Intelligent super-large-load self-adaptive automatic speed change system with reversing function

A technology of automatic transmission and super load, applied in automatic clutches, electric components, transmission devices, etc., it can solve the problems of low reverse speed, unsatisfactory transmission efficiency, insufficient torque, etc., to reduce friction loss, break through the bearing limit, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

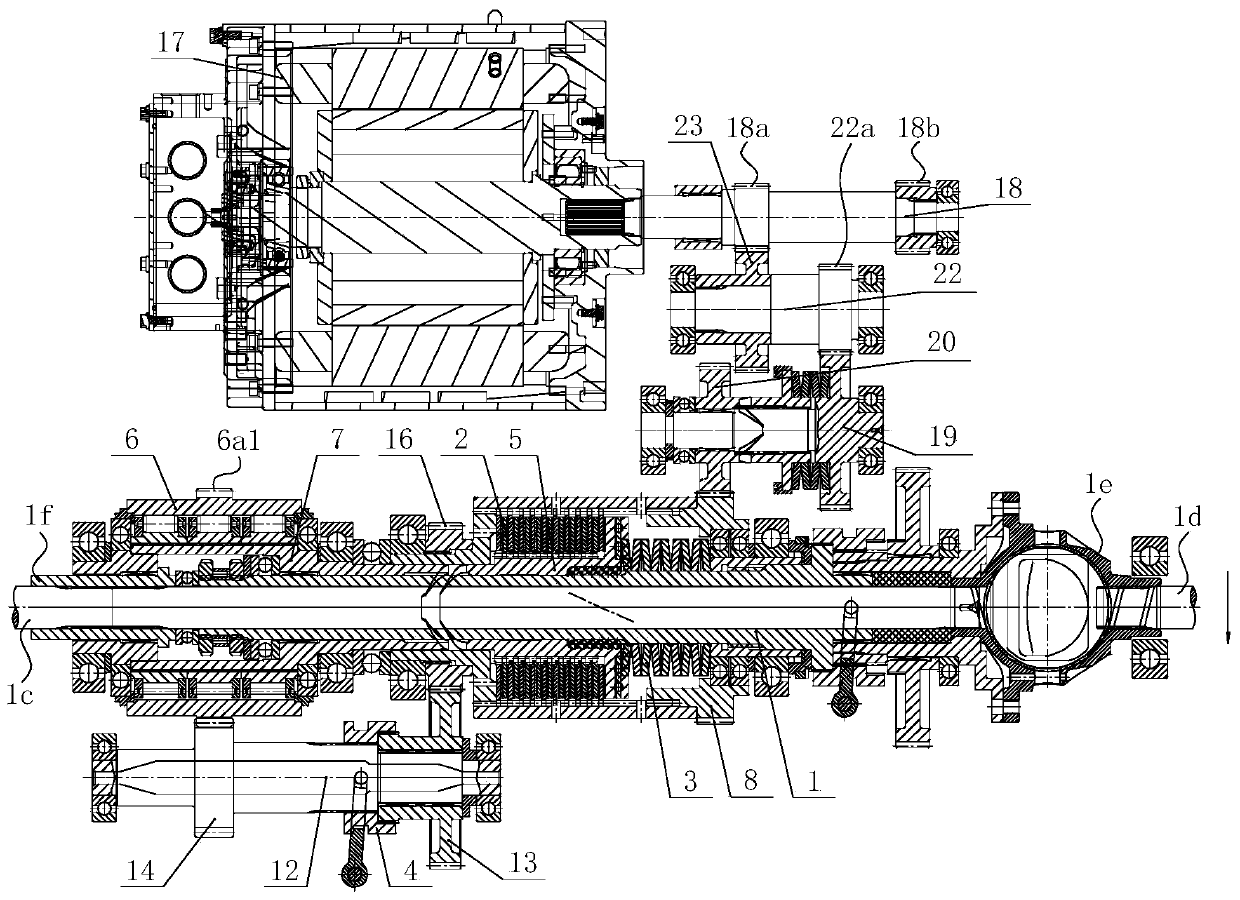

