Installation and method for producing glued plant particles

A technology of plant particles and equipment, applied in chemical instruments and methods, manufacturing tools, applications, etc., can solve problems such as interference with the production process and high wear and tear of equipment components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

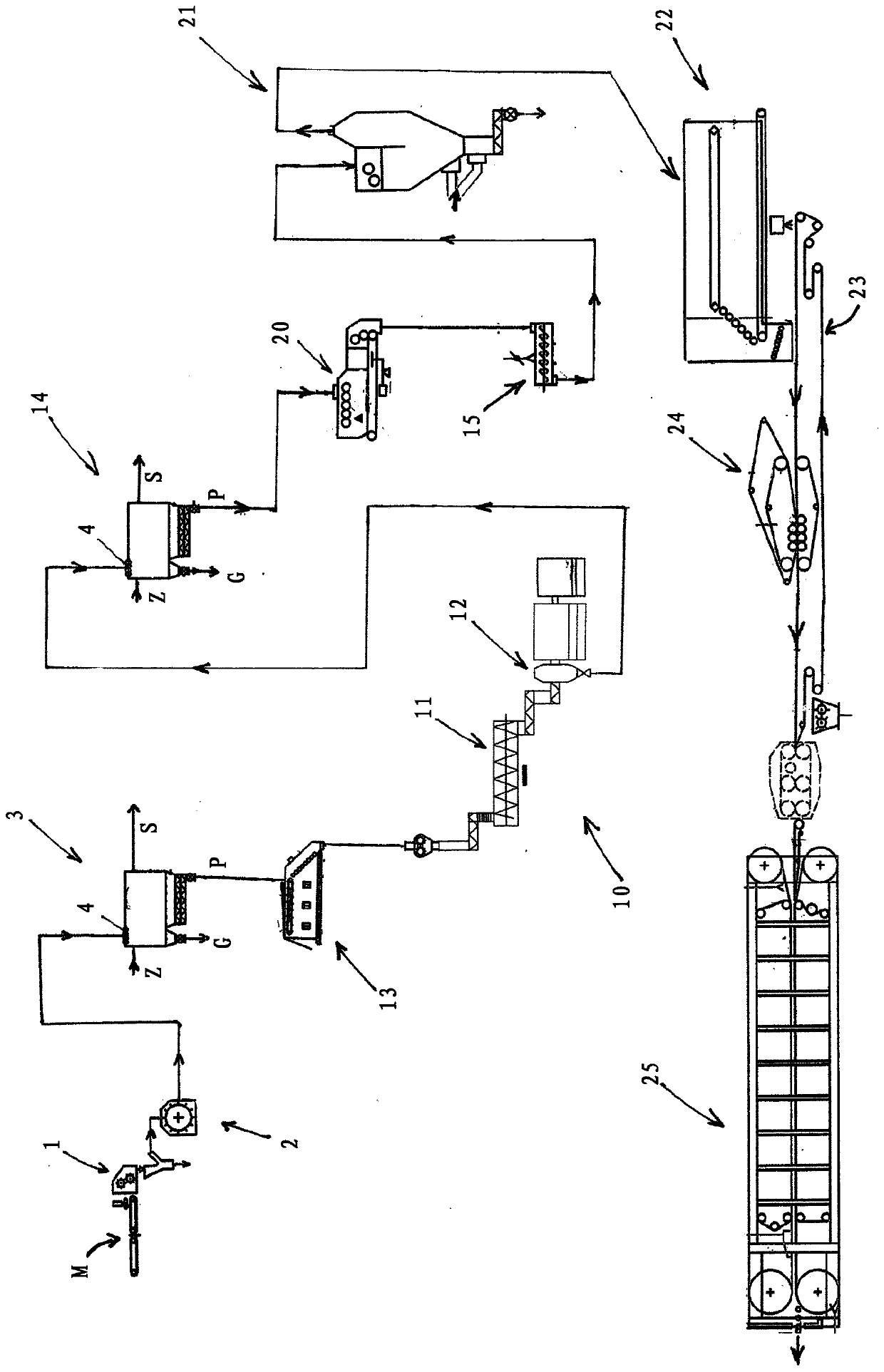

[0031] figure 1 A plant is shown with which glued vegetable particles, for example glued fibers produced from annual plants, for example straw and particularly preferably rice straw, are pressed into boards.

