High-wear-resistance screen cloth and preparation method thereof

A high wear-resistant, mesh technology, applied in the field of mesh, can solve the problems of unsatisfactory use environment or conditions, general mechanical properties such as strength, and poor comprehensive performance, so as to achieve good comprehensive performance, broad market application prospects, The effect of saving raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

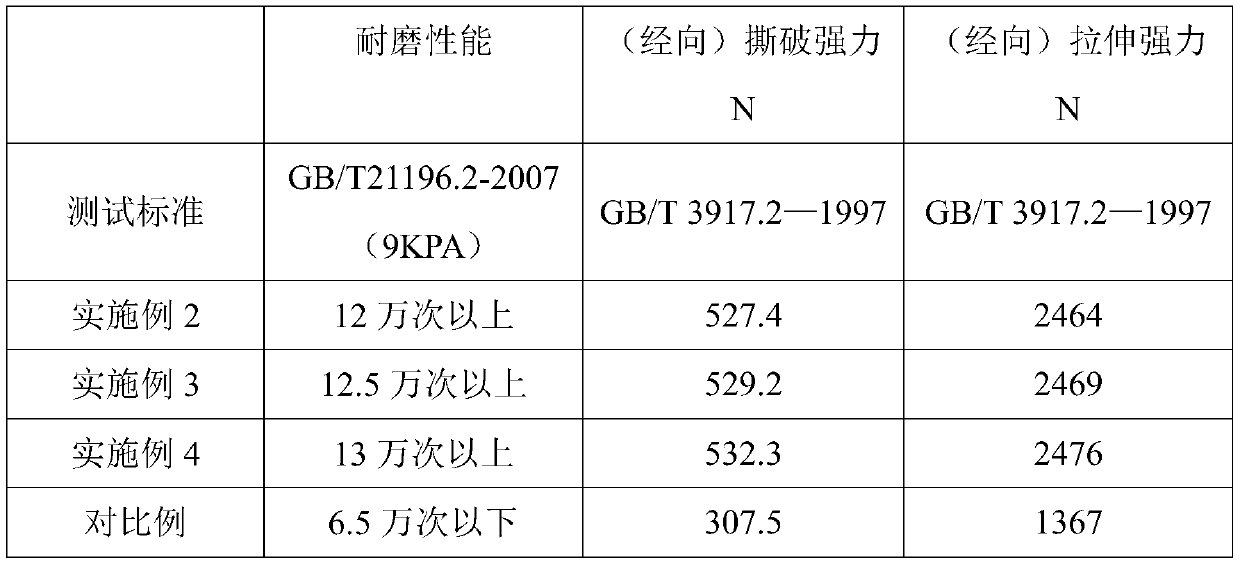

Examples

Embodiment 1

[0067] A kind of high wear-resistant mesh cloth, described high wear-resistant mesh cloth is made by high wear-resistant composite monofilament warp knitting process;

[0068] The high wear-resistant composite monofilament includes an inner layer and an outer layer, and the outer layer is wrapped around the outer periphery of the inner layer;

[0069] The ratio of the cross-sectional area of the inner layer to the outer layer is 10: (7.5-9);

[0070] The inner layer includes the following raw materials in parts by weight:

[0071] 90-95 parts of polyhexamethylene adipamide,

[0072] 5-8 parts of polysepearyl diamine,

[0073] 4-6 parts of carboxylated carbon nanotubes,

[0074] The outer layer includes the following raw materials in parts by weight:

[0075] 13-16 parts of polyhexamethylene adipamide,

[0076] 80-85 parts of polysepearyl diamine,

[0077] 6-8 parts of polybutylene adipamide,

[0078] 2 to 3 parts of graphene.

[0079] 3 to 4.5 parts of nano silicon d...

Embodiment 2

[0109] A kind of high wear-resistant mesh cloth, described high wear-resistant mesh cloth is made by high wear-resistant composite monofilament warp knitting process;

[0110] The high wear-resistant composite monofilament includes an inner layer and an outer layer, and the outer layer is wrapped around the outer periphery of the inner layer;

[0111] The ratio of the cross-sectional area of the inner layer to the outer layer is 10:7.5;

[0112] The inner layer includes the following raw materials in parts by weight:

[0113] 90 parts of polyhexamethylene adipamide,

[0114] 5 parts of polysepearyl diamine,

[0115] 4 parts of carboxylated carbon nanotubes,

[0116] The outer layer includes the following raw materials in parts by weight:

[0117] 13 parts of polyhexamethylene adipamide,

[0118] 80 parts of polysepearyl diamine,

[0119] 6 parts of polybutylene adipamide,

[0120] Graphene 2 parts.

[0121] Nano silicon dioxide 3 parts,

[0122] 3 parts lubricant, ...

Embodiment 3

[0139] A kind of high wear-resistant mesh cloth, described high wear-resistant mesh cloth is made by high wear-resistant composite monofilament warp knitting process;

[0140] The high wear-resistant composite monofilament includes an inner layer and an outer layer, and the outer layer is wrapped around the outer periphery of the inner layer;

[0141] The ratio of the cross-sectional area of the inner layer to the outer layer is 10:9;

[0142] The inner layer includes the following raw materials in parts by weight:

[0143]95 parts of polyhexamethylene adipamide,

[0144] 8 parts of polysepearyl diamine,

[0145] 6 parts of carboxylated carbon nanotubes,

[0146] The outer layer includes the following raw materials in parts by weight:

[0147] 16 parts of polyhexamethylene adipamide,

[0148] 85 parts of polysepearyl diamine,

[0149] 8 parts of polybutylene adipamide,

[0150] 3 parts of graphene.

[0151] Nano silicon dioxide 4.5 parts,

[0152] 5 parts lubricant,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com