Household phase-change heating device

A heating device and phase change technology, applied in household heating, household appliances, household heating, etc., can solve problems such as low energy utilization, uneven heating, noise pollution, etc., to avoid local high temperature problems and improve energy utilization. High and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

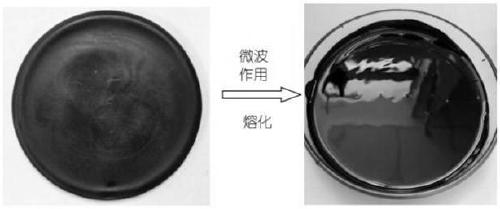

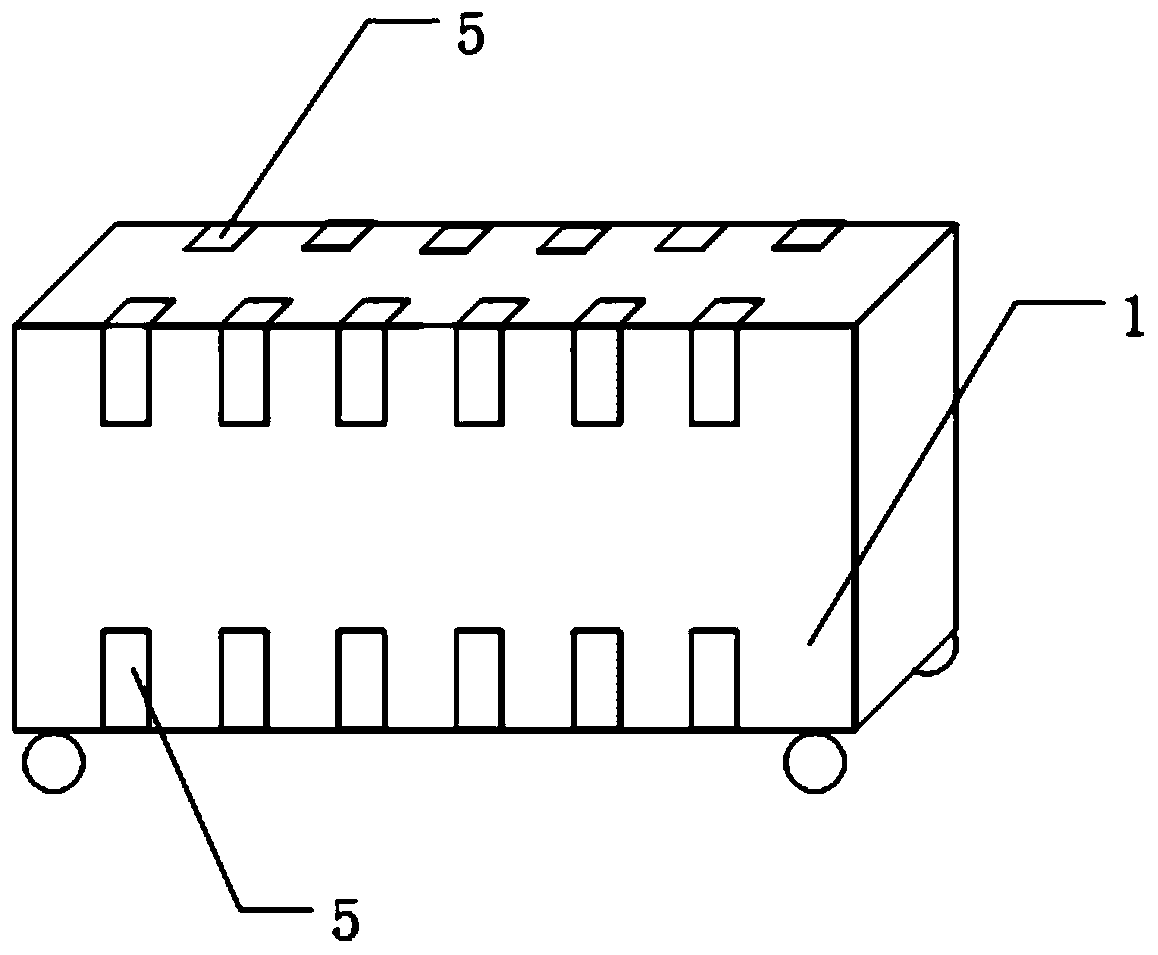

[0054] A new household phase change heater provided in this embodiment includes a housing, a waveguide, a microwave automatic generator, and a wave absorbing heat storage plate. The wave absorbing heat storage plate is filled with a composite phase change material. Wherein, the composite phase change material is a paraffin / graphene composite material, and its preparation steps are as follows:

[0055] 1. Take 30g of paraffin wax, pulverize it, and heat it at 100°C to melt it;

[0056] 2 Weigh 0.15 g of single-layer graphene, and add it into the melted paraffin while stirring;

[0057] 3 Stir fully on the stirrer for 10 minutes, so that the graphene is evenly dispersed in the paraffin, and a composite phase change material is obtained.

Embodiment 2

[0059] A new household phase change heater provided in this embodiment includes a housing, a waveguide, a microwave automatic generator, and a wave absorbing heat storage plate. The wave absorbing heat storage plate is filled with a composite phase change material. Wherein, the composite phase change material is a paraffin / graphene composite material, and its preparation steps are as follows:

[0060] 1. Take 30g of paraffin wax, pulverize it, and heat it at 110°C to melt it;

[0061] 2 Weigh 0.225g of single-layer graphene, and add it into the melted paraffin while stirring;

[0062] 3 Stir fully on the stirrer for 12 minutes, so that the graphene is evenly dispersed in the paraffin, and a composite phase change material is obtained.

Embodiment 3

[0064] A new household phase change heater provided in this embodiment includes a housing, a waveguide, a microwave automatic generator, and a wave absorbing heat storage plate. The wave absorbing heat storage plate is filled with a composite phase change material. Wherein, the composite phase change material is a paraffin / graphene composite material, and its preparation steps are as follows:

[0065] 1. Take 30g of paraffin wax, pulverize it, and heat it at 120°C to melt it;

[0066] 2 Weigh 0.3g of single-layer graphene, and add it into the melted paraffin while stirring;

[0067] 3 Stir fully on the stirrer for 15 minutes, so that the graphene is uniformly dispersed in the paraffin, and a composite phase change material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com