 1 to heat the liquid CO in the liquid storage tube 1 2 microwave heating system.

[0030] In this embodiment, the microwave heating system includes a microwave source, a plurality of microwave transmitter storage bins 4 and a plurality of microwave transmitters 5, the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com