A damage detection method for truck bearings

A technology for damage detection and bearings, applied in the direction of neural learning methods, image data processing, biological neural network models, etc., can solve the problems of low accuracy, long time consumption, low efficiency, etc., to improve efficiency, improve operation quality, and flexibility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

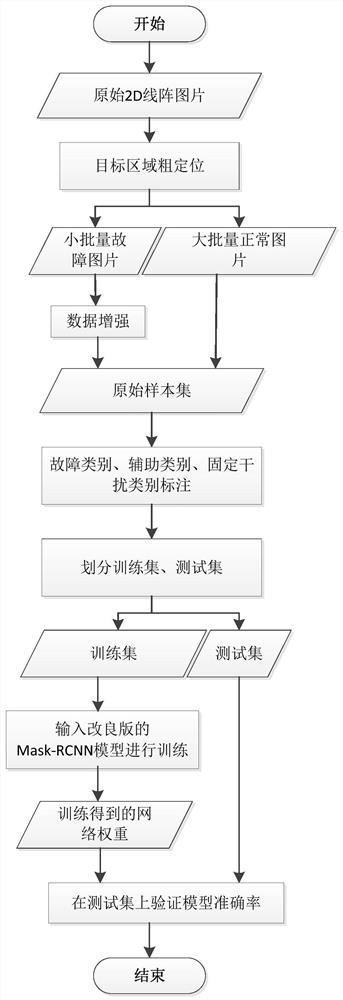

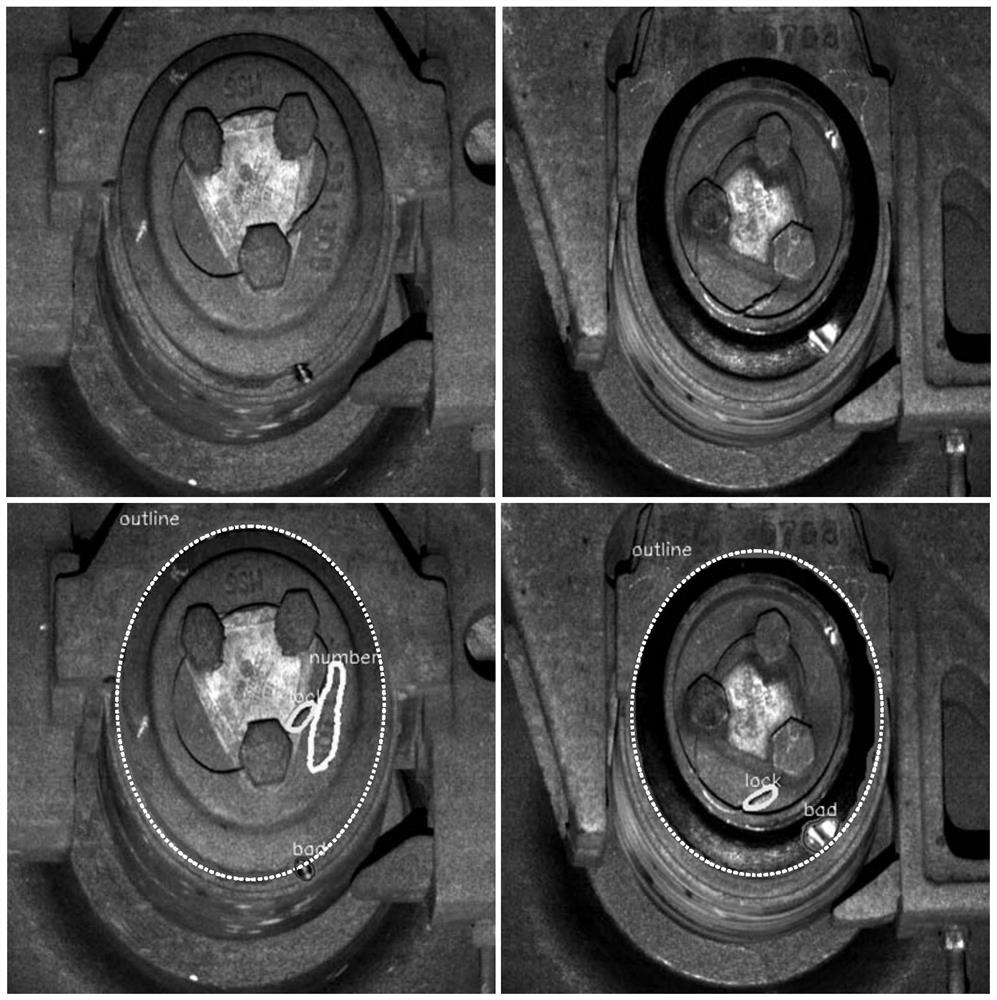

[0038] The implementation of a method for detecting damage to a truck bearing described in this embodiment is divided into two stages: a training stage and an inference stage.

[0039] 1. Training phase, such as figure 1 Shown:

[0040] 1.1. Image Collection

