Combined component supporting tooling system and construction method thereof

A combination and component technology, which is applied to the preparation of building components on site, pillars, building structures, etc., can solve the problems of restricting the construction efficiency and quality of prefabricated components, low construction efficiency, and large space occupation, so as to improve the construction quality , Convenient construction and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

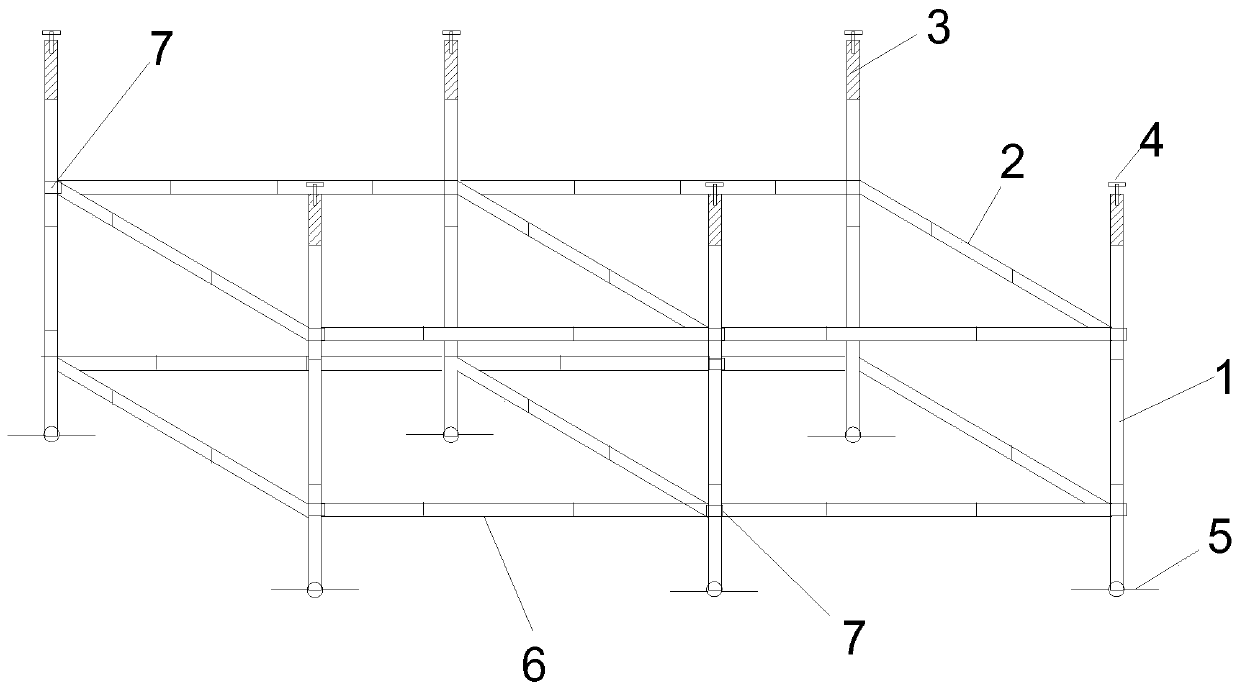

[0035] Such as figure 1 As shown, this embodiment provides a combined component support tooling system, which includes a plurality of single-panel bent racks spliced in sequence.

