Sampling method for HY-MK05B dew point detection module

A HY-MK05B, detection module technology, which is used in the preparation, sampling, and measurement devices of test samples, can solve the problems of dew point measurement error, large measurement error of dew point transmitter, affecting sample gas flow, etc., and achieve stable detection. Reliable, extended service life, extended service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

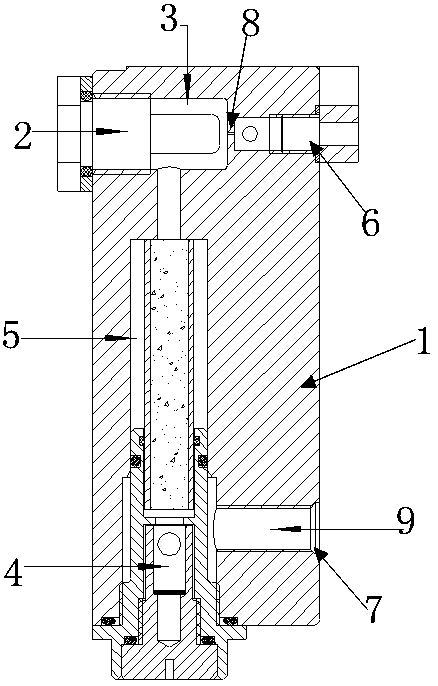

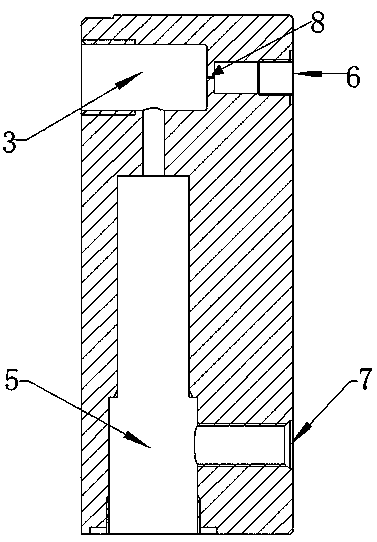

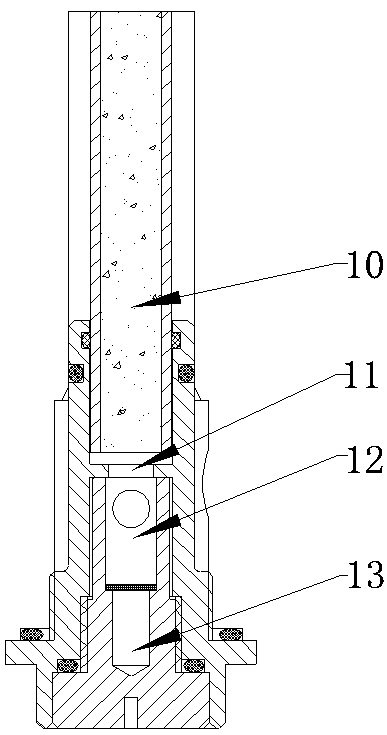

[0036] Embodiment 1: The sampling system is integrally processed with aluminum materials and installed vertically. The lower part is the gas inlet 7 for the sample gas. It is connected with the ferrule joint with the thread of M12*1.25. To ensure its rigidity and long-term reliability, the card sleeve joint adopts φ6 type, which is connected with φ6*1 stainless steel pipe sampling tube, and its pressure bearing capacity can reach more than 35Mpa (the gas pressure limit at the outlet of the compressed air dryer is 1.1Mpa ). The sample gas enters the filter chamber 5 from the lower air inlet 7, and a three-stage filter unit 4 is provided in the filter chamber 5, which can fully filter the oily substances and particulate matter in the sample gas, and the filtered sample gas reaches vertically upwards Measuring chamber 3. One end of the measurement chamber 3 is the installation port of the dew point transmitter 2, and the dew point transmitter 2 is installed horizontally. The ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com