Soil oxidation restoration agent, preparation method and use method thereof

An oxidation remediation and soil technology, applied in the field of contaminated soil remediation, can solve problems such as damage to the internal structure of the soil, soil fertility decline, soil pollution, etc., and achieve the effects of reducing soil density, loosening soil, and low preparation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

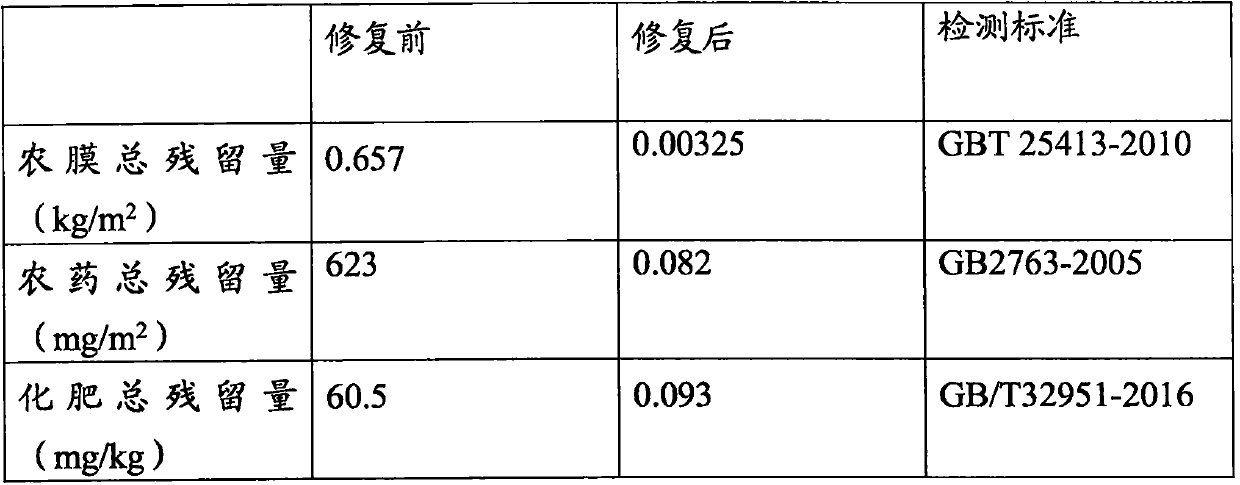

Embodiment 1

[0033] The soil oxidation remediation agent of the present invention weighs raw materials according to the following parts by weight: 1 kg of diatomite, 0.2 kg of 27.5% industrial hydrogen peroxide, 0.005 kg of titanium dioxide powder, 1 kg of biochar, 0.01 kg of anhydrous ferrous sulfate powder, and 7.785 kg of water.

[0034] The preparation method of above-mentioned soil oxidation remediation agent, comprises the steps:

[0035] (1) put diatomite into a stone crusher and pulverize to 80 mesh, obtain diatomite powder for subsequent use;

[0036] (2) Mix the anhydrous ferrous sulfate powder and titanium dioxide powder and the diatomite powder in the step (2) to obtain component A;

[0037] (3) Mix the hydrogen peroxide and the water evenly to obtain component B;

[0038] (4) Put the biochar into a stone crusher and pulverize it to 100 mesh, and obtain the biochar powder as component C.

[0039] The using method of above-mentioned soil oxidation remediation agent, comprises ...