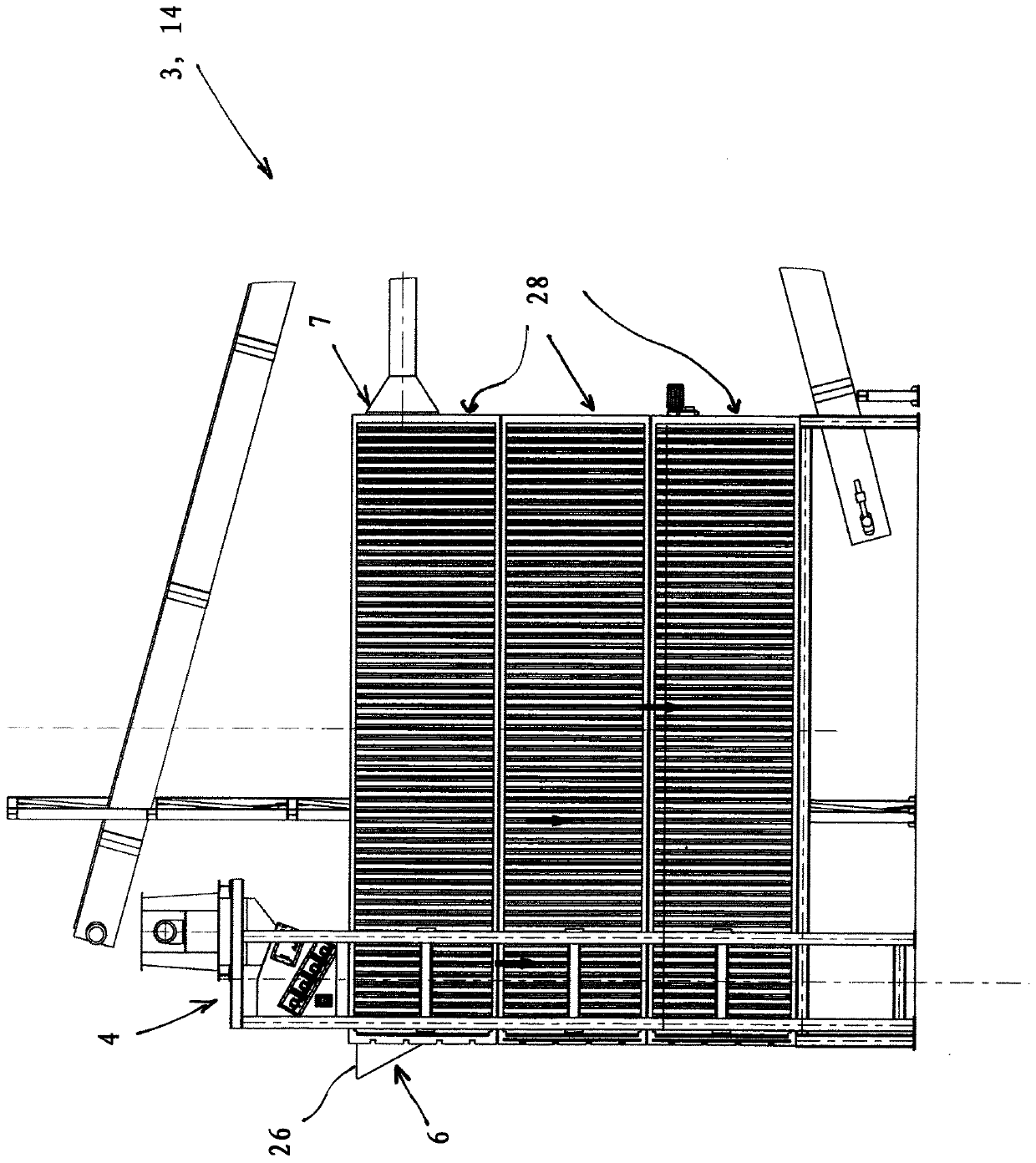

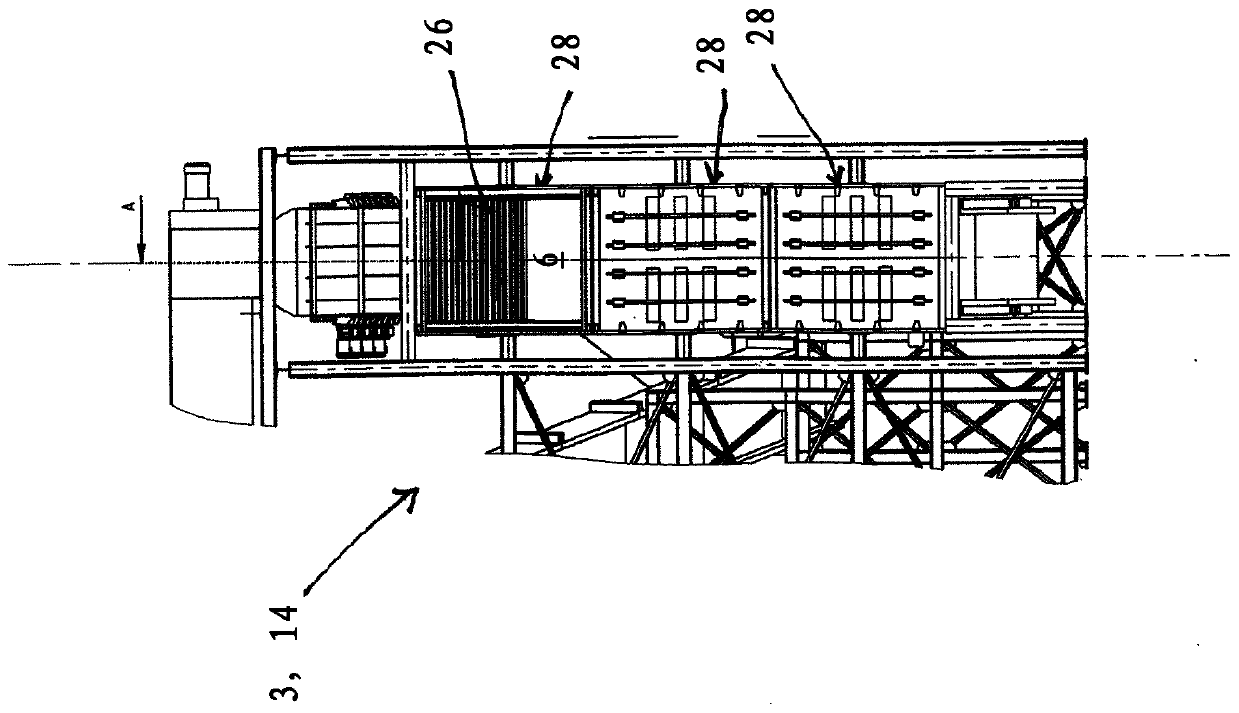

[0032] Straw, which is available as raw material M, is crushed in a first crushing device 2 , which is designed as a hammer mill 2 in the exemplary embodiment, after pre-crushing, for example, in a straw shredder 1 . The material produced in this first crushing device 2 is fed to a first screening device 3 which forms a first screening stage for separating silicate particles from straw particles. The first screening device 3 is enlarged in Figure 2 to Figure 5 Shown in , the first screening device will be discussed in detail below.

[0033] In such a sieving device 3 designed as a wind sifter, the straw particles are introduced into the sifter housing 5 via the upper material inlet 4 and are acted upon by an air flow (supply air Z) in the sifter housing. ). For this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com