Artificial pinellia ternata cultivation substrate and preparation method thereof

A technology of artificial cultivation and substrate, which is applied in the direction of planting substrate, botany equipment and methods, culture medium, etc., can solve the problems of unfavorable accumulation of effective substances, poor quality, and low quality of Pinellia pinellia, so as to improve the appearance quality, improve quality, The effect of increasing economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

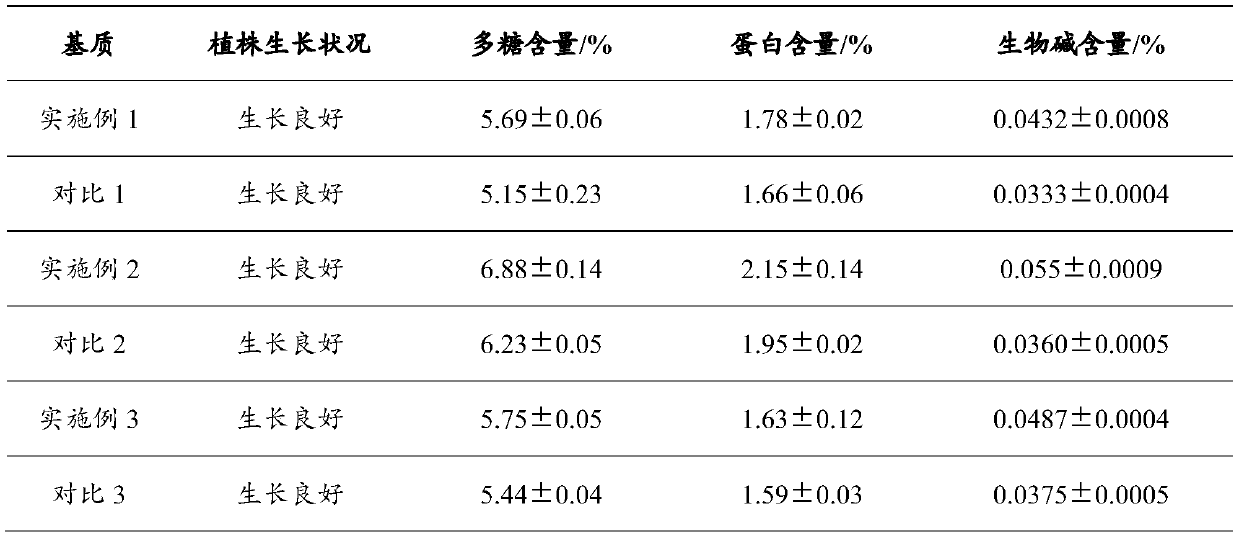

Examples

Embodiment 1

[0022] This embodiment is to prepare a kind of artificial cultivation pinellia substrate, which is prepared according to the following raw material formula: saline soil: river sand: humus soil: pine bark: perlite volume ratio=3:2:2:1:0.5. The specific preparation method is as follows:

[0023] First, prepare the saline soil. Get the field plow layer soil (the soil taken in this embodiment is the cultivated land soil located in Jianbi Town, Zhenjiang, Jiangsu Province. Its soil quality is soft and needs to be treated with soluble salts to become hard garden soil.) Place it in the sun for exposure, and sieve out Pebbles and grass roots are disinfected and placed in special containers, and chloride salts or sulfates are applied in stages. The container is a plastic tray specially customized for the door, with a depth of 30cm. Because the soil should be thoroughly watered with salt water, it is not suitable to place an overly thick soil layer, generally 20-25cm. The chloride sal...

Embodiment 2

[0027] This embodiment also prepares a kind of artificial cultivation pinellia substrate, which is prepared according to the following raw material formula: saline soil: river sand: humus soil: pine bark: perlite volume ratio=4:3:3:2:1. The preparation method of this example is the same as that of Example 1, except that the components of the humus used in parts by weight are: 25 parts of grass felt soil, 12 parts of black felt soil, and 15 parts of decomposed straw fertilizer.

Embodiment 3

[0029] In this embodiment, a kind of artificial cultivation pinellia substrate is prepared, which is prepared according to the following raw material formula: saline soil: river sand: humus soil: pine bark: perlite volume ratio=5:4:4:3:2. The preparation method of this embodiment is also the same as that of Example 1, except that the components of the humus soil used in parts by weight are: 30 parts of grass felt soil, 15 parts of black felt soil, and 20 parts of decomposed straw fertilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com