Steel slag crushing and screening integrated device

A steel slag and integrated technology, which is applied in the field of scrap steel slag recycling and processing equipment, can solve the problems of occupied area, reduced cake pressing efficiency, laborious scrap steel slag, etc., and achieves good processing effect and compact structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

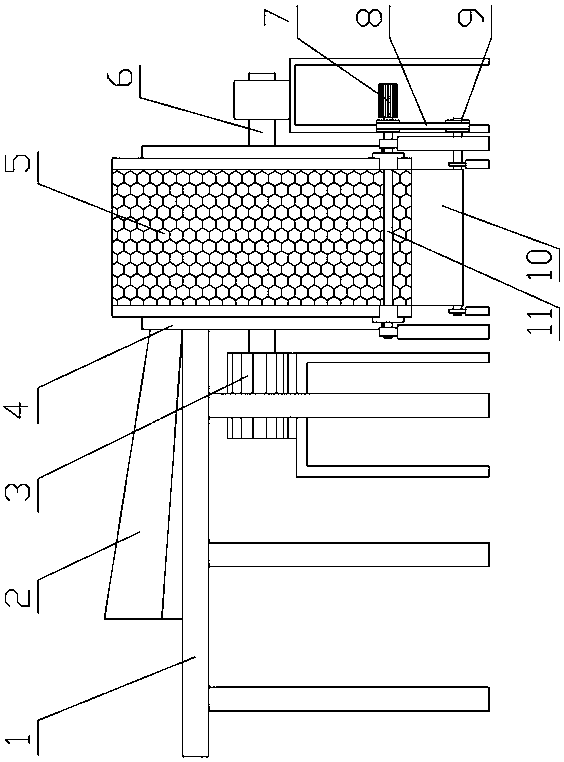

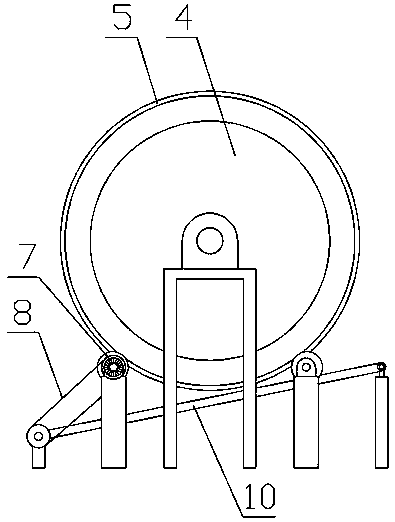

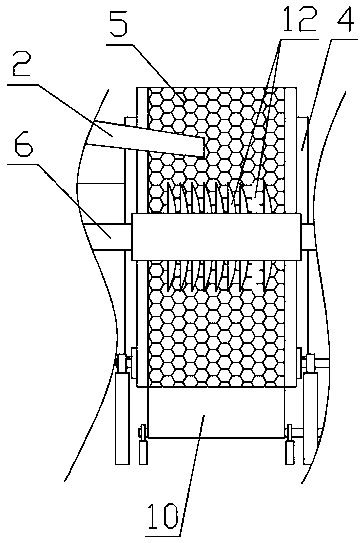

[0013] see Figure 1-Figure 3 , the present invention is a steel slag crushing and screening integrated device, which has a frame 1, a crushing blade rotating shaft 6 is mounted on the frame, a steel slag crushing blade 12 is installed on the crushing blade rotating shaft, and one end of the crushing blade rotating shaft is connected to a crushing drive The motor 3 is connected by transmission; the periphery of the steel slag crushing blade is equipped with a cylindrical screen 5, and the lower part of the cylindrical screen is provided with two sets of screen idlers 11, and the two sets of screen idlers pass through the idler motor. 7. Carry out driving operation, and the rotation of the sieve idler will drive the rotation of the cylindrical sieve; two circular steel slag baffles 4 are installed on both sides of the slag crushing blade on the shaft of the crushing blade, and the steel slag baffles The plate is set on the rotating shaft of the crushing blade and fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com