A trimming device for the production of injection molded parts of automobile lamps and its application method

A technology for trimming devices and injection molded parts, applied in the direction of separation methods, grinding drive devices, chemical instruments and methods, etc., can solve problems such as damage to injection molded parts of car lights, achieve good safety performance, ensure good health, and avoid respiratory problems The effect of systematic occupational diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

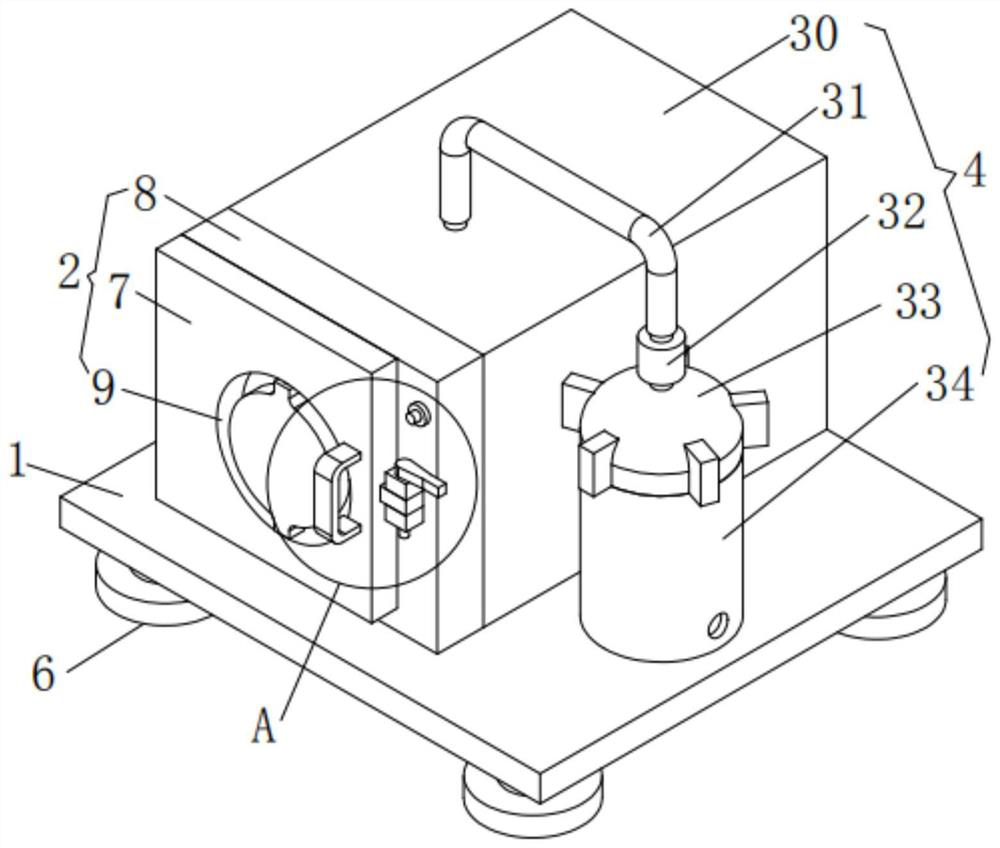

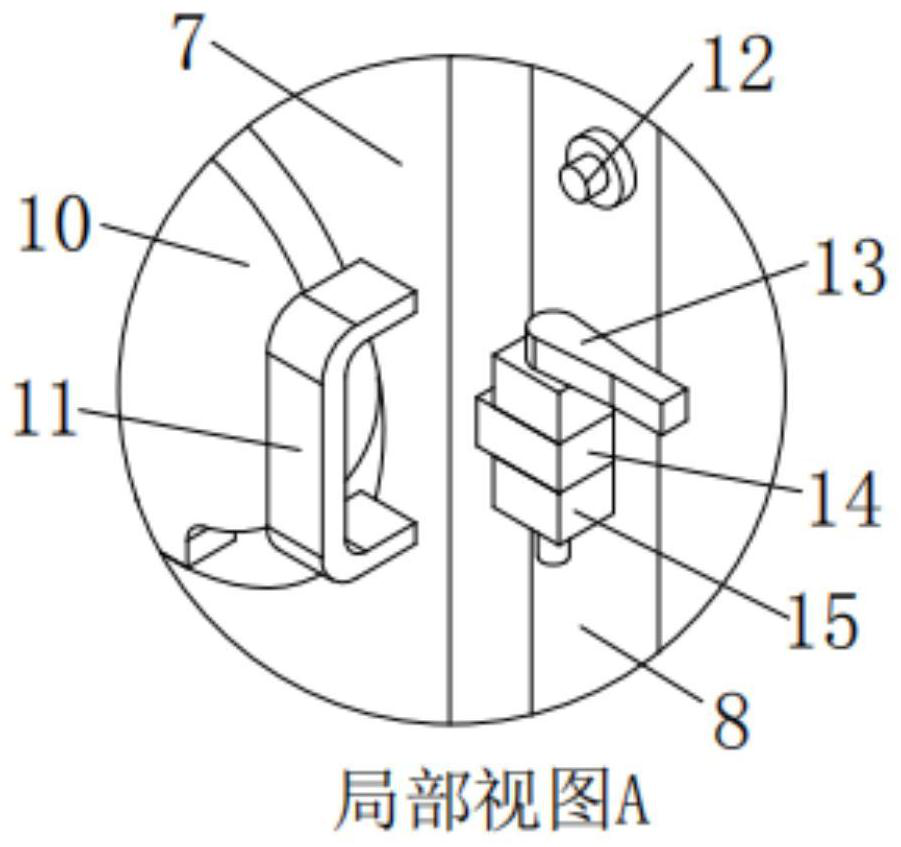

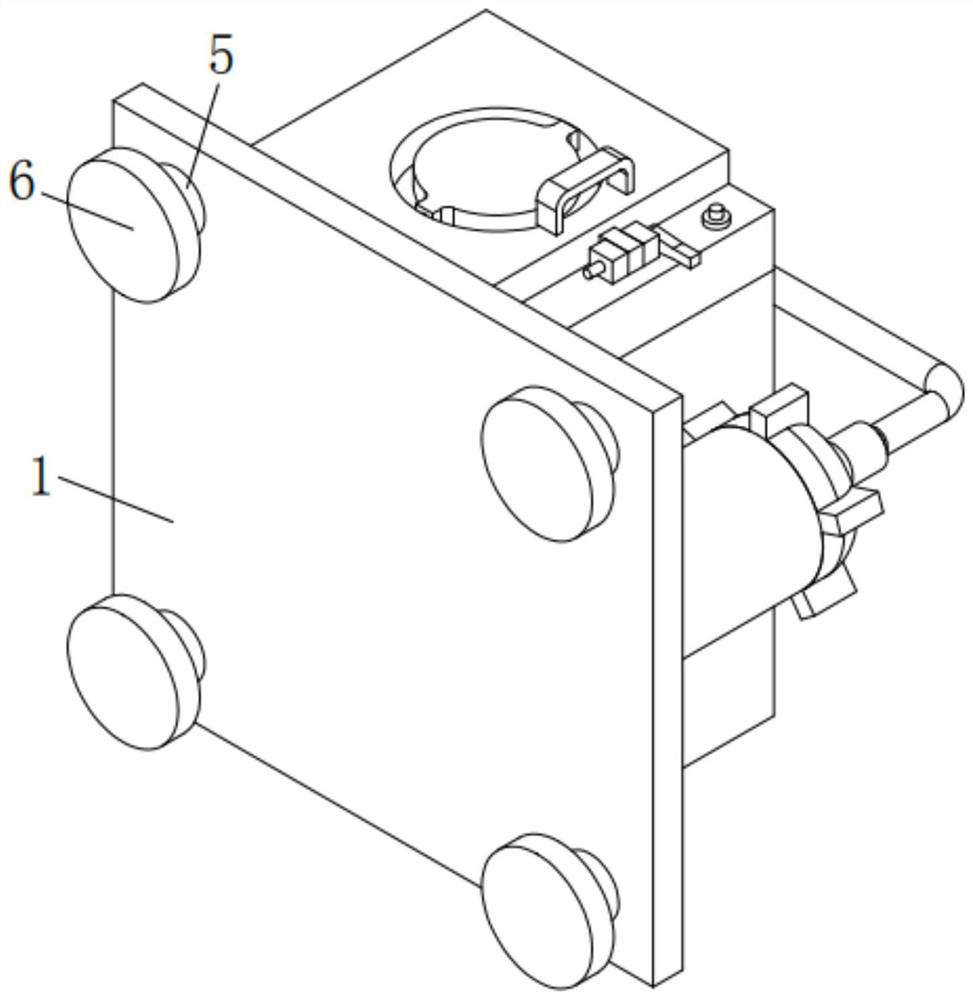

[0049] A trimming device for the production of injection molded parts of car lamps, such as figure 1 and 6 As shown, it includes a base plate 1, a fixing unit 2, a trimming unit 3 and a dust removal unit 4. The base plate 1 is arranged horizontally, the fixing unit 2 is fixedly installed on the upper side of the base plate 1, and the trimming unit 3 is fixedly installed On the other side of the upper part of the bottom plate 1, and the trimming unit 3 is arranged in cooperation with the fixing unit 2, the dust removal unit 4 is fixedly installed on the upper part of the bottom plate 1, and the dust removal unit 4 is connected with the fixed unit 2. The trimming unit 3 is arranged in cooperation.

[0050] By adopting the above technical solution, the fixing unit 2 is used to fix the injection molded part 43 of the lamp instead of the operator directly fixing the injection molded part 43 of the lamp by hand, so as to avoid the unexpected phenomenon that the hand of the operator...

Embodiment 2

[0074] The difference from Example 1 is that a protective layer is provided on the inner wall of the fixing hole 27 and the surface of the pressing plate 10, and the protective layer is prepared by the following method:

[0075] Take the following raw materials and weigh them by weight: 15-20 parts of epoxy resin, 8-12 parts of calcium carbonate powder, 10-12 parts of titanium dioxide powder, 12-18 parts of phenolic resin, 25-35 parts of polyurethane, 3-5 parts of paraffin , 2-4 parts of alcohol ester twelve, 2-4 parts of triethanolamine, 2-4 parts of emulsified silicone oil and 30-40 parts of water;

[0076] S1. Add the weighed paraffin, alcohol ester dodecane, triethanolamine, emulsified silicone oil and water into the mixer and stir for 20-30min at a stirring speed of 500-700r / min to prepare a mixed solution;

[0077] S2. Adding epoxy resin, calcium carbonate powder, titanium dioxide powder, phenolic resin and polyurethane to a pulverizer for pulverization until the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com