Floor tile cutting device and cutting method

A cutting device, a technology for floor tiles, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of low cutting precision, inconvenient operation, low cutting efficiency, etc., and achieve high cutting precision, simple and convenient use, and improved The effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

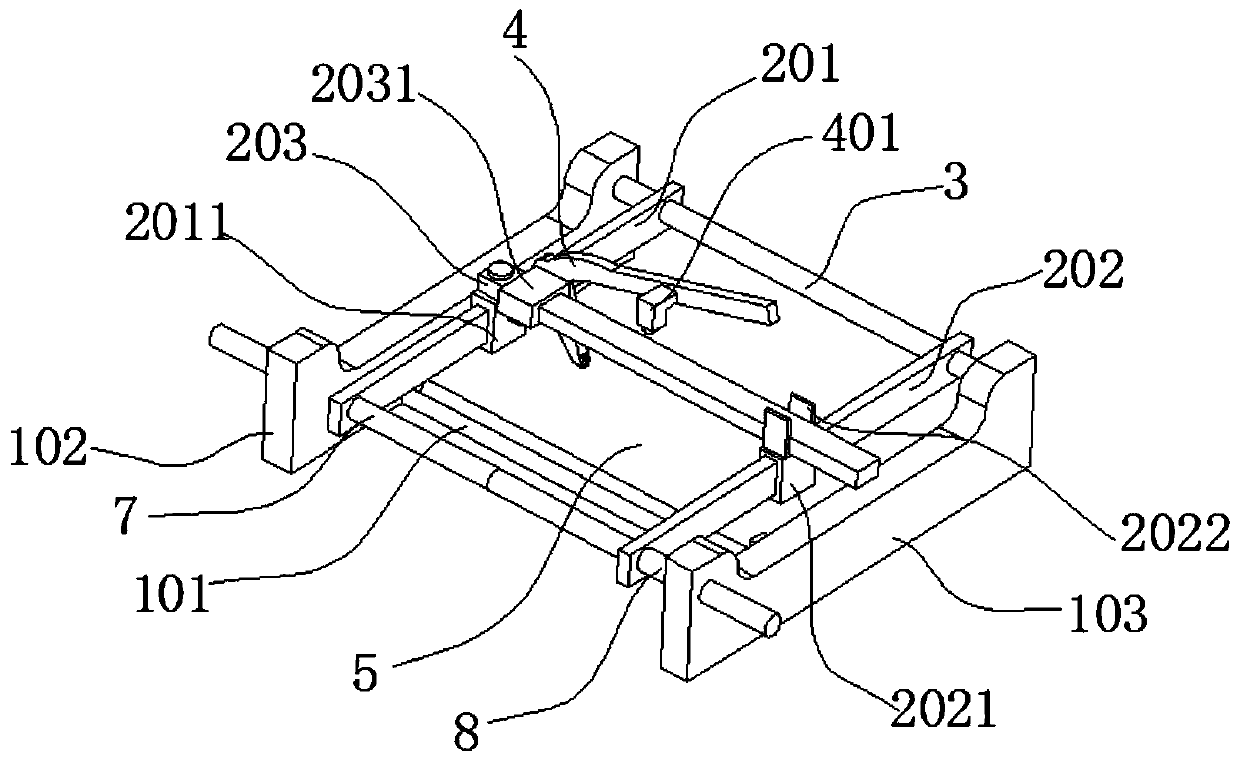

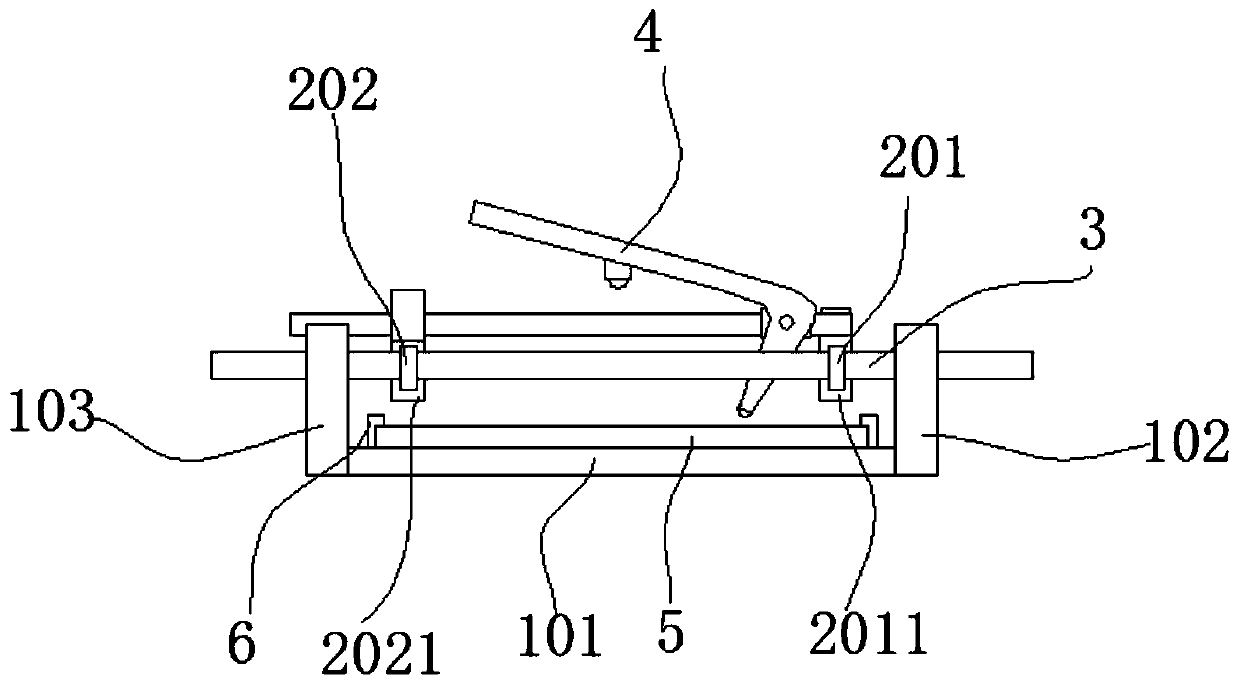

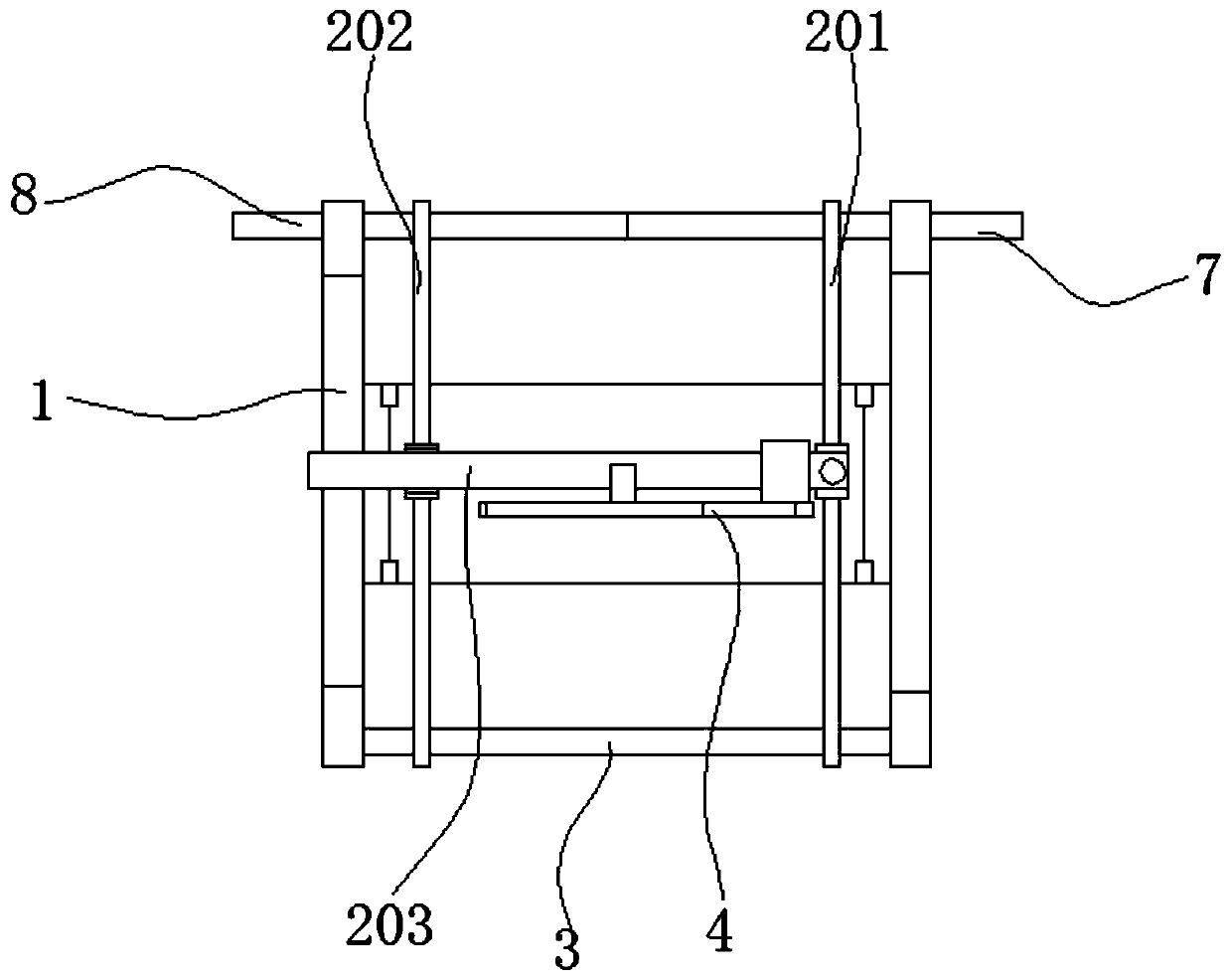

[0045] A floor tile cutting device, comprising a support base 1, an adjustment mechanism 2 and a cutting mechanism 4, the support base 1 includes a base 101, a right bracket 102 and a left bracket 103; the right bracket 102 and the left bracket 103 are connected to the base 101 opposite ends; the cutting mechanism 4 is located between the right bracket 102 and the left bracket 103; the adjustment mechanism 2 includes a second rail 202 and a third rail 203; one end of the third rail 203 is hinged On the right bracket 102, the other end can rotate around the hinge point at the level of the third track 203; the cutting mechanism 4 is slidably connected to the third track 203; the