Intelligent broken yarn monitoring system based on big data AI for embroidery device

An intelligent monitoring system and big data technology, applied in the direction of embroidery machine, embroidery machine mechanism, textile and papermaking, etc., can solve the problems of affecting processing efficiency, easy to break yarn, time-consuming and labor-intensive, etc., to ensure continuity, improve The effect of textile processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

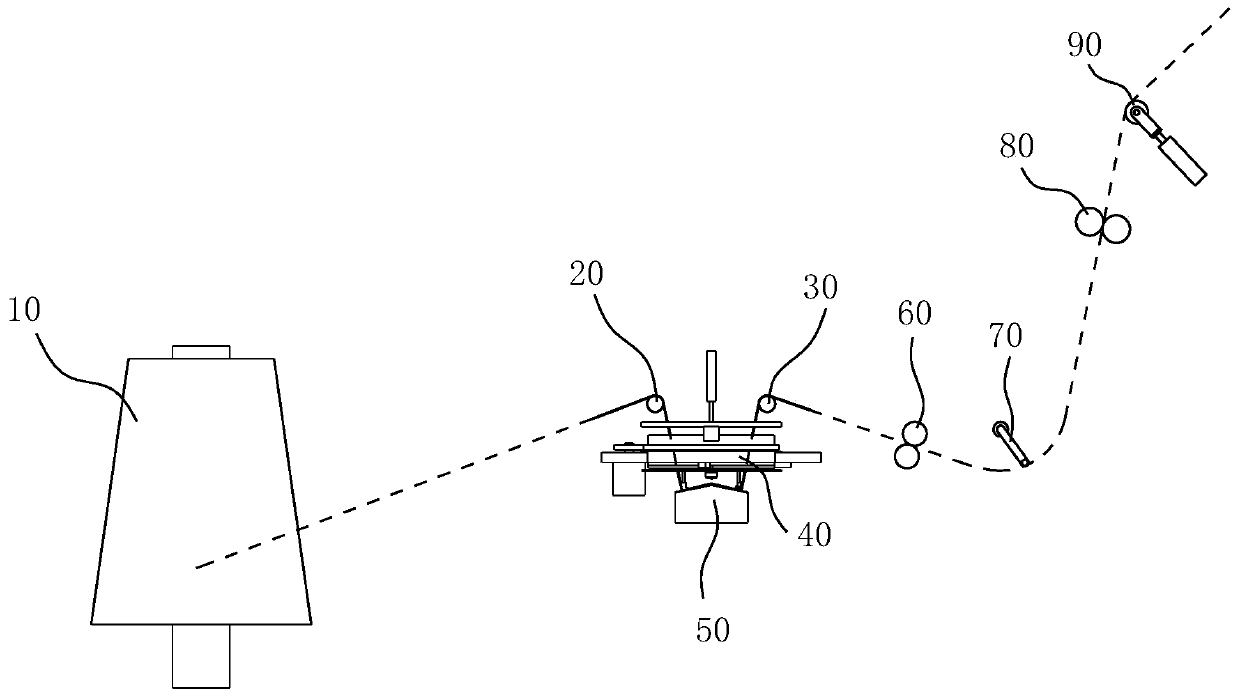

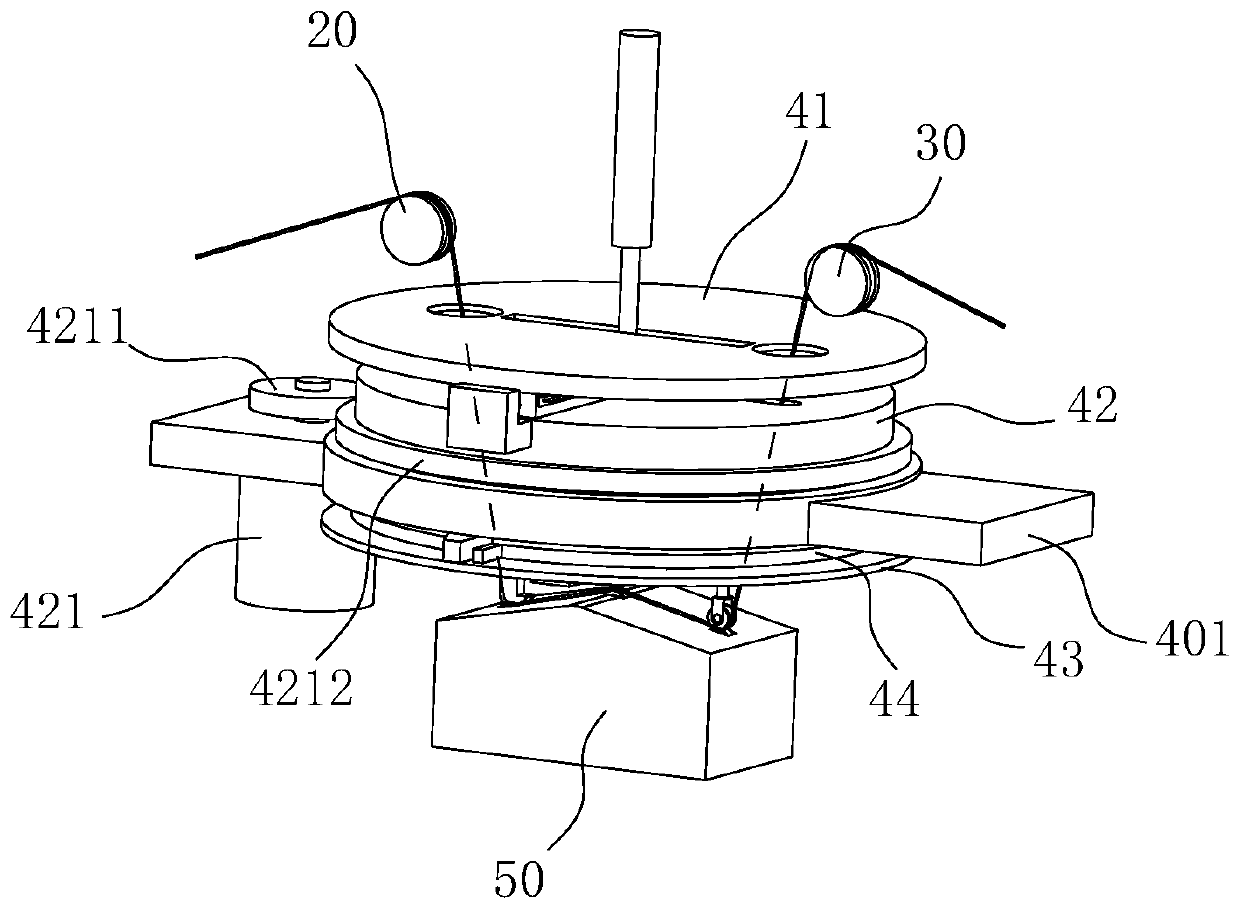

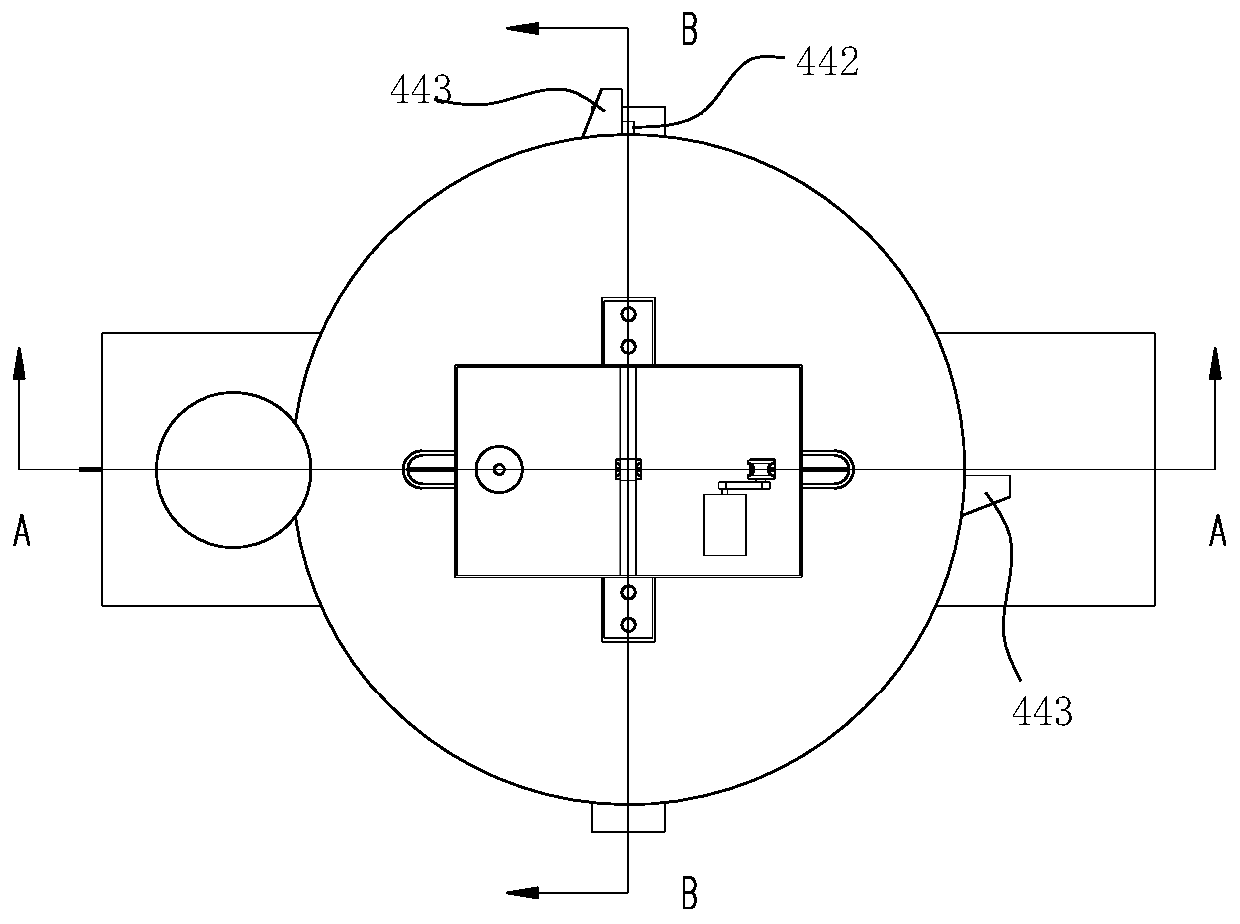

[0028] Such as figure 1 As shown, an intelligent monitoring system for yarn breakage of an embroidery device based on big data AI includes a thread reel 10 for outputting silk thread, and a wire feeding device for transporting the thread on the thread reel 10 to the