Agilawood fragrance finished fabric and preparation method thereof

A fragrance and fabric technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problem of long-lasting fragrance, and achieve soft and elegant fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention provides a kind of preparation method of agarwood fragrance finishing fabric, comprises the following steps:

[0037] padding the fabric in a finishing agent solution containing agarwood essential oil microcapsules, and then sequentially pre-baking and baking to obtain the agarwood-flavored finished fabric;

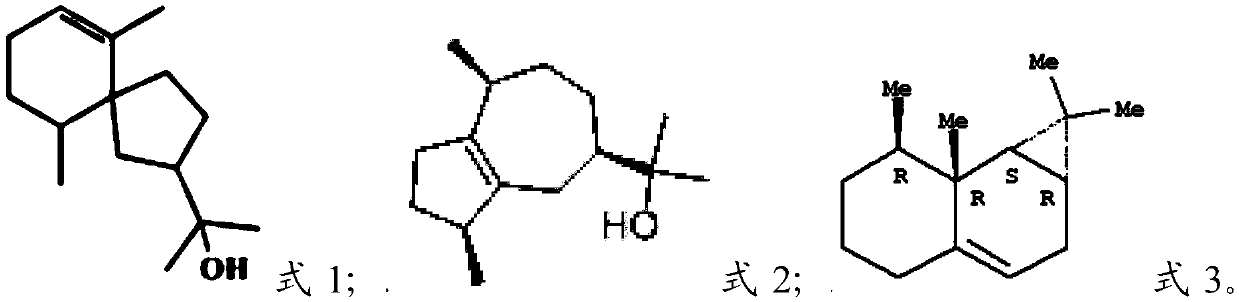

[0038] The agarwood essential oil microcapsule uses the agarwood essential oil as a core material, and the agarwood essential oil contains agarwood helicol, guaiacol and aristolochne.

[0039] After the process method provided by the embodiment of the present invention finishes the fabric, the obtained fabric has a long-lasting agarwood fragrance, which is pleasant and comfortable, and also has certain effects of anti-inflammatory, sterilizing, calming the nerves and anti-depressant, etc., and has broad application prospects in the textile market.

[0040] The embodiments of the present invention can carry out agarwood fragra...

Embodiment 1

[0051] 1. Crush 10kg of Hainan agarwood into 20-30 meshes, then conduct steam distillation, condensation and oil-water separation to obtain a part of agarwood oily extract;

[0052] In addition, 10kg of Hainan agarwood was crushed into 20-30 meshes, and passed through CO at room temperature. 2 Supercritical equipment extraction, pressure 28-30MPa, extraction time 120 minutes; combined with the aforementioned agarwood oily extract, and then undergoing molecular distillation at 150°C under high vacuum for 120 minutes to obtain 80g agarwood essential oil (yellow) .

[0053] The agarwood essential oil includes 89 kinds of volatile components, which include: 1.76% agarwood helicol; 4.9% guaiacol; 2.44% aristolochne according to mass percentage.

[0054] 2. Dissolve 2 g of the obtained agarwood essential oil in ethanol solution, add Tween-80 and sodium lauryl sulfate, and use high-speed shearing to emulsify for 10 minutes to obtain a uniform core material water emulsion; dissolve g...

Embodiment 2

[0059] 1. Crush 10kg of Hainan agarwood into 20-30 meshes, then conduct steam distillation, condensation and oil-water separation to obtain a part of agarwood oily extract;

[0060] In addition, 10kg of Hainan agarwood was crushed into 20-30 meshes, and passed through CO at room temperature. 2 Supercritical equipment extraction, pressure 30-32MPa, extraction time 120 minutes; combined with the above-mentioned agarwood oily extract, followed by high vacuum state molecular distillation treatment, temperature 140°C, processing time 120 minutes, to obtain 100g agarwood essential oil (yellow) .

[0061] The agarwood essential oil includes 89 kinds of volatile components, which include: 1.76% agarwood helicol; 4.9% guaiacol; 2.44% aristolochne according to mass percentage.

[0062] 2. Dissolve 2 g of the obtained agarwood essential oil in ethanol solution, add Tween-80 and sodium lauryl sulfate, and use high-speed shearing to emulsify for 10 minutes to obtain a uniform core materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com