Battery pack and thermal management method thereof

A technology for battery thermal management and battery packs, which is applied to secondary batteries, battery pack components, circuits, etc., can solve problems affecting the heating or heat preservation of battery packs, and achieve the effects of easy implementation, simple structure, and lightweight materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

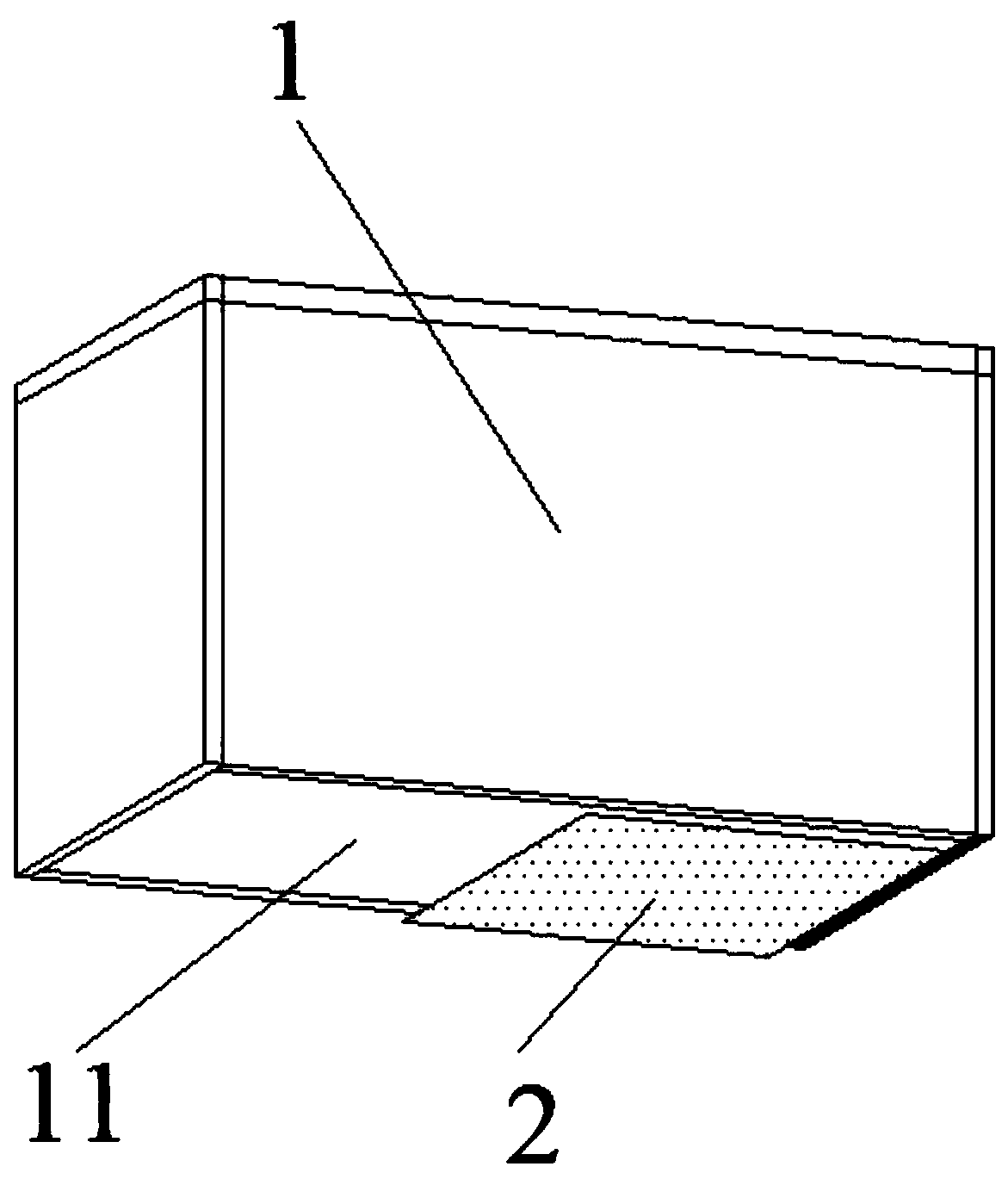

[0021] like figure 1 As shown, the present embodiment provides a battery pack, including a battery box 1 and a heat insulating film 2, at least one side of the battery box 1 is provided with a heat dissipation plate 11, and the heat insulating film 2 is placed on one side of the heat dissipation plate 11 in a rollable and unrollable manner. On the other hand, the unrolled thermal insulation film 2 covers the surface of the cooling plate 11, and the winding and unwinding of the thermal insulation film 2 is controlled by the battery thermal management system.

[0022] One side of the heat dissipation plate 11 is provided with a guide rail, and the heat insulating film 2 is unrolled along the guide rail and covered on the surface of the heat dissipation plate 11 of the battery box. The thermal insulation film 2 is connected with a motor, and is rolled and unrolled under the action of the traction force of the motor. Wherein, the unrolled length of the heat insulating film 2 is g...

Embodiment 2

[0024] This embodiment provides a thermal management method for a battery pack, setting the external environment temperature as T ai , the real-time temperature of the battery pack is T i , according to the ambient temperature T ai and the real-time temperature T of the battery pack i Adjust the unwinding or rewinding of the thermal insulation film 2.

[0025] When 20℃≤T i When ≤35℃, the insulation film 2 is unwound. The battery pack is insulated from the outside world.

[0026] When T i ai i , the insulation film 2 is unwound. The battery pack is insulated from the outside world.

[0027] When T i ai > T i , the thermal insulation film 2 is wound up. The battery pack is free to heat exchange with the outside world.

[0028] When T i >35℃, and T ai i , the thermal insulation film 2 is wound up. The battery pack is free to heat exchange with the outside world.

[0029] When T i >35℃, and T ai > T i , the insulation film 2 is unwound. The battery pack is insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com