Device capable of automatically detecting water content of slag micro powder

A slag micropowder, automatic detection technology, applied in measuring devices, by removing certain components, weighing, instruments, etc., can solve the problems of manpower and material resources, unfavorable long-term development of enterprises, manual detection, etc., to save manpower and material resources, realize The effect of automated detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

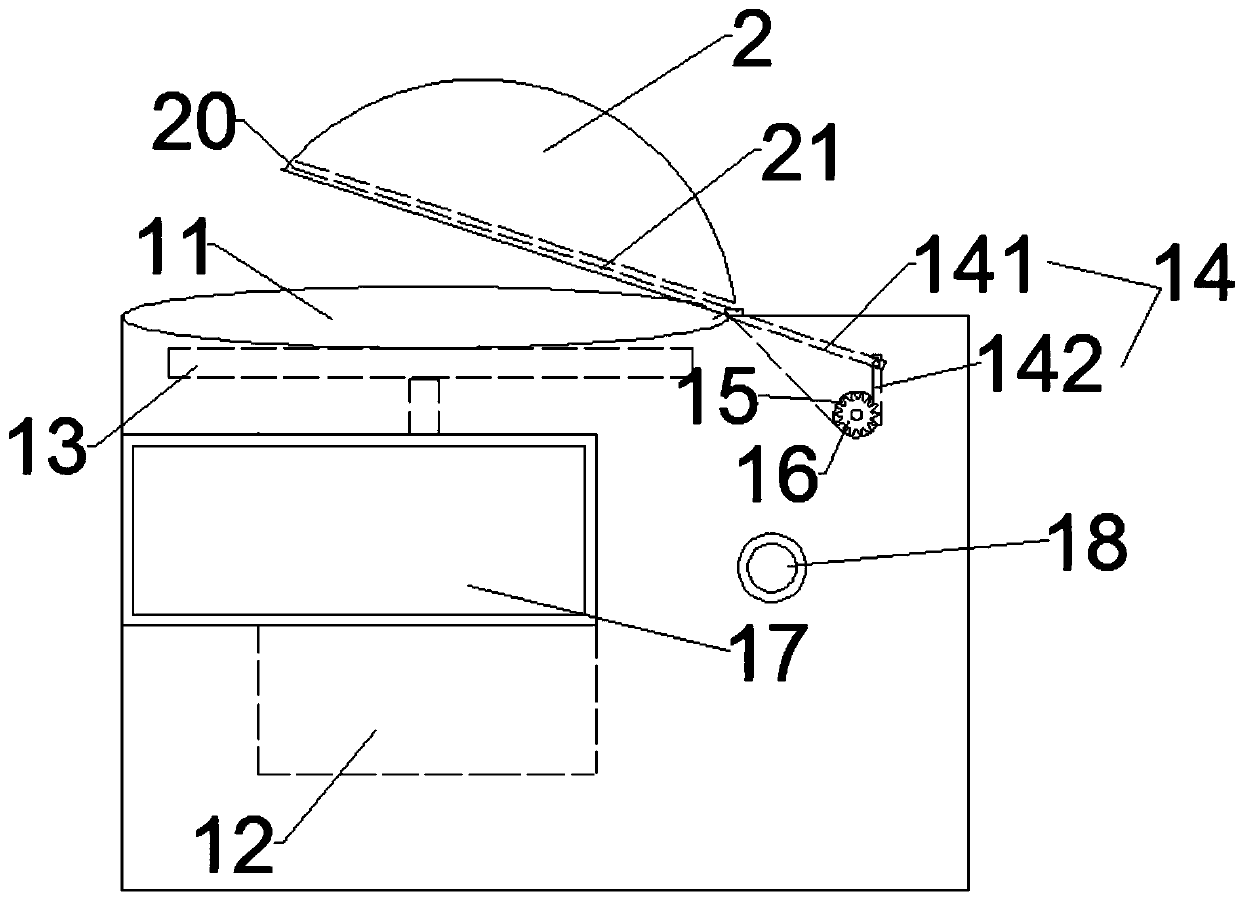

[0018] see figure 1 , a device that can automatically detect the water content of slag powder according to the present invention includes a workbench 1 and a cap 2. A control device 12 is provided in the workbench, a transmission belt (not shown) is provided on the workbench 1, and a circular detection area 11 is arranged on the transmission belt, and the area of the detection area 11 should be smaller than the coverage of the cap 2 A weighing device 13 is provided below the detection area 11, and the weighing device weighs the sample weight in the detection area 11, and the weighing device 13 is connected with the detection area 11 and the control device 12.

[0019] A transmission mechanism 14 is provided inside the workbench 1, and the transmission mechanism 14 includes a first connecting rod 141 and a second connecting rod 142. The first connecting rod 141 is connected to the cap 2. Preferably, the cap 2 is connected to the The first connecting rod 141 is rigidly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com