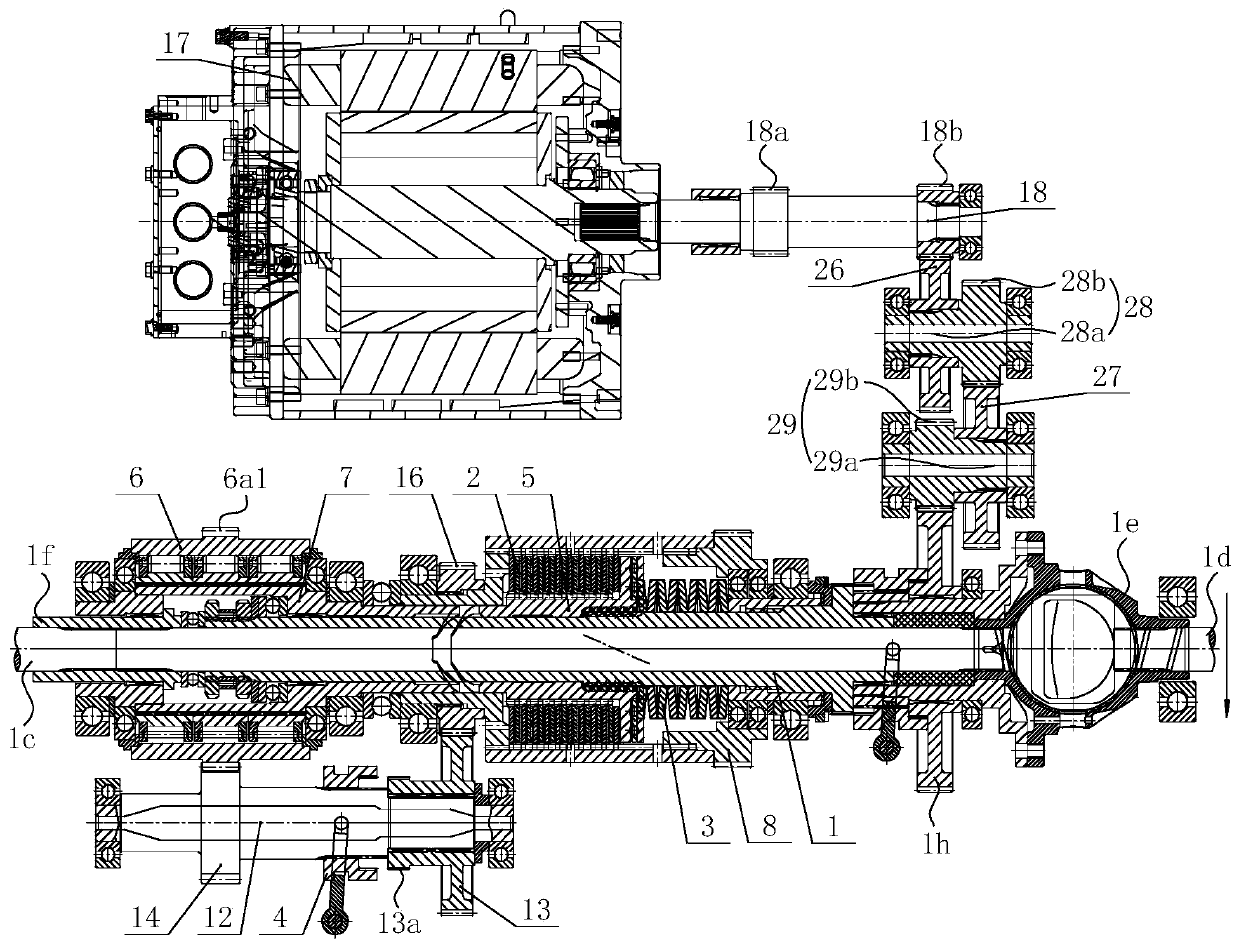

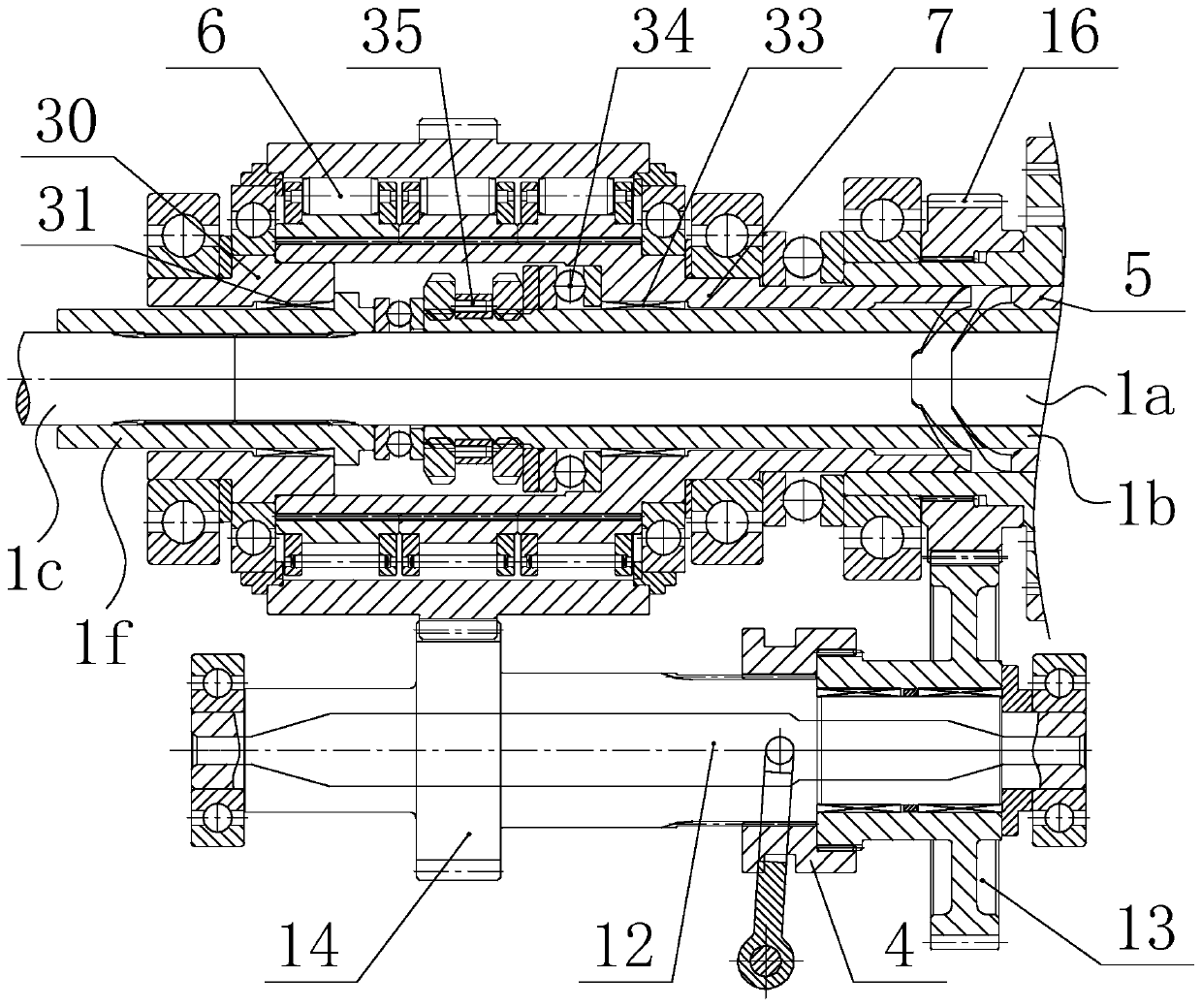

[0041] Such as Figure 1-Figure 5 As shown, an intelligent oversized load adaptive automatic transmission system with reverse gear mainly includes a motor assembly, a forward gear input assembly, a forward gear transmission system, a reverse gear input assembly, a drive axle 1 for outputting power, and The transmission sensing mechanism that transmits power between the forward gear power input assembly and the forward gear transmission system. See figure 1 with figure 2 , The motor assembly includes a motor 17 and a power shaft 18 that can rotate synchronously under the drive of the motor shaft of the motor 17. The power shaft 18 has forward gear output teeth 18a and reverse gear output teeth 18b.

[0042] See figure 1 , the forward gear input assembly includes a power input gear 23 meshing with the forward gear output teeth 18a and a power input shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com