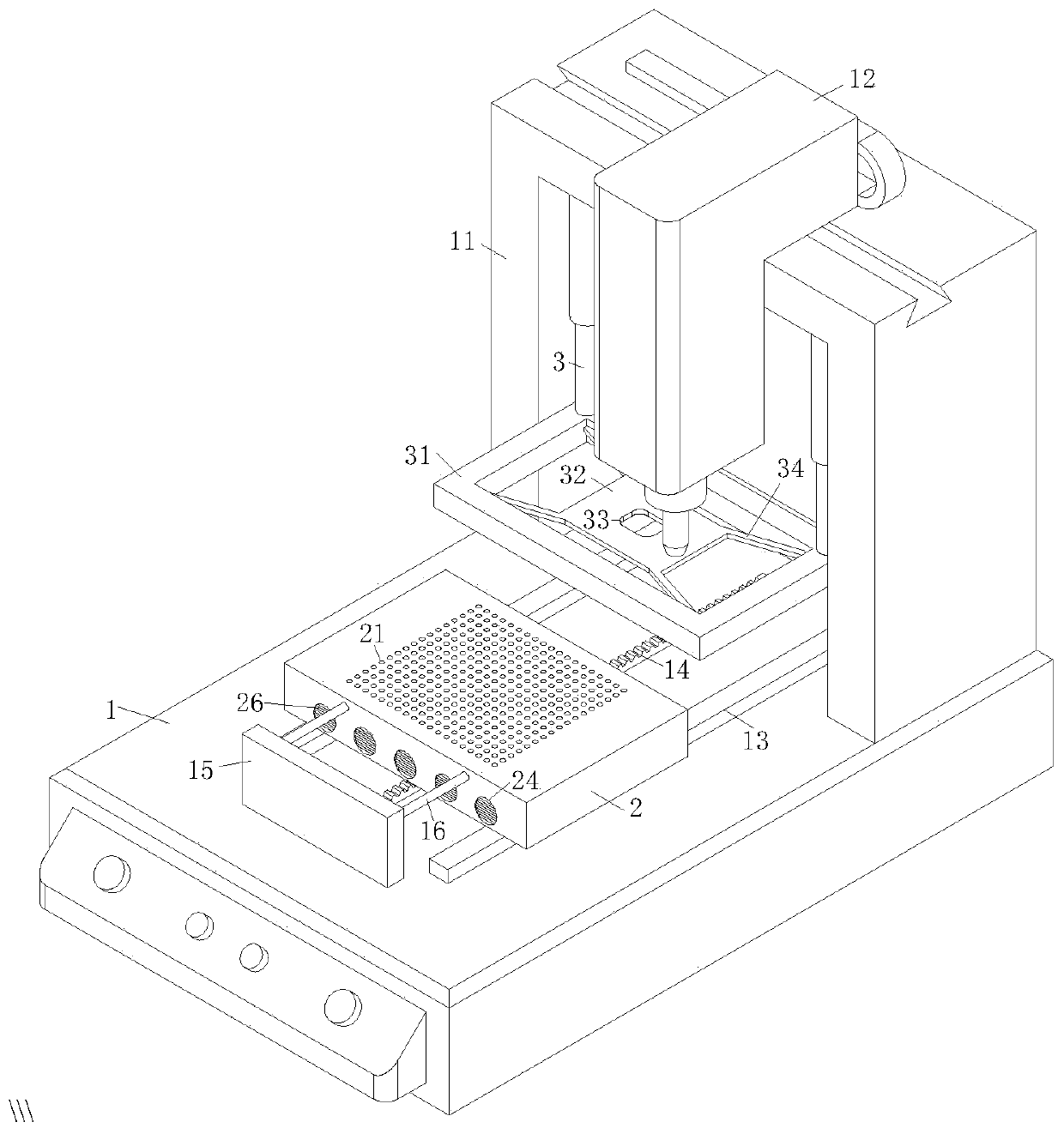

FPC welding machine

A welding machine and welding device technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easily damaged FPC temperature, difficult to guarantee, and unstable welding quality, so as to ensure welding quality and reduce Thermal influence, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

