Intelligent unmanned assembly line for tea packaging

An assembly line and packaging technology, applied in the field of warehousing, can solve the problems of high labor intensity, manual warehousing, manual sorting, etc., and achieve the effect of convenient operation and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

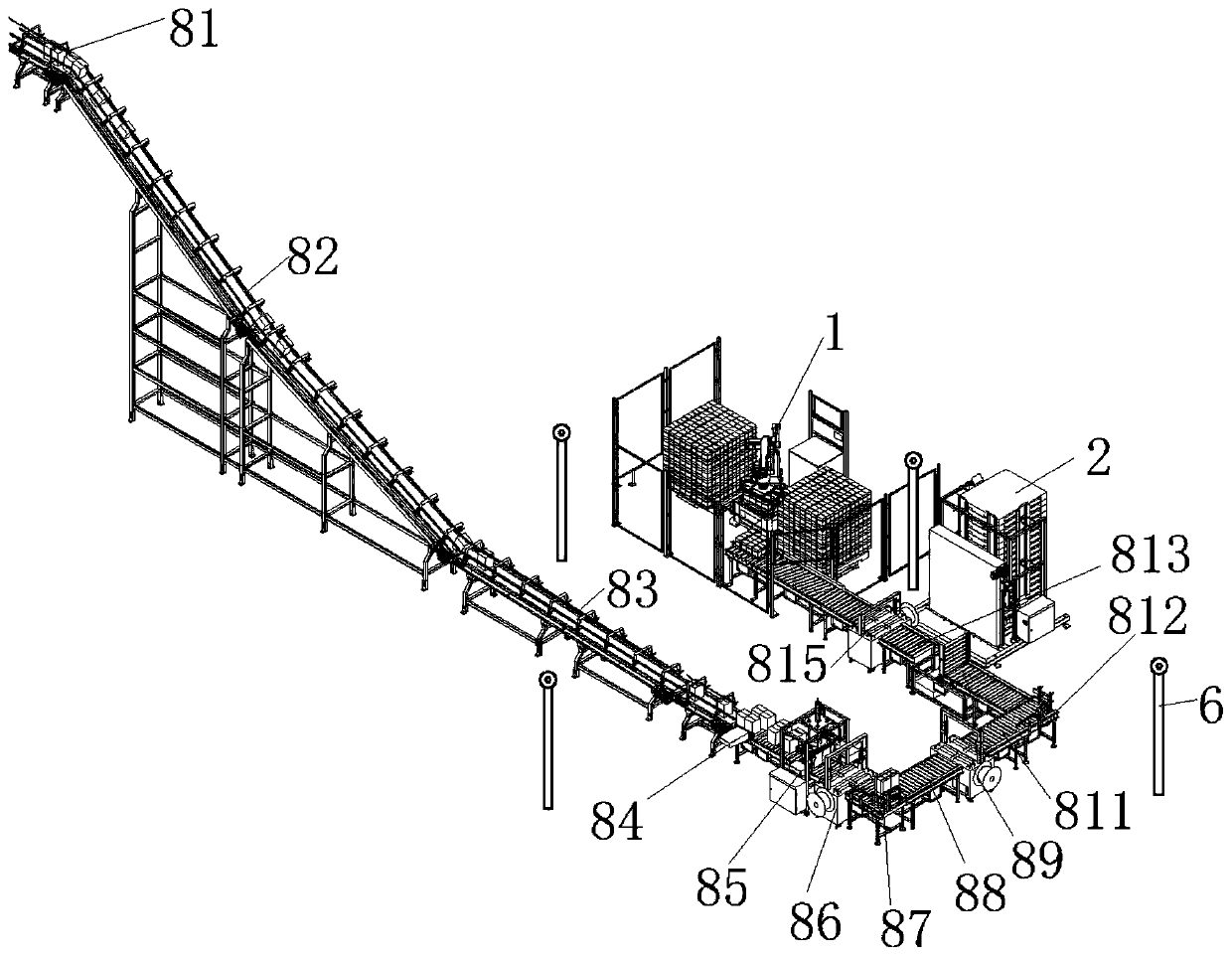

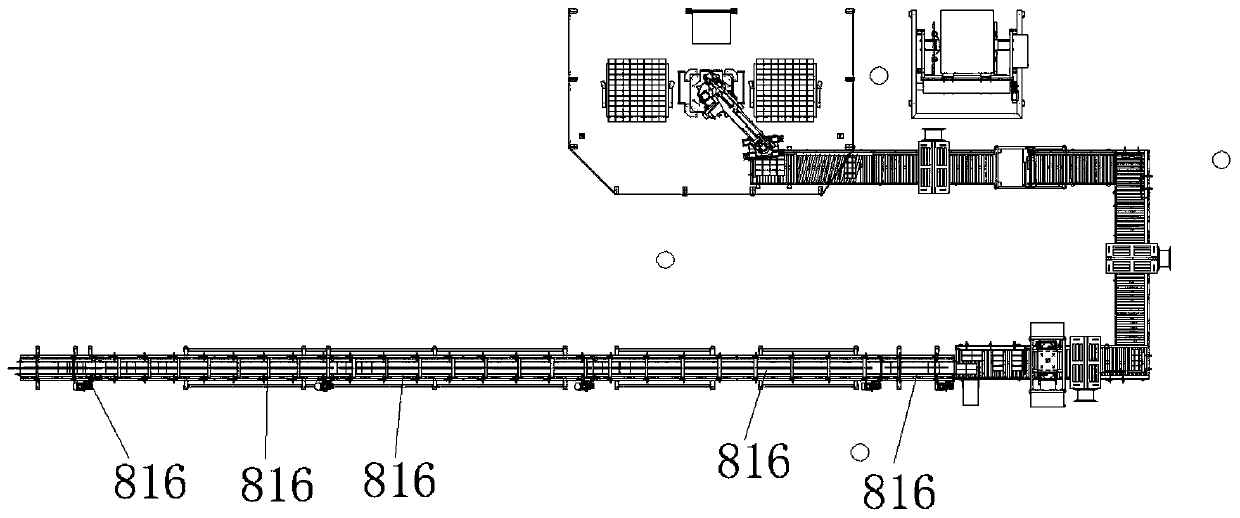

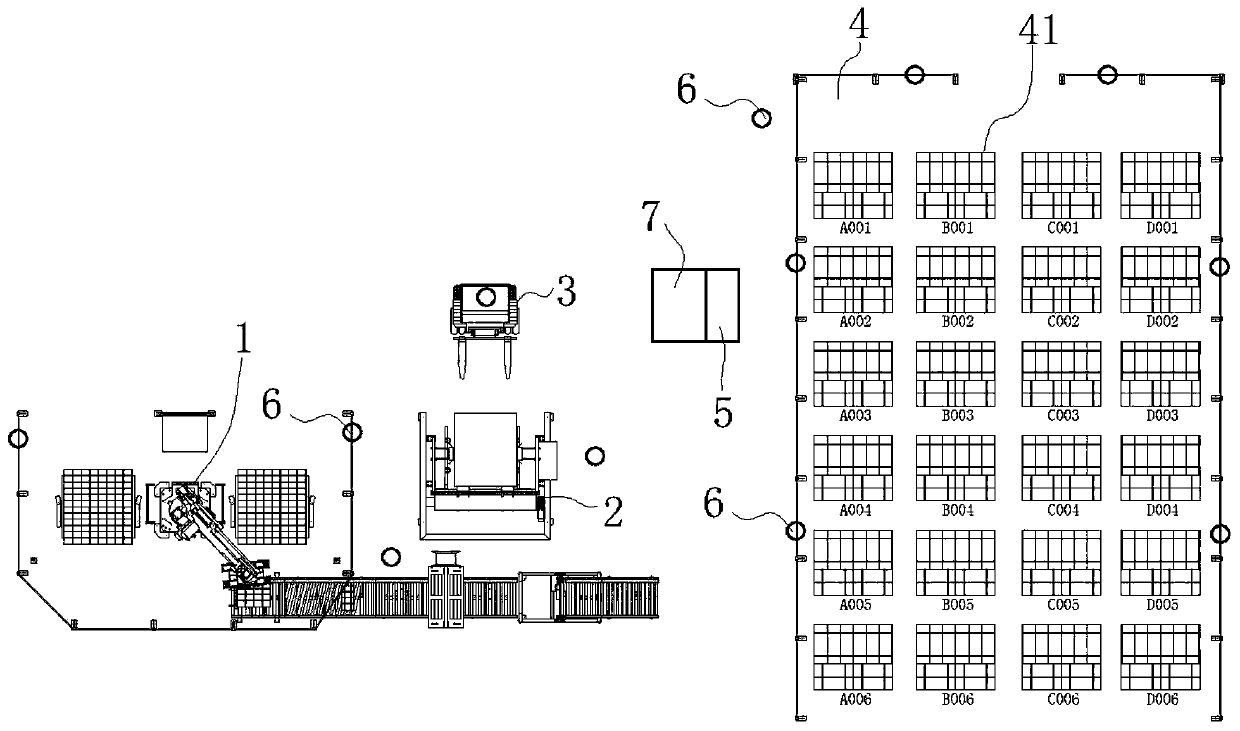

[0059] like Figure 1-24 As shown, the intelligent unmanned assembly line for tea packaging includes a palletizing device 1, a tray device 2, a computer 5, and a conveying assembly line 8; it also includes the existing equipment AGV intelligent forklift 3.

[0060] AGV intelligent forklift 3 refers to a transport vehicle equipped with automatic guidance devices such as electromagnetic or optical, capable of driving along a prescribed guiding path, with safety protection and various transfer functions. AGV intelligent forklift 3 belongs to the category of wheeled mobile robots . A truck that does not require a driver in industrial applications uses a rechargeable battery as its power source. Generally, the computer 5 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com