Chemical raw material crushing processing reaction system and chemical raw material crushing processing technology

A chemical raw material and reaction system technology, applied in chemical/physical/physical chemical stationary reactors, grain processing, etc., can solve the problem of local crushing operation without chemical raw materials, chemical raw material reaction, slow detection speed, large power loss, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

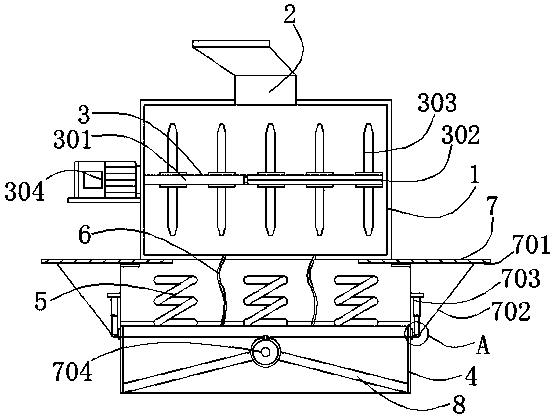

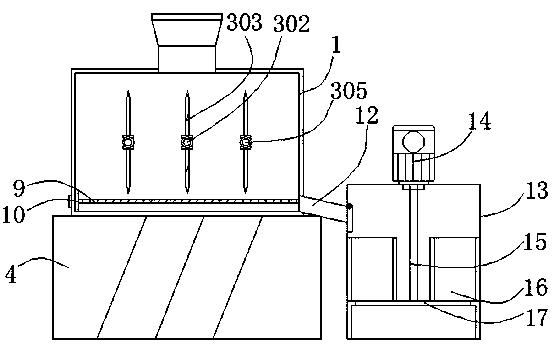

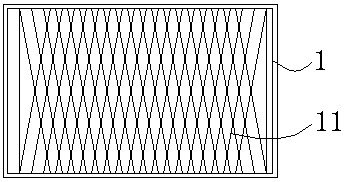

Embodiment 2

[0055] Select the chemical raw materials in advance, and preheat the chemical raw materials that need to be crushed through the heating equipment at a temperature of 80°C, and then put the preheated chemical raw materials into the body 1 through the feeding pipe 2 , start the first motor 304, so that it drives the main shaft 302, the movable shaft 301 and the auxiliary shaft 305 inside the crushing assembly to rotate, and the crushing blade 303 on the outer wall of the main shaft 302, the movable shaft 301 and the crushing blade 303 on the outer wall of the auxiliary shaft 305 are misaligned Rotate to complete the cutting and crushing of chemical raw materials, and the crushed chemical raw materials fall to the elastic fabric 11 due to gravity, and due to accumulation, the elastic fabric 11 is pressed down and abutted against the spring 5, through the spring 5 Rebound, so that the broken chemical raw materials bounce up, and complete the work of mixing and crushing again. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com