embroidery mechanism for detecting The first detection mechanism 50 of the tensile strength of the silk thread inside the silk device is used to detect the second detection mechanism 90 of the thread tension between the wire feeding mechanism and the embroidery mechanism. When the silk thread on the first detection mechanism 50 is disconnected, it is used for Its rejoined wiring mechanism 40, and data processing module, data storage module, central processing unit and driving module; Said data processing module is used for receiving the detection signal of first detection mechanism 50 and second detection mechanism 90, said data The storage module is used for storing the ultimate tensile strength experimental detec...

Embodiment 2

[0039] A method for preventing yarn breakage based on the broken yarn intelligent monitoring system shown in embodiment 1, comprising the steps of:

[0040] Step 1: Enter the experimental data of the tensile strength of the silk thread into the data storage module;

[0041] Step 2: Start the wire feeding device, and monitor the detection data of the first detection mechanism 50 and the second detection mechanism 90 in real time; The tensile force of the silk thread is close to the average value of the tensile strength of the experimental data;

[0042] Step 3: When the wire tension detected by the second detection mechanism 90 is greater than the wire tension detected by the first detection mechanism 50, the system automatically controls the second wire feeding roller 80 to accelerate until the wire tension detected by the second detection mechanism 90 is smaller than the first detection The wire pulling force detected by mechanism 50;

[0043] Step 4: When the wire on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com