Novel high-elasticity polyurethane anti-collision buffer block for sea port

A buffer block, polyurethane technology, applied in the field of polyurethane, can solve the problems of the waste tires are not beautiful enough, the size of the waste tires cannot be customized, and the ship protection is not in place, so as to reduce maintenance costs and use costs, prolong time, and reduce pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

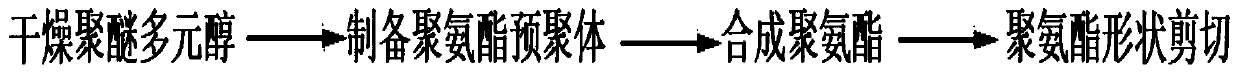

[0027] A new type of high elastic polyurethane seaport and military port anti-collision buffer block preparation process, see figure 1 Process flow chart, proceed as follows:

[0028] Weigh 50 parts of polyether polyols and 75 parts of mixed polyether polyols and put them into a rotary evaporator, rotate them at a temperature of 105° C. for 2.5 hours, and then cool them down to room temperature for later use.

[0029] Pour the dried polyether polyol into the reaction attachment, then add 50 parts of modified MDI to the reaction kettle, mix the polyether polyol and modified MDI evenly, and then react at a temperature of 70°C for 2-3 hours, And take a sample every 15min, calculate the isocyanate content with the titration method, follow up the reaction progress, stop the reaction when the isocyanate content is 11%, obtain the polyurethane prepolymer, prepolymer is defoamed with the rotary evaporator, degassing The foaming temperature is 35°C, and the defoamed polyurethane prepo...

Embodiment 2

[0034] The reaction time was controlled, and the reaction was stopped when the isocyanate content was 8%, and the other preparation processes were the same as in Example 1.

Embodiment 3

[0036] Control the reaction time, stop the reaction when the isocyanate content is 15%, and other preparation processes are the same as in Example 1.

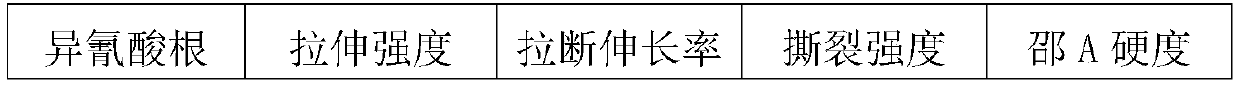

[0037] The polyurethane buffer blocks prepared in the above three examples were tested for mechanical properties, mainly testing the hardness, tensile strength, elongation at break and tear strength of the polyurethane elastomer. The measured data are shown in Table 1.

[0038] Table 1

[0039]

[0040]

[0041] Observing Table 1, the following conclusions can be drawn: the content of isocyanate has an effect on tensile strength, elongation at break, tear strength and Shore A hardness. Tensile strength increases with the increase of isocyanate content; elongation at break decreases with the increase of isocyanate content; tear strength increases with the increase of isocyanate content; The Shore A hardness increases with the increase of isocyanate content.

[0042] The Shore A hardness of the rubber is 86, the hardness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com