High-density intelligent warehousing system and warehousing loading and unloading method

An intelligent warehousing and high-density technology, applied in the field of logistics warehousing, can solve the problems of low utilization rate of storage area and many channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

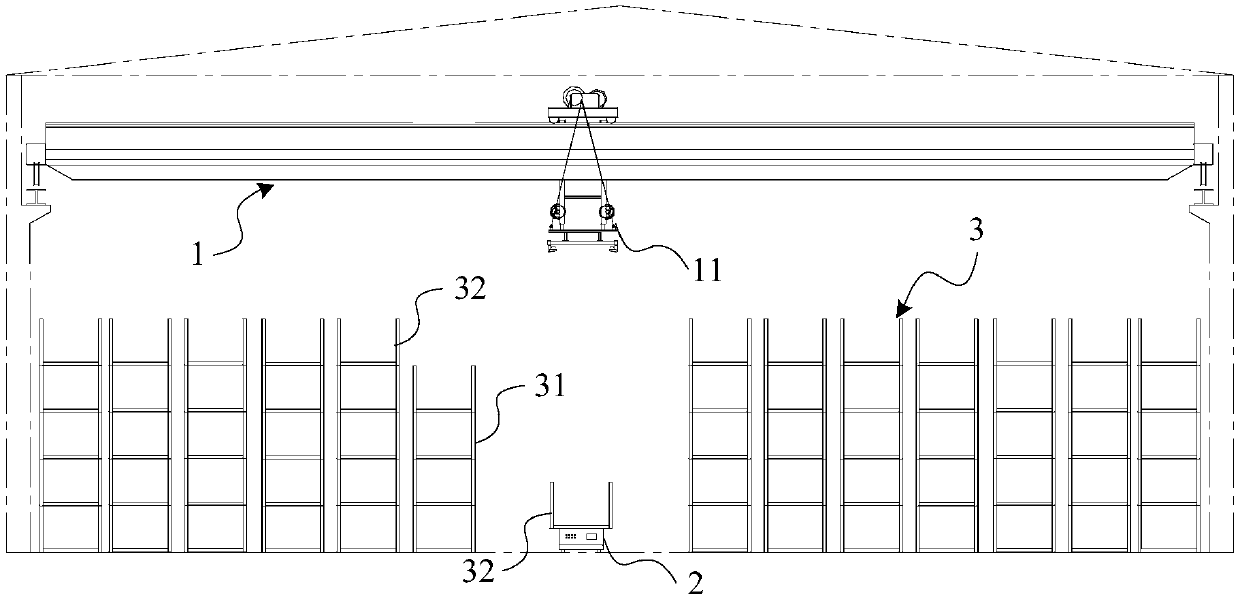

[0027] figure 1 A schematic structural diagram of a high-density intelligent storage system provided in Embodiment 1 of the present invention; figure 1 As shown, the high-density intelligent storage system provided by this embodiment (hereinafter referred to as “storage system”) is applied to warehouses, and the high-density intelligent storage system includes a first conveying device 1 , a second conveying device and a combined shelf 3 .

[0028] The combined shelf 3 includes at least one shelf group 31 , and each shelf group 31 includes at least two vertically stacked shelf units 32 , and the inside of each shelf unit 32 forms a space for accommodating goods. Thus, a plurality of shelf units 32 can be accumulated according to needs in each shelf group 31, and the space in the vertical direction of the warehouse is fully utilized. In the case of limited working capacity in the direction, the stacking height of the shelf unit 32 here can be higher, as long as it does not exce...

