Modified polypropylene resin and preparation method thereof

A technology of polypropylene resin and polypropylene, which is applied in the field of modified polypropylene resin and its preparation, can solve problems such as high cost and performance that cannot meet market requirements, and achieve the effects of low cost, reduced material cost, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

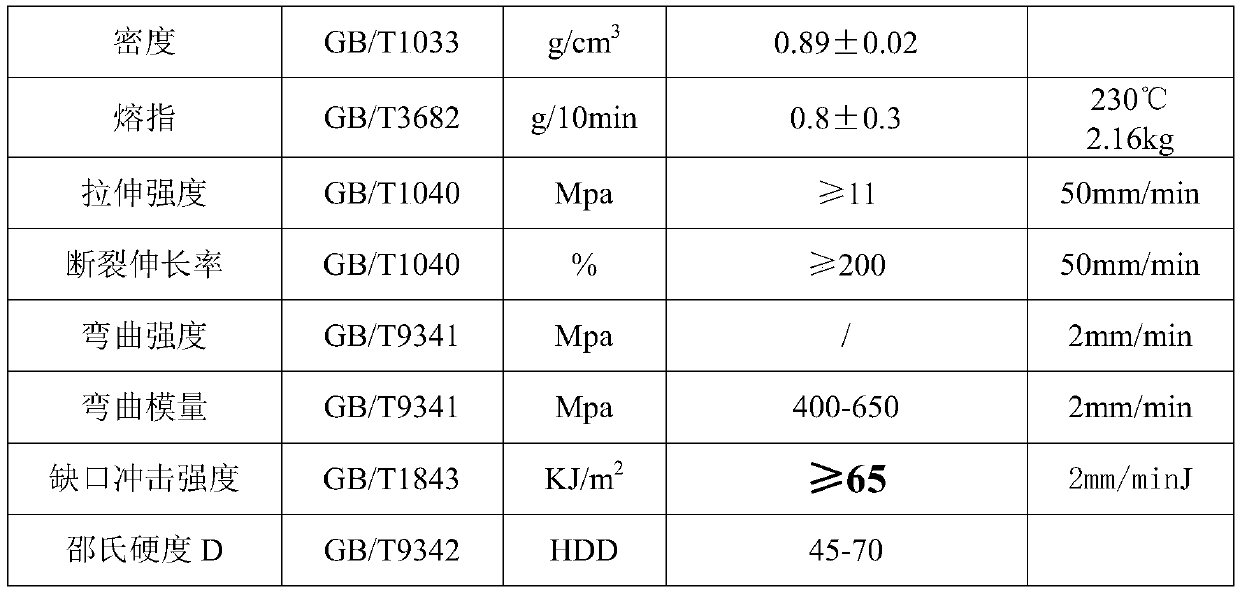

Examples

Embodiment 1

[0014] This embodiment discloses a modified polypropylene resin, and each component includes 50 parts by weight of polypropylene, 10 parts of low-density polyethylene, 10 parts of high-density polyethylene, 20 parts of toughening agent, and 0.1 part of antioxidant. , 0.1 part of anti-aging agent.

[0015] This embodiment also discloses a method for preparing a modified polypropylene resin. First, 50 parts of polypropylene, 10 parts of low-density polyethylene, 10 parts of high-density polyethylene, 20 parts of toughening agent, and the additives 0.1 part of oxidizing agent and 0.1 part of anti-aging agent, fully mix the aforementioned materials through a high-speed mixer, adjust the injection molding machine to 200°C for extrusion, cool with water, and then cut into pellets, and then screen out the pellets of about 0.5 cm. Just bag it.

Embodiment 2

[0017] This embodiment discloses a modified polypropylene resin, each component in parts by weight includes 60 parts of polypropylene, 15 parts of low-density polyethylene, 15 parts of high-density polyethylene, 25 parts of toughening agent, and 0.5 parts of antioxidant. , 0.5 parts of anti-aging agent.

[0018] This embodiment also discloses a method for preparing a modified polypropylene resin. 60 parts of polypropylene, 15 parts of low-density polyethylene, 15 parts of high-density polyethylene, 25 parts of toughening agent, 0.5 part of antioxidant, anti-aging 0.5 part of the agent is fully mixed by a high-speed mixer, the injection molding machine is adjusted to 240 ℃, then the mixed material is extruded, cooled with water, and then cut into granules, and then the granular material of about 0.5 cm is screened out, and finally bagged. .

Embodiment 3

[0020] This embodiment discloses a modified polypropylene resin, and each component includes 55 parts by weight of polypropylene, 12 parts of low-density polyethylene, 12 parts of high-density polyethylene, 18 parts of toughening agent, and 0.3 parts of antioxidant. , 0.3 parts of anti-aging agent.

[0021] This embodiment also discloses a method for preparing modified polypropylene resin. Firstly, 55 parts of polypropylene, 12 parts of low-density polyethylene, 12 parts of high-density polyethylene, 18 parts of toughener, 0.3 part of antioxidant, and The aging agent 0.3 parts is fully mixed by telling the mixer to adjust the injection molding machine to 230°C, and then the mixed material is extruded, cooled by cold water, and then cut into granules, and then the granular material of about 0.5 cm is screened out, and finally bagged. can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com