Composite plugging agent for space station

A plugging agent and space station technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of decreased plugging effect, inability to suspend and disperse nano fillers, and reduced curing strength and other problems, to achieve the effect of simple storage and use, shortened mixing and curing time, and increased curing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

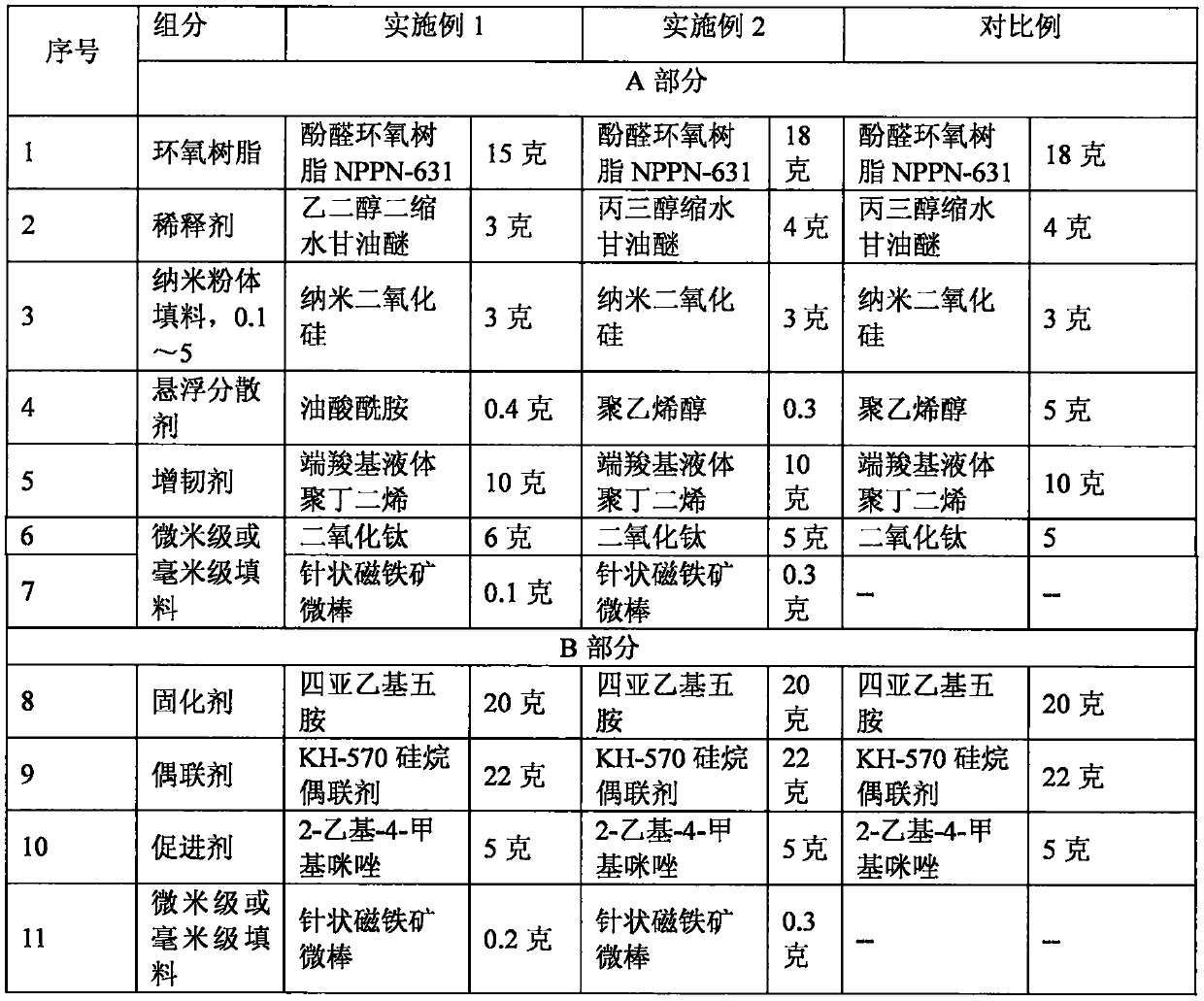

[0039] Mix epoxy dendrites, diluents, nano-powder fillers, suspension dispersants, toughening agents and micron or millimeter fillers uniformly at room temperature, mix them into component A, and store them at room temperature; mix curing agent, coupling agent, accelerator agent, micron-sized filler acicular magnetite microrods, mechanically stirred and mixed at room temperature, and stored at room temperature.

[0040] Formula Table

[0041]

[0042] The A and B components of the above plugging agent were left still at room temperature for 3 months, and the sedimentation and stratification phenomenon occurred in Example 1, Example 2, and the comparative example. The above A and B components were given weak vibrations, and it was found that all The layered settlement phenomenon disappeared in Examples and Comparative Examples.

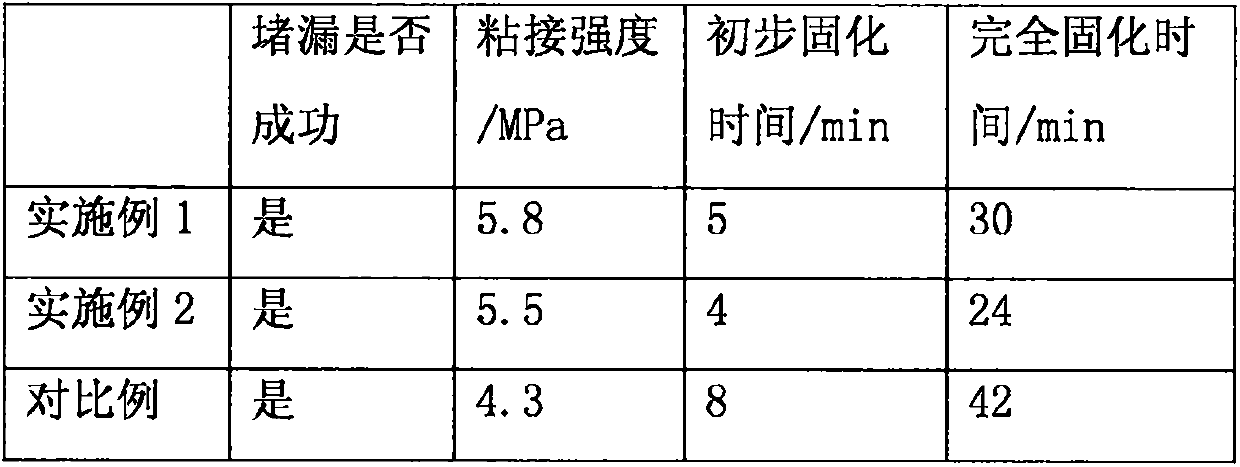

[0043] After mixing components A and B, the plugging performance test is carried out, and the performance is as follows:

[0044]

[0045] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com