[0041] Use a line-scan camera, that is, a line-scan camera, to collect images, calculate the shooting frequency of the line-scan camera based on the moving speed of the measured object, and take multiple consecutive pictures, and combine the multiple "strip" images taken In this way, seamless splicing can be realized to generate a two-dimensional image with a large field of view and high precision.

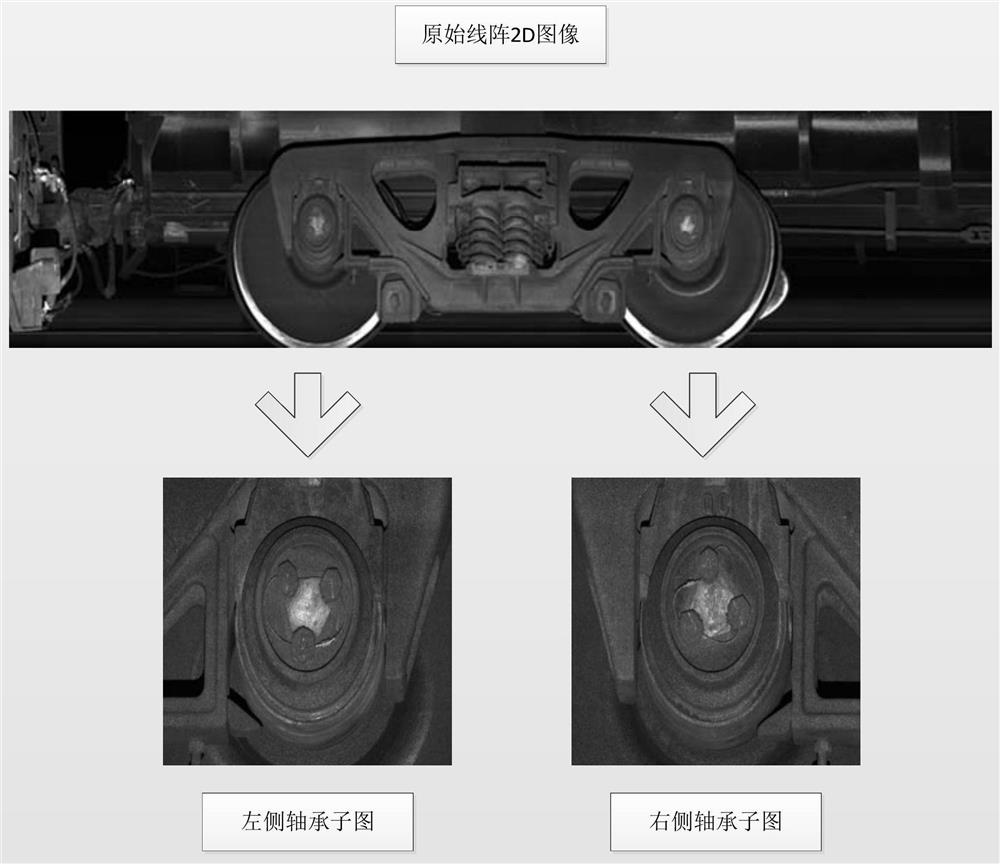

[0042] 1.2. Coarse positioning of the target area

[0043] According to the prior information such as the wheelbase of the truck and the location of the bearing area of the truck, the bearing area of the truck is determined from the two-dimensional image and the image of the bearing area of the truck is extracted, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com