Embodiment 2

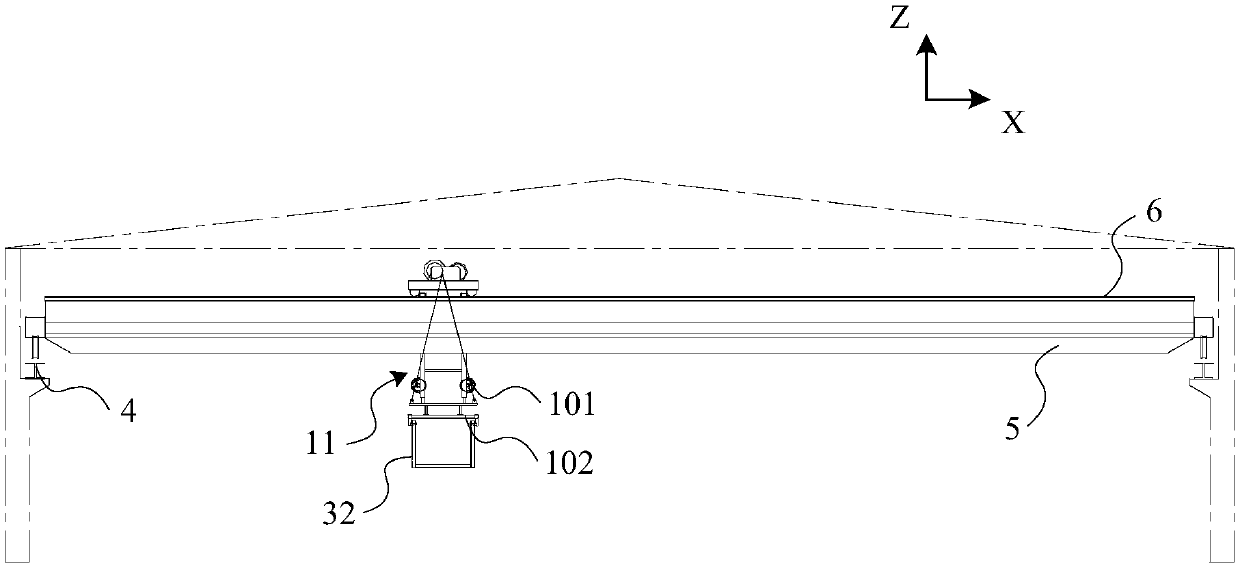

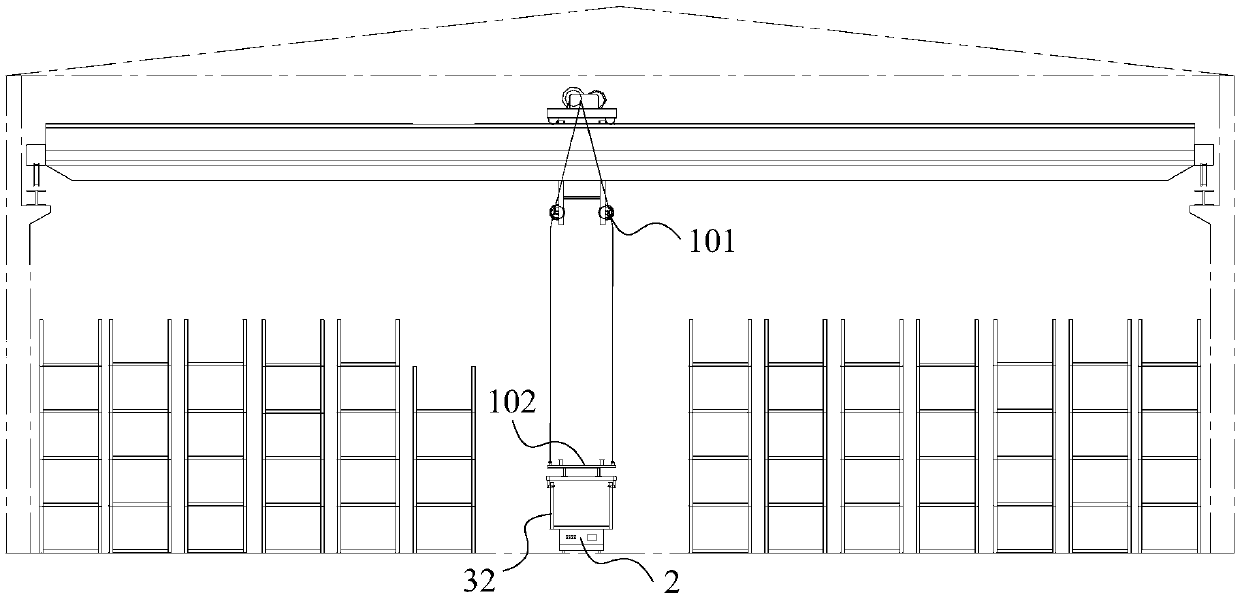

[0042] On the basis of the first embodiment, this embodiment makes further supplementary descriptions on the first conveying device, the shelf unit and the second conveying device in the foregoing first embodiment. figure 2 It is a schematic structural diagram of the first conveying device in the high-density intelligent storage system provided by Embodiment 2 of the present invention. Such as figure 2 As shown, the first conveying device 1 also includes a first horizontal track 4 and a horizontal walking beam 5 positioned on the first horizontal track 4, the length direction of the horizontal walking beam 5 is perpendicular to the first horizontal track 4, and the horizontal walking beam 5 can Move along the first horizontal rail 4; the horizontal walking beam 5 is provided with a second horizontal rail 6, and the trolley 11 is located on the second horizontal rail 6 and can move along the second horizontal rail 6. Such as figure 2 As shown, the X direction in the figure...

Embodiment 3

[0050] Figure 5 The flow chart of the warehouse loading and unloading method provided by Embodiment 3 of the present invention, such as Figure 5 As shown, this embodiment provides a storage loading and unloading method, which is applied to the high-density intelligent storage system described in the first or second embodiment above, which includes:

[0051] S301: Control the first vehicle to perform a cargo loading and unloading operation, where the cargo loading and unloading operation includes one of loading cargo or removing cargo.

[0052] S302: Control the first vehicle to arrive at the designated place, so that the second vehicle located at the designated place can perform cargo loading and unloading operations, wherein the first vehicle is one of the driving and delivery vehicles, and the second vehicle is one of the driving and delivery vehicles the other.

[0053] Here, the types of goods can be selected according to actual needs, and this application does not mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com