A method for improving the quality of continuous casting slabs

A quality improvement and continuous casting slab technology, applied in the field of continuous casting slab quality improvement, can solve the problems of uneven structure of rolled products, fast temperature recovery, cracking at the end of rolled products, etc., to reduce dendrite segregation and improve process Efficiency and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

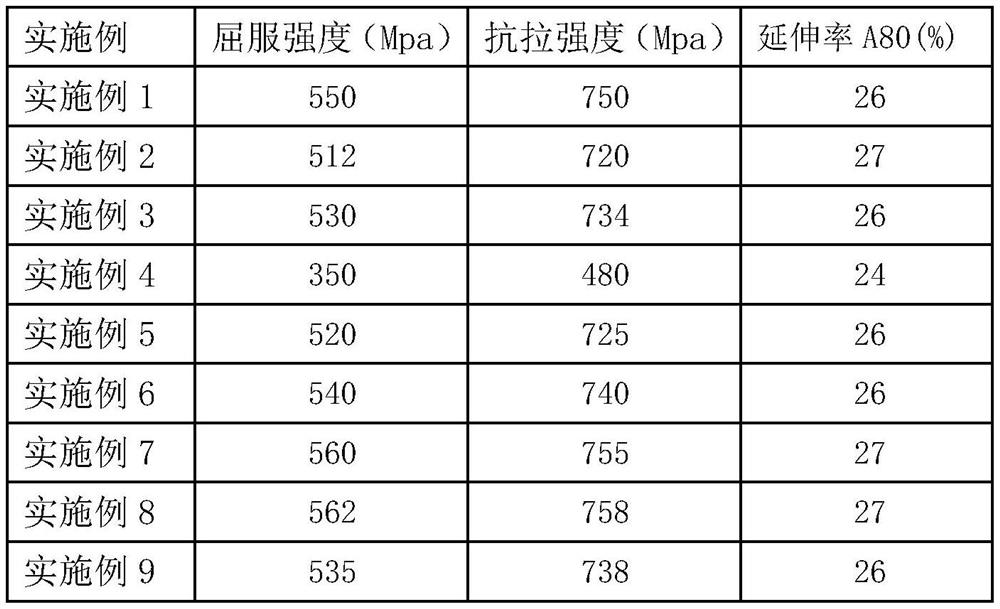

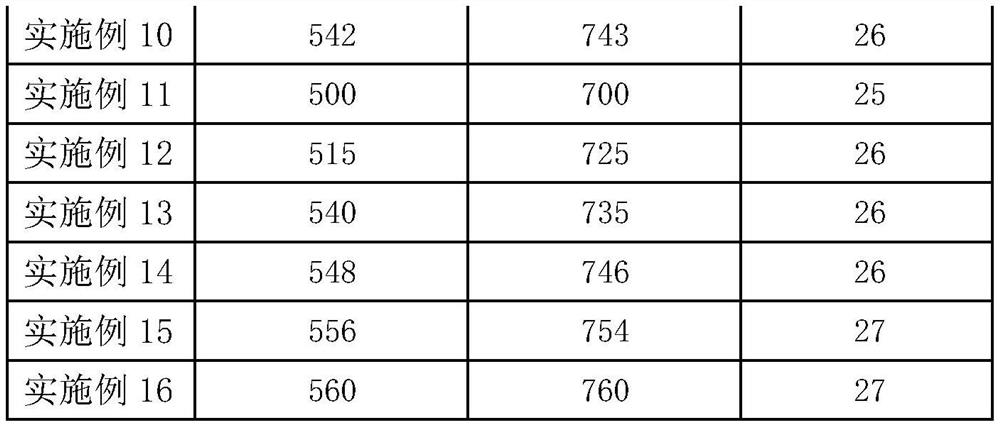

Examples

Embodiment 1

[0017] A method for improving the quality of continuous casting slabs. During the drawing and straightening process of the continuous casting slabs formed after molten steel is cooled and crystallized, the continuous casting is drawn and straightened at a heating rate of 400°C / s by means of current heating in advance. The pulling and straightening rollers of the casting machine are preheated to 600°C. The conveying rollers of the continuous casting machine are preheated, and then the temperature of the conveying rollers is kept at 600°C to transport the slab with a temperature of 900°C after continuous casting to the cutting machine for cutting.

[0018] The cast slab used in this example is a bloom with a size of 325 mm×280 mm obtained after continuous casting, and its chemical composition is shown in Table 1 below.

[0019] Table 1 Chemical composition of billet

[0020] Element C Si mn Cr P S Content (wt%) 0.6 0.20 7.5 1.5 0.01 0.01

[0021]...

Embodiment 2~3

[0023] Embodiments 2 to 3 provide a method for improving the quality of continuous casting slabs. Compared with Example 1, the difference is that the chemical composition of the slab obtained after continuous casting is changed. Except for the above differences, other operations are the same , which will not be repeated here, and the specific condition parameters are shown in the table below.

[0024] Example C Si mn Cr P S Example 2 0.2 0.35 9 1.65 0.025 0.025 Example 3 1.05 0.15 0.25 1.4 0.015 0.015

[0025] After testing, the central porosity and central segregation of the continuous casting slab prepared in Example 2 are all controlled below grade 1.5, the ratio of evaluation grade ≤ grade 1.0 reaches 98.1%, and the elongation A80 is 27%.

Embodiment 3

[0026] The central porosity and central segregation of the continuous casting slab obtained in Example 3 are all controlled below grade 1.5, the ratio of evaluation grade ≤ grade 1.0 reaches 98.3%, and the elongation A80 is 26%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com