Waste gas treatment device

A waste gas treatment device and concentration device technology, which is applied in the direction of combined devices, combustion methods, lighting and heating equipment, etc., can solve the problems of easy clogging of zeolite runners, time-consuming and labor-intensive, and many harmful substances, and avoid frequent replacement of filter materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

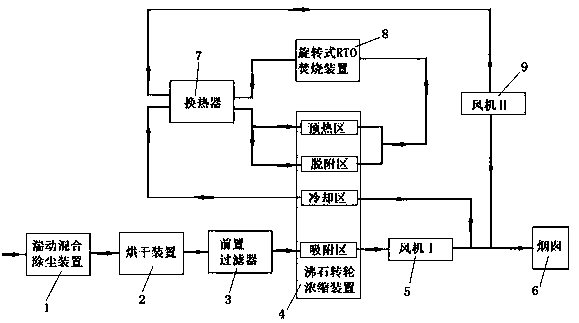

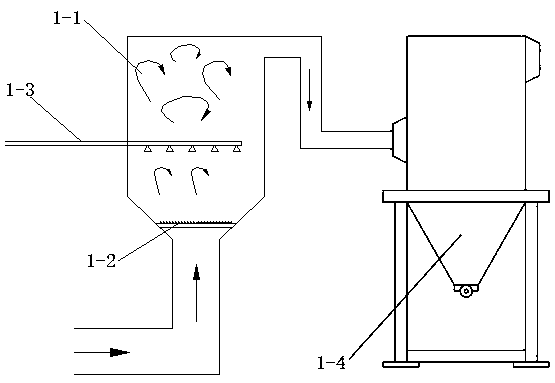

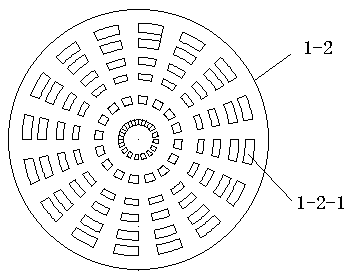

[0021] Such as figure 1 As shown, a waste gas treatment device includes a turbulent mixing dust removal device 1, a drying device 2, a pre-filter 3, a zeolite runner concentration device 4, a fan I 5, a chimney 6, a heat exchanger 7, and a rotary RTO incineration device 8. Fan II 9, the air outlet of the turbulent mixing dust removal device 1 is connected to the air inlet of the drying device 2 through the air pipe, and the air outlet of the drying device 2 is connected to the air inlet of the pre-filter 3 through the air pipe , the air outlet of the pre-filter 3 is connected to the air inlet of the adsorption area of the zeolite runner concentration device 4 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com