Lithium battery pole piece laminating device

A stacking device and lithium battery technology, which is applied in secondary batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of changing diaphragm pressing force and low film coating efficiency, achieving constant pressing force and increasing placement speed , the effect of convenient change of direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

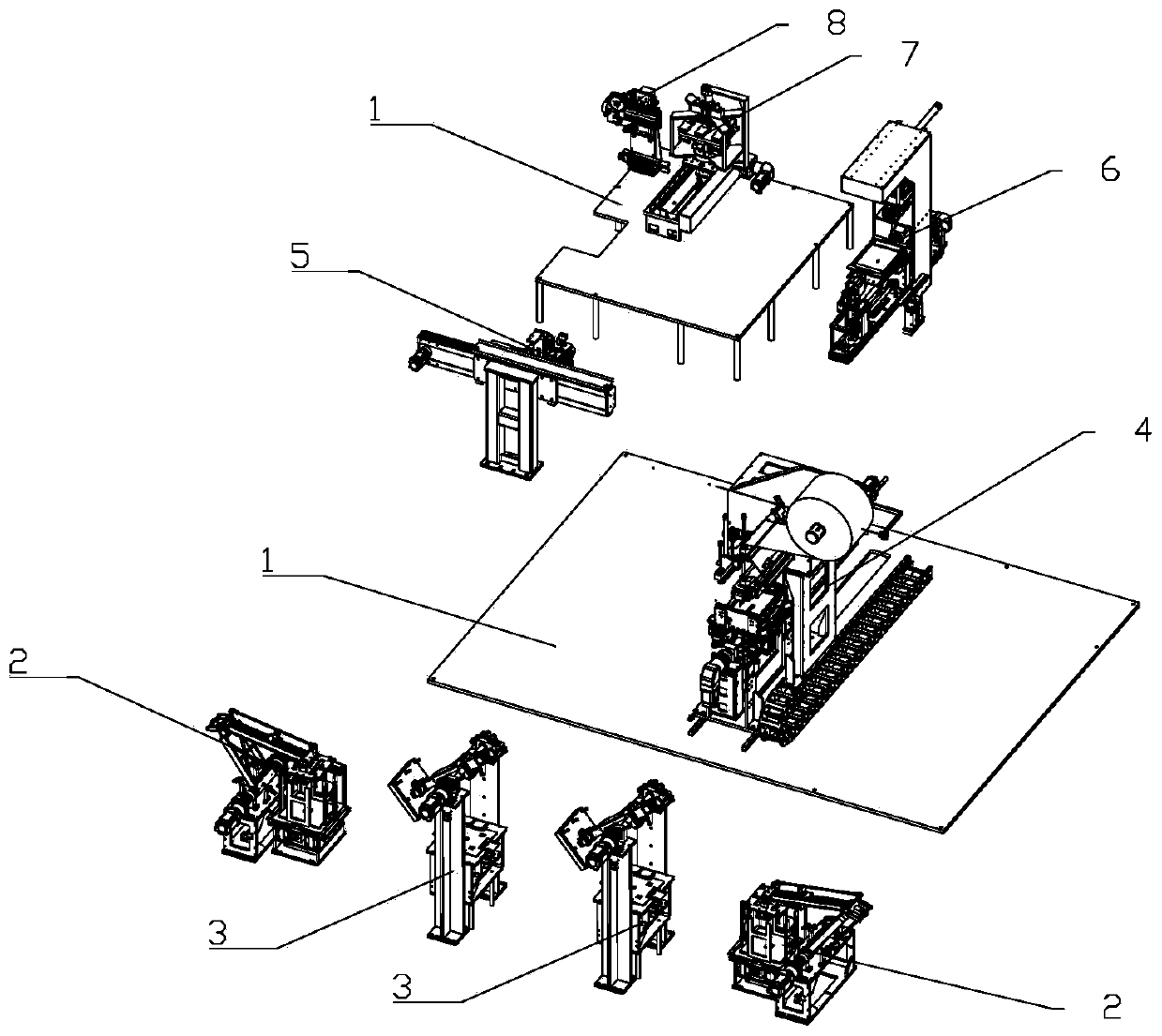

[0026] Such as figure 1 As shown, a lithium battery stacking machine includes a frame 1 and a turning plate feeding device 2 installed on the frame 1, a positioning shifting device 3, a stacking device 4, a handling device 5, a rolling device 6, Pressure-holding device 7 and unloading device 8; described turning plate feeding device 2 and positioning material shifting device 3 are all provided with two groups, and positioning material shifting device 3 is positioned at the both sides of stacking device 4, and described turning over The plate feeding device 2 is located on the side of the positioning and shifting device 3; the rolling device 6 is located on the side of the stacking device 4, and the pressure maintaining device 7 is located on the side of the rolling device 6. The conveying device 5 transitionally connects the stacking device 4 , the rolling device 6 and the pressure holding device 7 ; the unloading device 8 is located on the side of the pressure holding device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com