second track 202 is used to fix the second track 203 The movable ends of the three rails 203; the second rail 202 can move in the space between the right bracket 102 and the left bracket 103.

[0046] Specifically, a guide rod 3 is connected between the right bracket 102 and the left bracket 103 ; the se...

Embodiment 2

[0053] With embodiment 1, difference is: as Figure 1 to Figure 3 , Figure 5 and Figure 6 As shown, the adjustment mechanism 2 also includes a first track 201; the first track 201 is arranged parallel to the second track 202; the first track 201 is slidably connected to the guide rod 3, and the first track 201 is The hinge ends of the three rails 203 are hinged on the first rail 201 .

[0054] Specifically, the first rail 201 is slidably connected with the first slider 2011 ; the hinge end of the third rail 203 is hinged on the upper surface of the first slider 2011 .

[0055] In this embodiment, the third rail 203 is hinged on the first slider 2011 that is slidably connected to the first rail 201, so that the third rail 203 can be rotated at any angle (less than 90°), and the second rail 202 can The movable end of the third rail 203 is fixed, so that the cutting mechanism 4 can perform oblique cutting at any angle along the third rail 203 . Of course, there is damping b...

Embodiment 3

[0057] A kind of floor tile cutting method, use the floor tile cutting device described in embodiment 2, it is specifically described below:

[0058] A kind of floor tile cutting method, its specific steps are:

[0059] a. place the floor 5 to be cut on the base 101, and fix the floor 5 with the fixing mechanism 6;

[0060] b. Turn the first screw mandrel 7 to adjust the position of the first track 201, move the first slider 2011, rotate the third track 203 around the hinge point, rotate the second screw mandrel 8, and adjust the position of the second track 202, Move the second slider 2021, rotate the fixed splint 2022, so that the fixed splint 2022 fixes the movable end of the third track 203;

[0061] c. Pull the handle, pull the knife holder to rotate, the cutter 402 cuts into the floor 5, and at the same time, the limit unit 401 is pressed against the third rail 203;

[0062] d. The third slider 2031 moves along the length direction of the third track 203 , and the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com