Pulse shunt

A shunt and pulse technology, used in instruments, voltage/current isolation, measurement devices, etc., can solve problems such as the inability to meet the measurement needs of high pulse current measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the characteristics and technical content of the present application in more detail, the implementation of the present application will be described in detail below in conjunction with the accompanying drawings. The attached drawings are only for reference and description, and are not used to limit the present application.

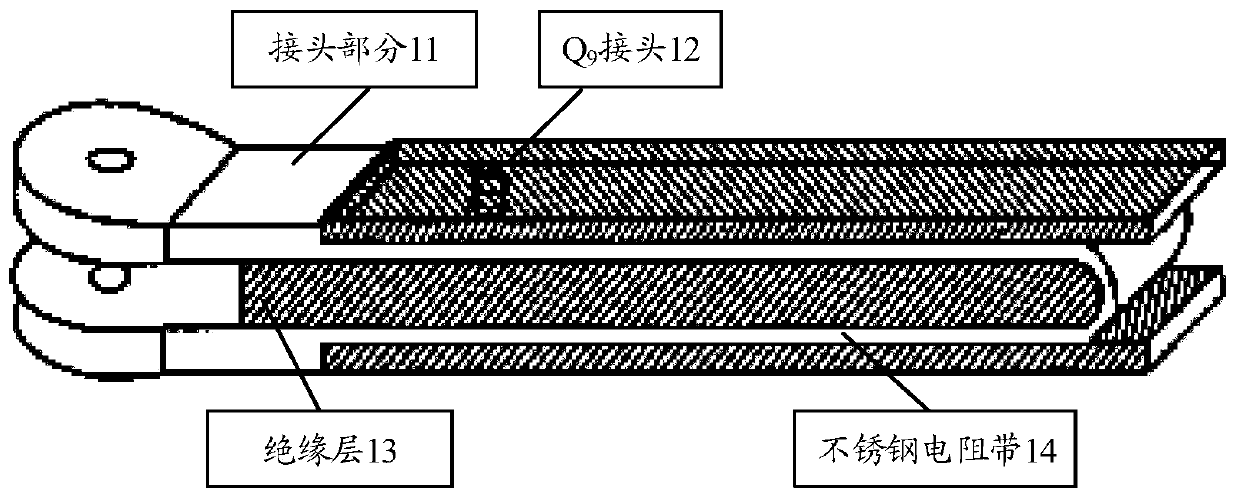

[0024] In one embodiment, using figure 1 The pulse shunt of the folded structure is shown. The pulse shunt of the double-fold structure usually adopts a thin stainless steel resistance. The current end of the pulse shunt is welded with an oxygen-free copper sheet and a stainless steel resistance band, and the core wire of the voltage end is welded with the lower layer of the resistance band. connect. The advantage of the pulse shunt with a folded structure is that it is simple in structure and easy to manufacture, but the pulse shunt with a folded structure has a large residual inductance when it is used, which will bring a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com