MEMS micromirror scanning light path system

A technology of optical path system and micromirror, which is applied in the field of scanning micromirror, can solve the problems of small picture, small scanning angle of MEMS imaging, and large space occupied by projection, and achieve the effect of small power, large scanning angle, and no need for heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose, the specific implementation, structural features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

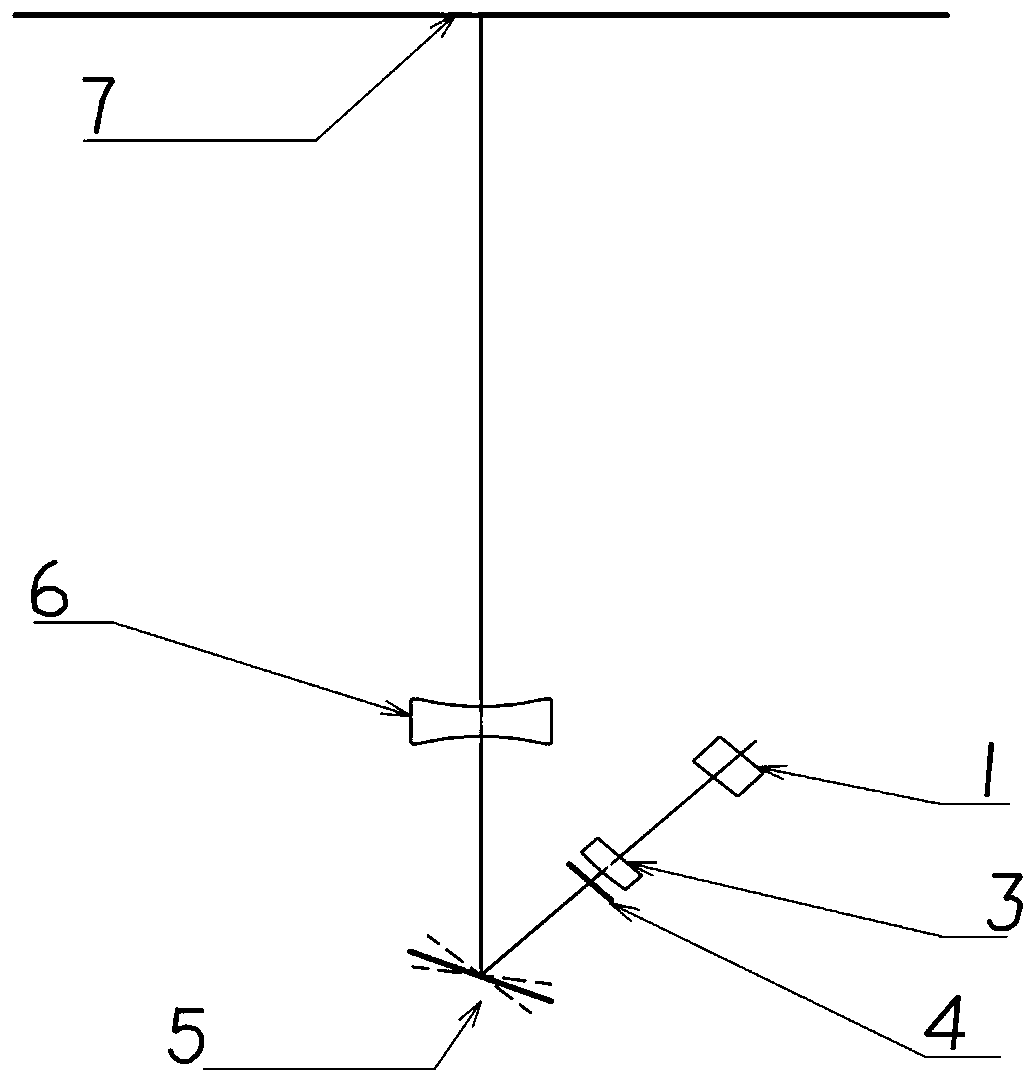

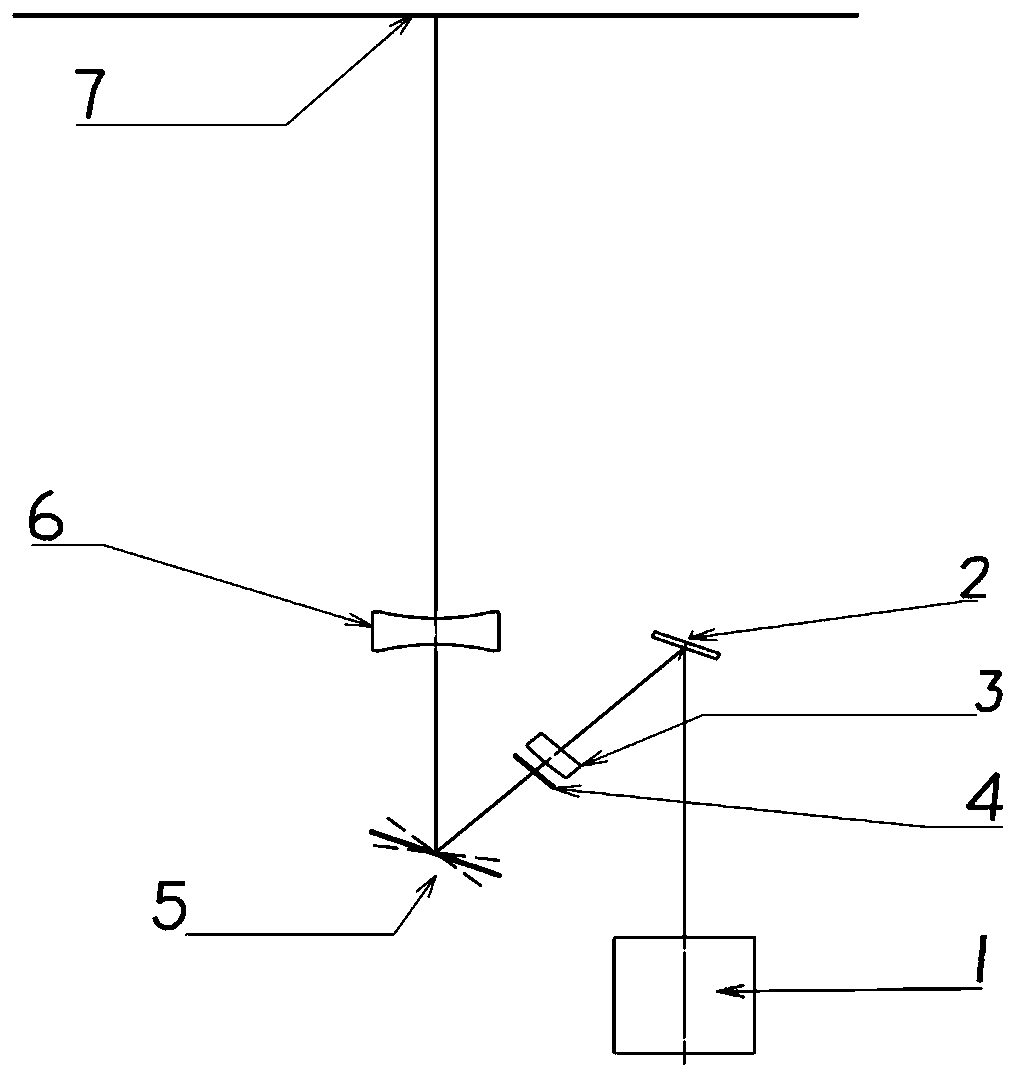

[0016] A MEMS micromirror scanning optical path system, comprising: a laser 1, a compensation lens 3, a small aperture 4, a MEMS micromirror 5, a beam expander lens 6, and an imaging screen 7; the light generated by the laser 1 passes through the compensation lens 3, the light The small hole 4, the MEMS micromirror 5 and the beam expander lens 6 are displayed on the imaging screen.

[0017] An optical path can be communicated between the laser 1 and the compensation lens 3 through the entrance reflection mirror 2 .

[0018] The aperture of the diaphragm aperture 4 matches the size of the scanning lens of the MEMS micromirror 5 to avoid diffraction fringes from occu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com