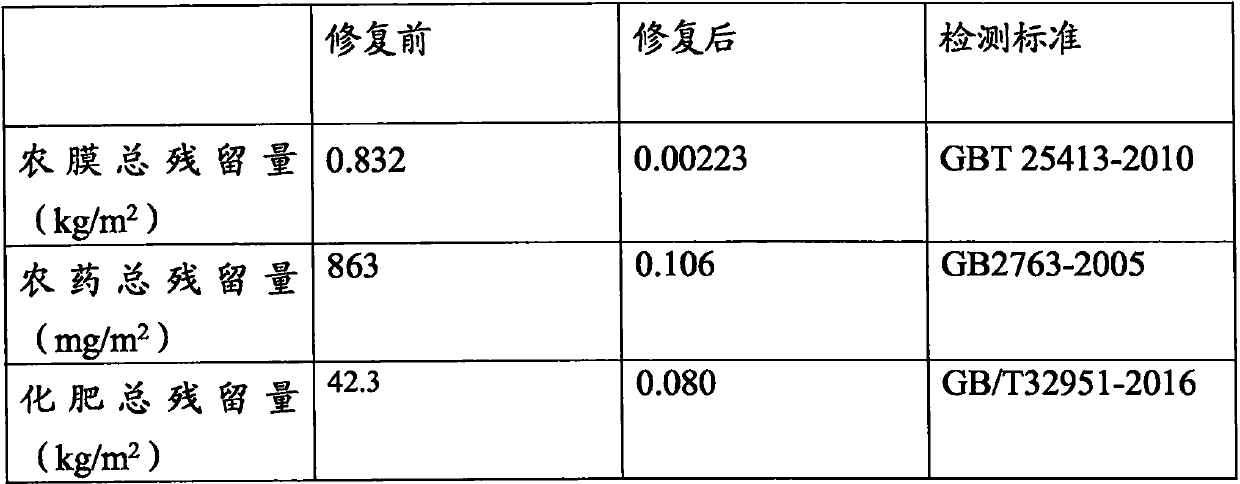

Embodiment 2

[0046] The soil oxidation remediation agent of the present invention takes raw materials according to the following parts by weight: 2kg of diatomite, 0.5kg of industrial hydrogen peroxide of 27.5%, 0.006kg of titanium dioxide powder, 0.8kg of biochar, 0.05kg of anhydrous ferrous sulfate powder, and 6.644kg of water .

[0047] The preparation method of above-mentioned soil oxidation remediation agent, comprises the steps:

[0048] (1) Diatomite is put into a stone crusher and pulverized to 100 mesh, and diatomite powder is obtained for subsequent use;

[0049] (2) Mix the anhydrous ferrous sulfate powder and titanium dioxide powder and the diatomite powder in the step (2) to obtain component A;

[0050] (3) Mix the hydrogen peroxide and the water evenly to obtain component B;

[0051] (4) Put the biochar into a stone crusher and pulverize it to 90 mesh, and obtain the biochar powder as component C.

[0052] The using method of above-mentioned soil oxidation remediation agent,...

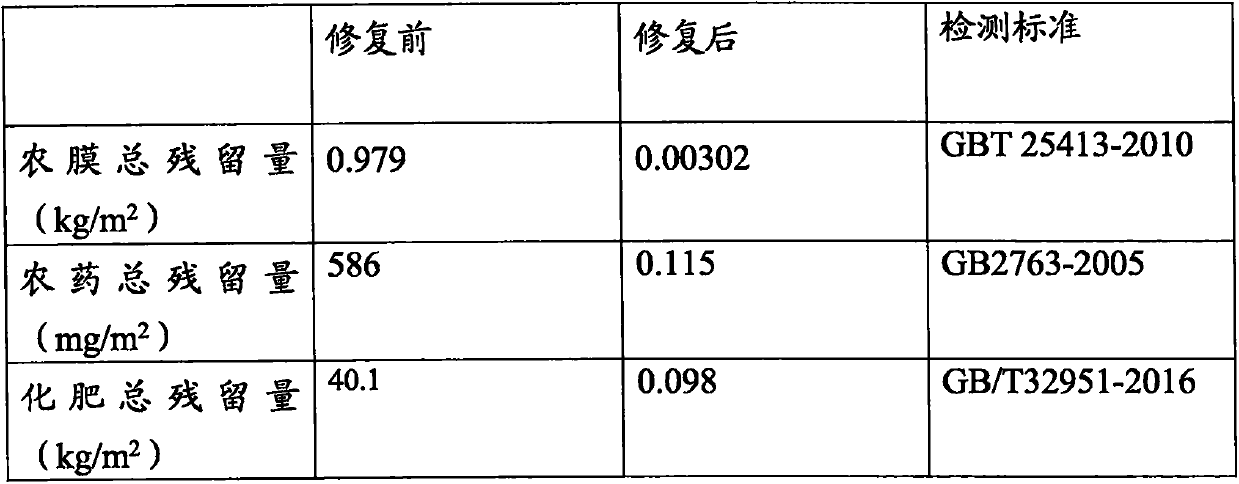

Embodiment 3

[0059] The soil oxidation remediation agent of the present invention takes raw materials according to the following parts by weight: diatomite 1.5kg, 27.5% industrial hydrogen peroxide 0.3kg, titanium dioxide powder 0.008kg, biochar 0.9kg, anhydrous ferrous sulfate powder 0.08kg, water 7.212 kg.

[0060] The preparation method of above-mentioned soil oxidation remediation agent, comprises the steps:

[0061] (1) Put diatomite into a stone crusher and pulverize to 90 mesh, obtain diatomite powder for subsequent use;

[0062] (2) Mix the anhydrous ferrous sulfate powder and titanium dioxide powder and the diatomite powder in the step (2) to obtain component A;

[0063] (3) Mix the hydrogen peroxide and the water evenly to obtain component B;

[0064] (4) Put the biochar into a stone crusher and pulverize it to 80 mesh, and obtain the biochar powder as component C.

[0065] The using method of above-mentioned soil oxidation remediation agent, comprises the steps:

[0066] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com