Automatic distributing equipment

A kind of equipment and automatic technology, which is applied in the direction of solid materials, packaging, packaging item types, etc., can solve the problems of low work efficiency, high labor intensity of workers, blockage, etc., and achieve the effect of reducing high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

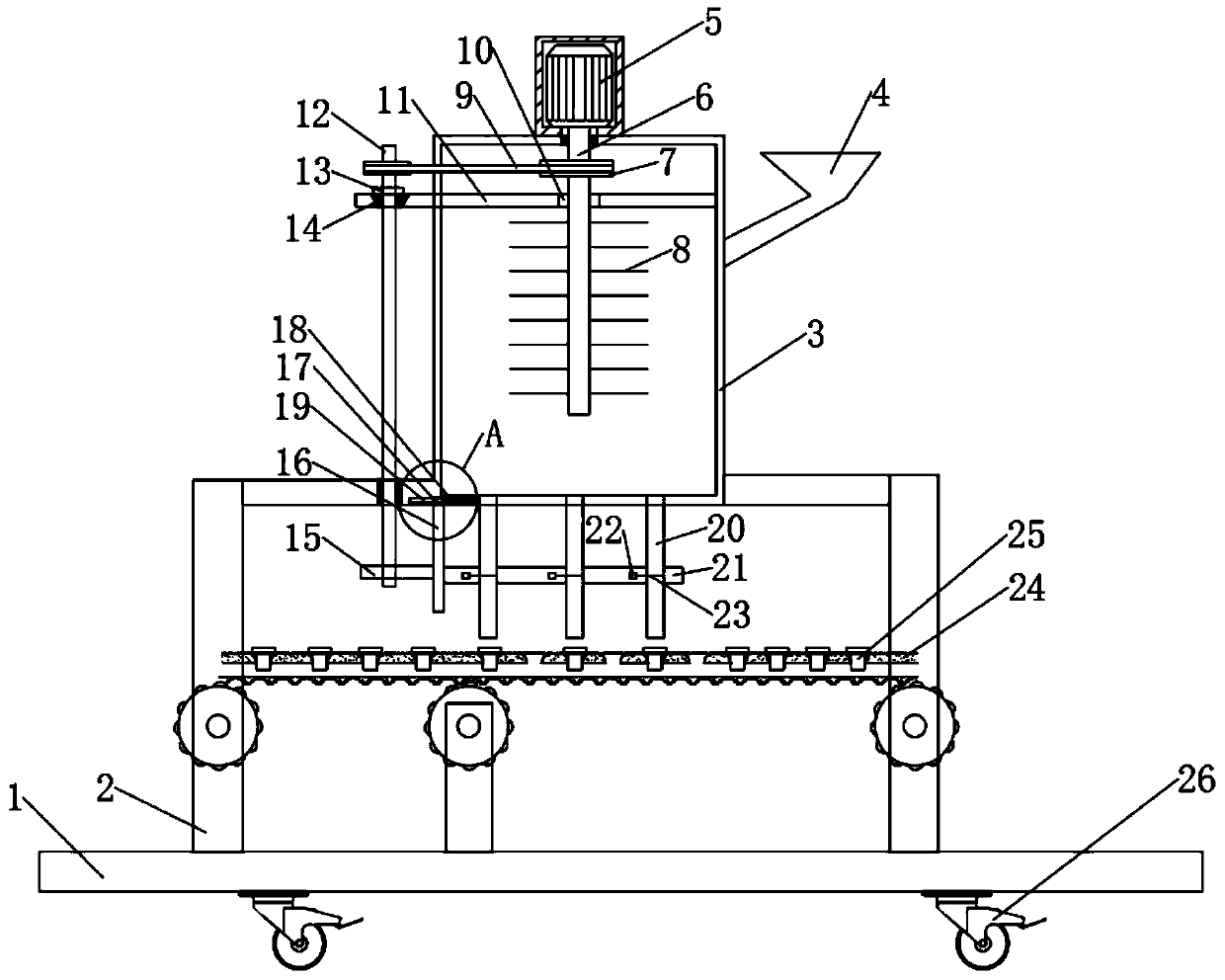

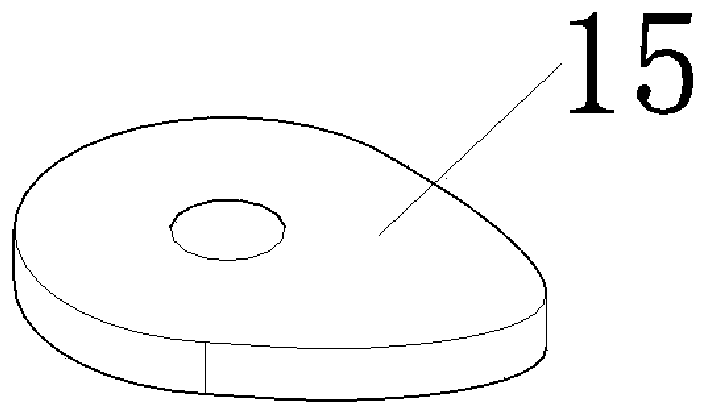

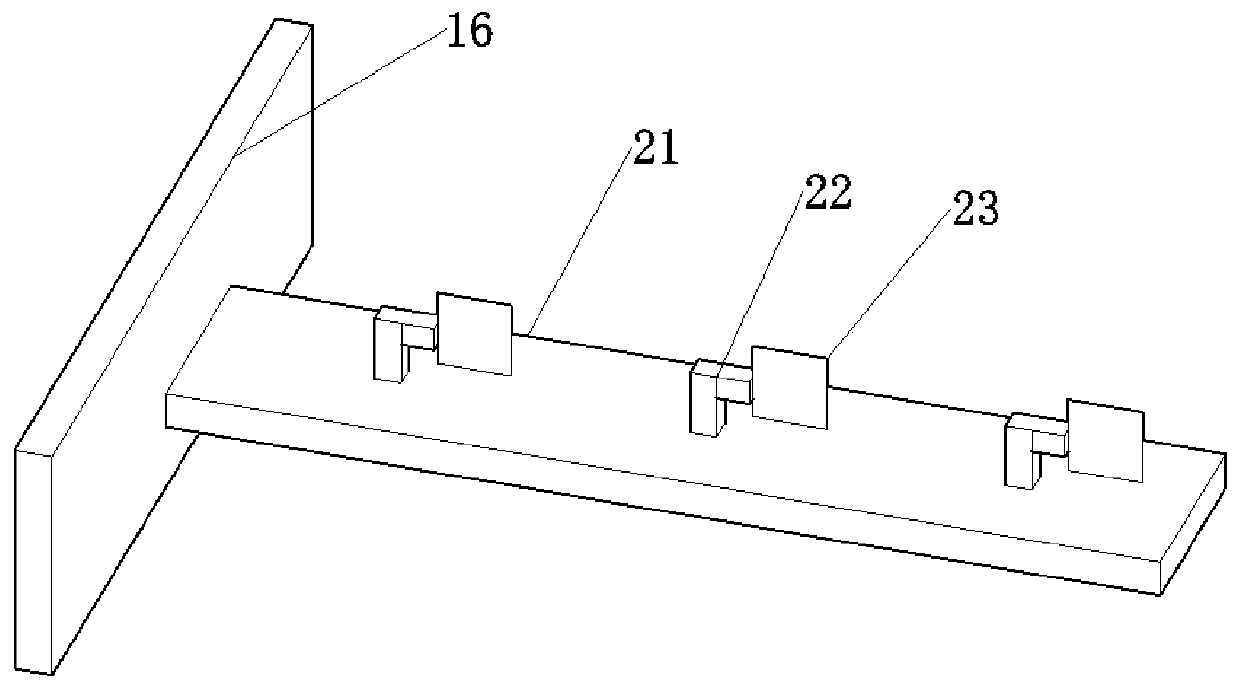

[0026] Such as Figure 1-6 As shown, a kind of automatic distributing equipment comprises base 1, and column 2 is installed on described base 1, and housing 3 is arranged on described column 2, and feed hopper 4 is arranged on described housing 3, and described The top of the housing 3 is provided with a motor 5, the motor 5 is connected to the output shaft 6, the output shaft 6 is evenly provided with a stirring brush 8, the top of the output shaft 6 is equipped with a pulley 7, and the output shaft 6 The driven shaft 12 outside the casing 3 is driven by the pulley 7, the end of the driven shaft 12 is equipped with a cam 15, the cam 15 and the push plate 16 are movably installed, and the bottom of the casing 3 is provided with a chute 19 , the push plate 16 is provided with a slider 17, the slider 17 cooperates with the chute 19, the chute 19 is provided with a return spring 18 on the right side of the slider 17, and the housing 3 The bottom is provided with a blanking tube ...

Embodiment 2

[0042] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0043] A kind of automatic distributing equipment, comprises all parts in embodiment 1, also comprises:

[0044] Further, universal wheels 26 are provided on the base 1 .

[0045] Specifically, the mobility of the device is increased through the setting of universal wheels 26 .

[0046] The working principle of the embodiment of the present invention is:

[0047] Such as Figure 1-6 As shown, the distributing equipment is assembled according to the structural position shown in the figure, the granular material is put into the shell 3 through the feed hopper 4, and the receiving bottle 25 is placed in the receiving groove of the conveyor belt 24.

[0048] Start the motor 5, the granular material falls into the feeding pipe 20 driven by the stirring brush 8, and at the same time the output shaft 6 drives the driven shaft 12 to rotate, thereby driving the cam 15 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com