Automatic glue coating machine for production of packaging box and control method

A packaging box and gluing machine technology, which is applied in the directions of packaging, transportation and packaging, and box production operations, etc. It can solve the problems of incorrect glue brushing position, waste of glue, and high processing quality, so as to achieve accurate glue thickness and position, and improve The effect of automation level and fast gluing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

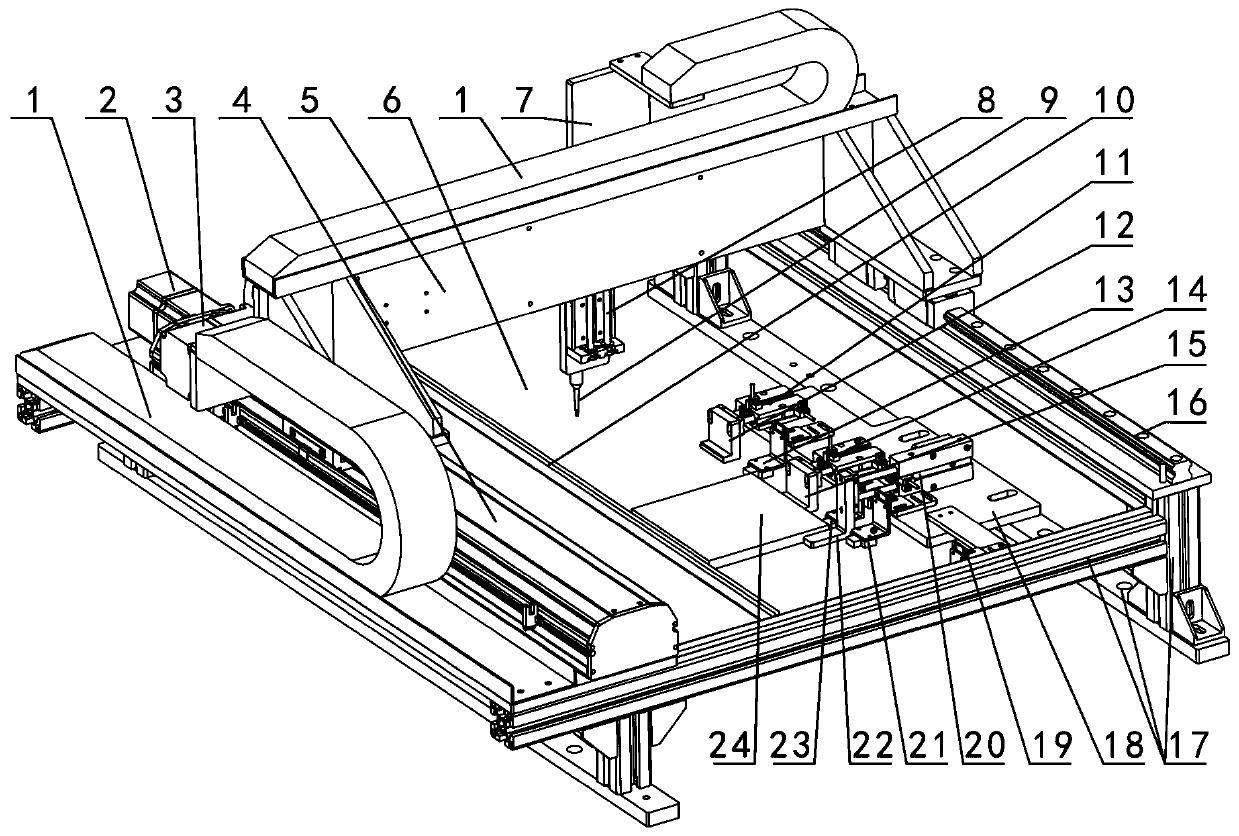

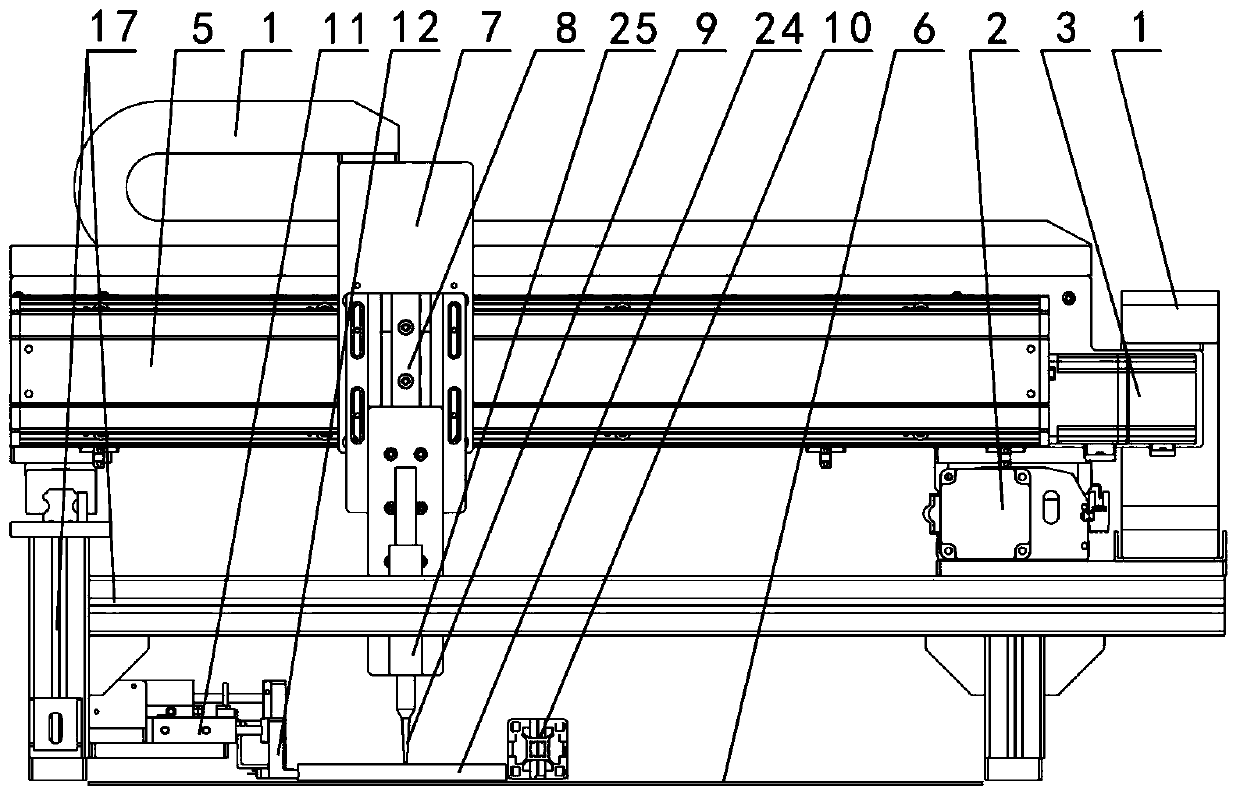

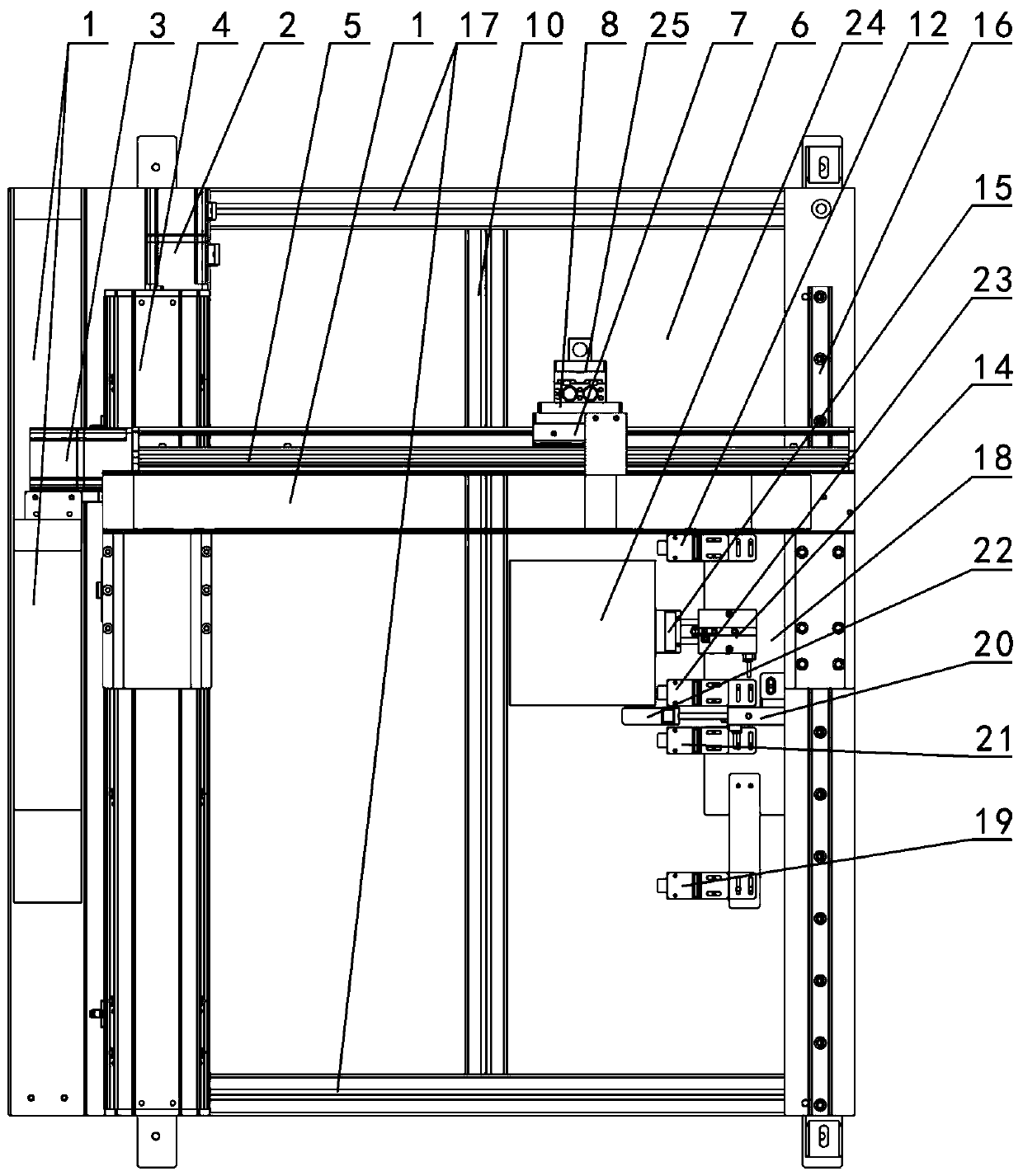

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as figure 1 , figure 2 and image 3 As shown, the automatic gluing machine for packaging box production according to the present invention includes a frame 17, a beam 5, a beam driving motor 2, a gluing cylinder mounting part 7, a mounting part driving motor 3, a gluing cylinder 8, and a gluing solenoid valve 25. Rubber head 9, material distribution cylinder 11, material distribution push plate 12, clamping cylinder 14, clamping push plate 15, material blocking cylinder 20, material blocking rod 22, first proximity sensor 13, second proximity sensor 23. The third proximity sensor 21, the fourth proximity sensor 19 and the controller (not shown in the figure, generally placed in the electric control box, and the electric control box is generally installed on the frame for easy operation), the lower part of the frame 17 Be provided with the conveyer belt 6 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com