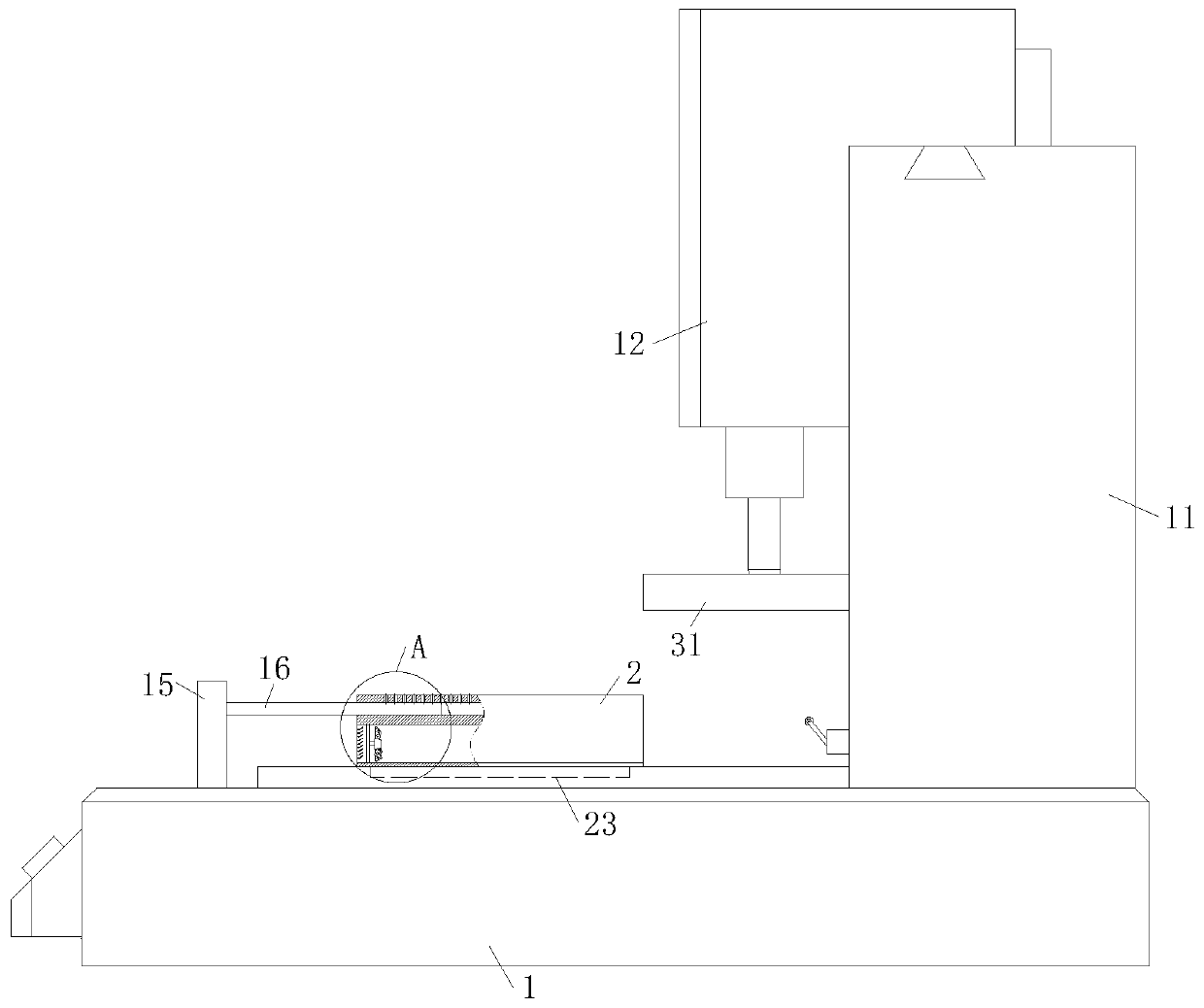

Method used

Image

Examples

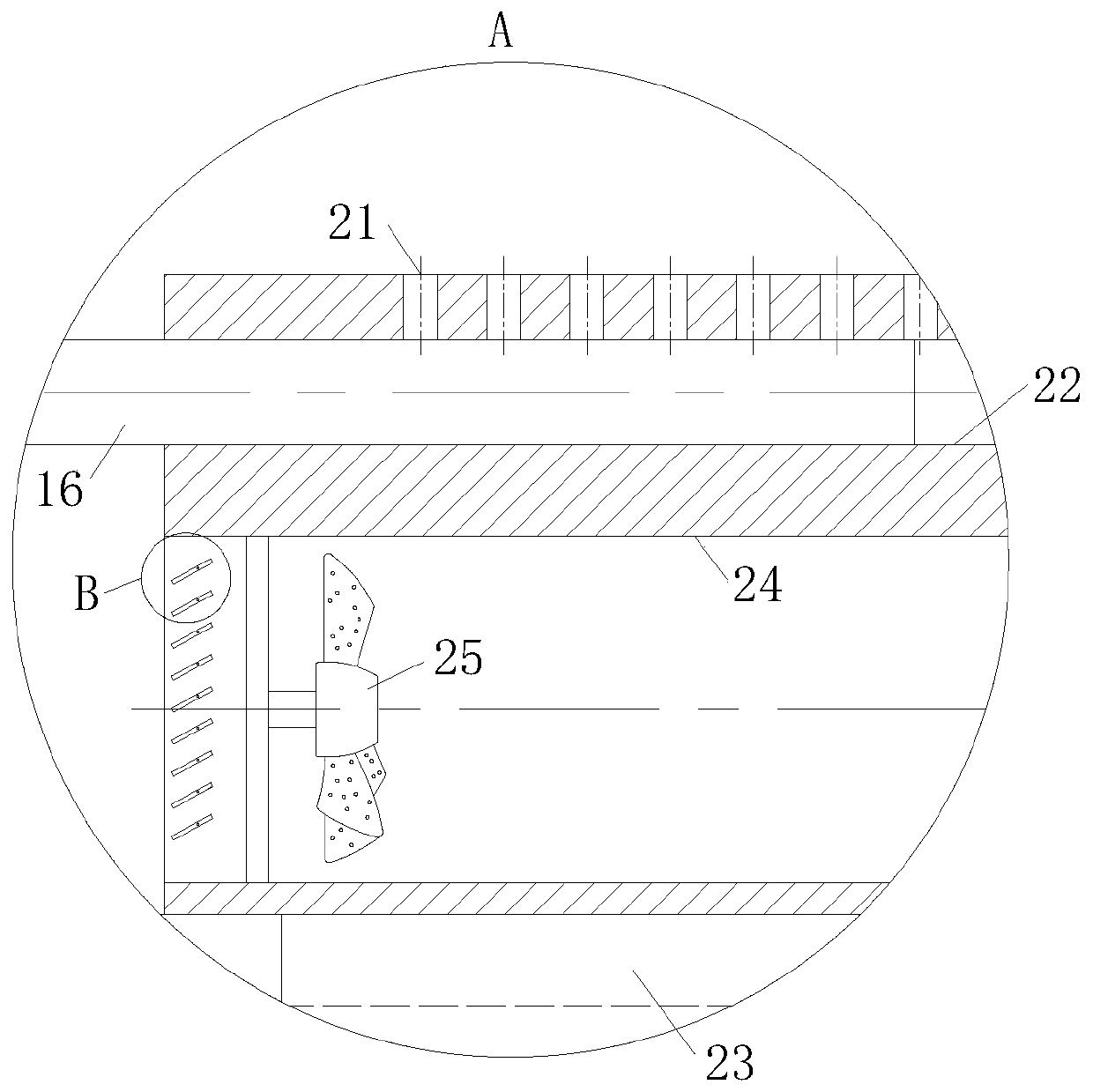

Embodiment approach

[0024] As an embodiment of the present invention, a limiting plate 15 is fixedly connected to the body 1 of the slide table 2 away from the side of the gantry 11, and a group of sliding columns 16 are fixedly connected to the limiting plate 15, and the sliding columns 16 are far away from the limiting plate. One end of the position plate 15 is inserted in the air extraction hole 22 and is slidably and sealedly connected with the air extraction hole 22; when the sliding table 2 is away from the limit frame, the sliding column 16 increases the air extraction effect on the air extraction hole 22; Limit the sliding table 2 to prevent the stroke from exceeding, and at the same time cooperate with the sliding column 16, so that when the sliding table 2 slides in a direction away from the limit block, the sliding column 16 is drawn out relative to the air extraction hole 22, thereby further increasing the suction of the air extraction hole 22. Improve the gas efficiency, increase the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com