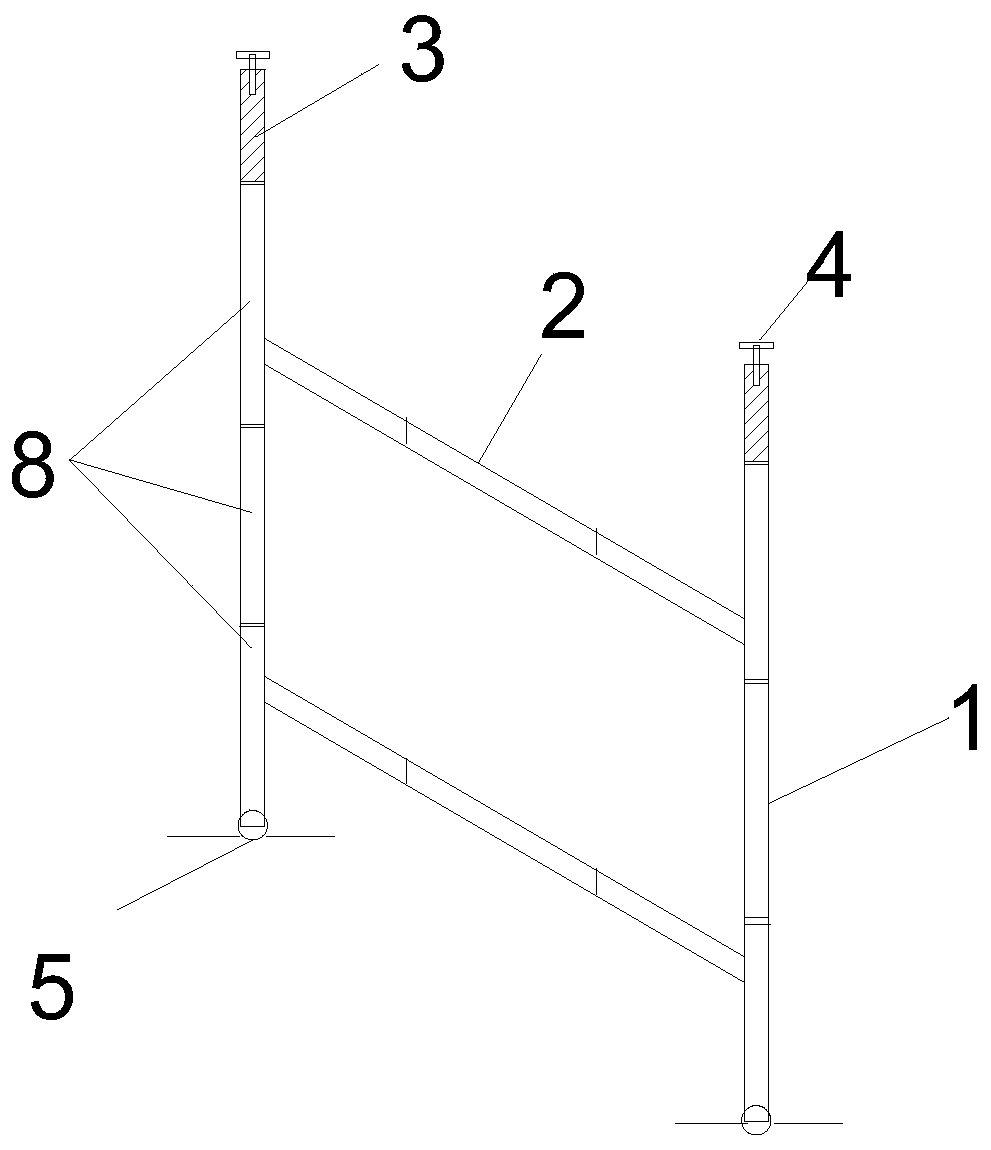

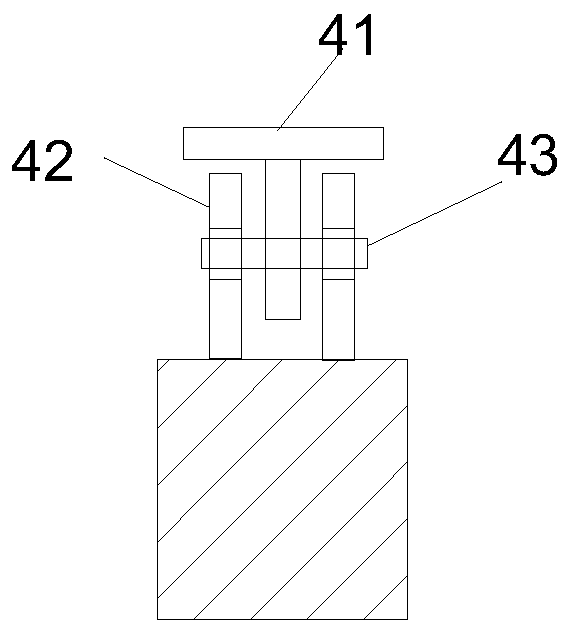

[0036] Such as figure 2 As shown, the single door-type bent frame includes a frame structure composed of a horizontal support rod 2 and a vertical support rod 1, and also includes a servo electric cylinder 3 arranged on the upper end of the vertical support rod 1, and a servo electric cylinder 3 arranged on the upper end of the vertical support rod 1. The rotating backing plate 4 on the top, and the support 5 arranged at the bottom of the vertical support bar 1 .

[0037] A preferred embodiment is, as figure 2 As shown, the vertical support rod 1 includes a number of standard rods 8 spliced in sequence, the ends of the standard rods 8 are provided with matching internal threads and external threads, and the standard rods 8 are screwed in turn, and the standard The rods 8 can effectively red...

Embodiment 2

[0048] This embodiment provides a construction method of a combined component support tooling system, which will be further introduced below in conjunction with Embodiment 1 and the accompanying drawings. Described construction method comprises the steps:

[0049] Step 1. Determine the shape and size of the combined component support tooling system according to the size and shape of the prefabricated component, determine the length and quantity of the vertical support bar 1, the horizontal support bar 2, and the horizontal bar 6; and determine the length and quantity of the standard bar 8 Quantity; while the quantity of servo electric cylinder 3, rotating backing plate 4 and support 5 is determined by the quantity of vertical support rod 1;

[0050] Step 2: Connect the standard rods to form a vertical support rod 1 and a horizontal support rod 2, install a support 5 at the bottom of the vertical support rod 1, install a servo electric cylinder 3 on the top, and fix it on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com