Transformer silicon steel sheet secondary positioning device based on photoelectric detection

A secondary positioning and photoelectric detection technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of low operation efficiency, distance deviation, disassembly and overlap, etc., to improve the quality of finished products and improve positioning accuracy , the effect of improving positioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

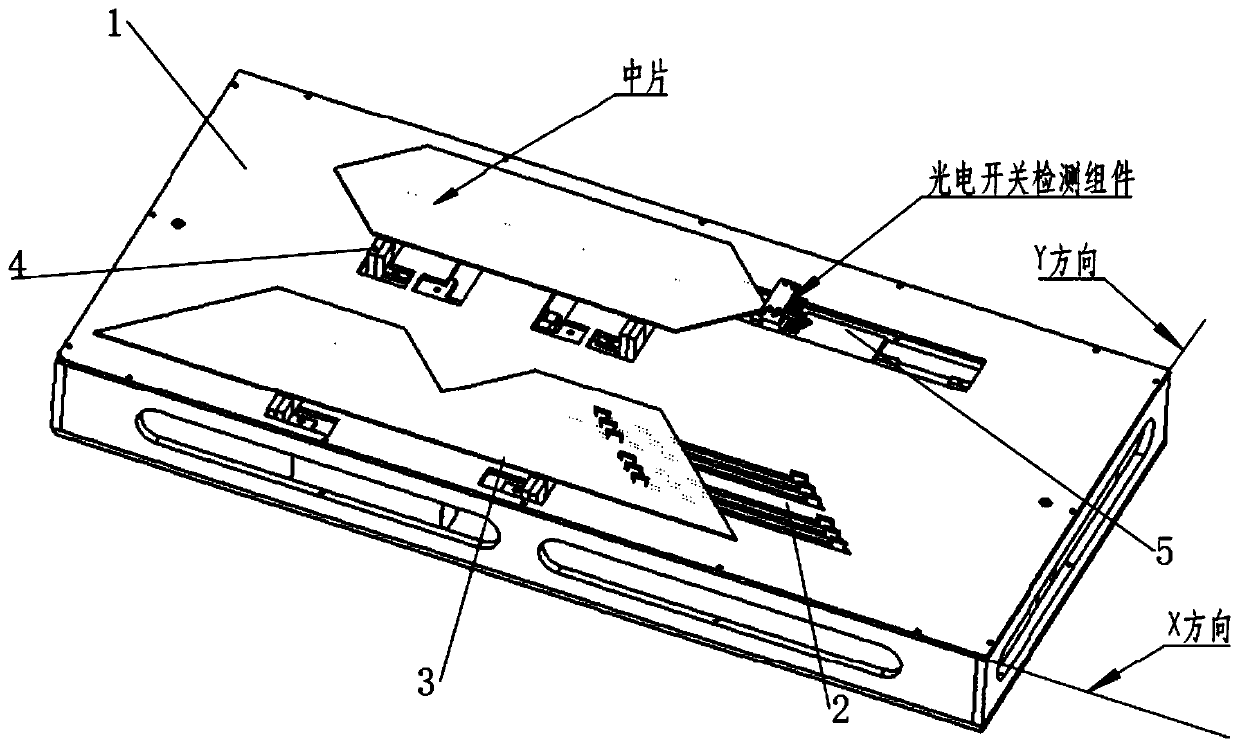

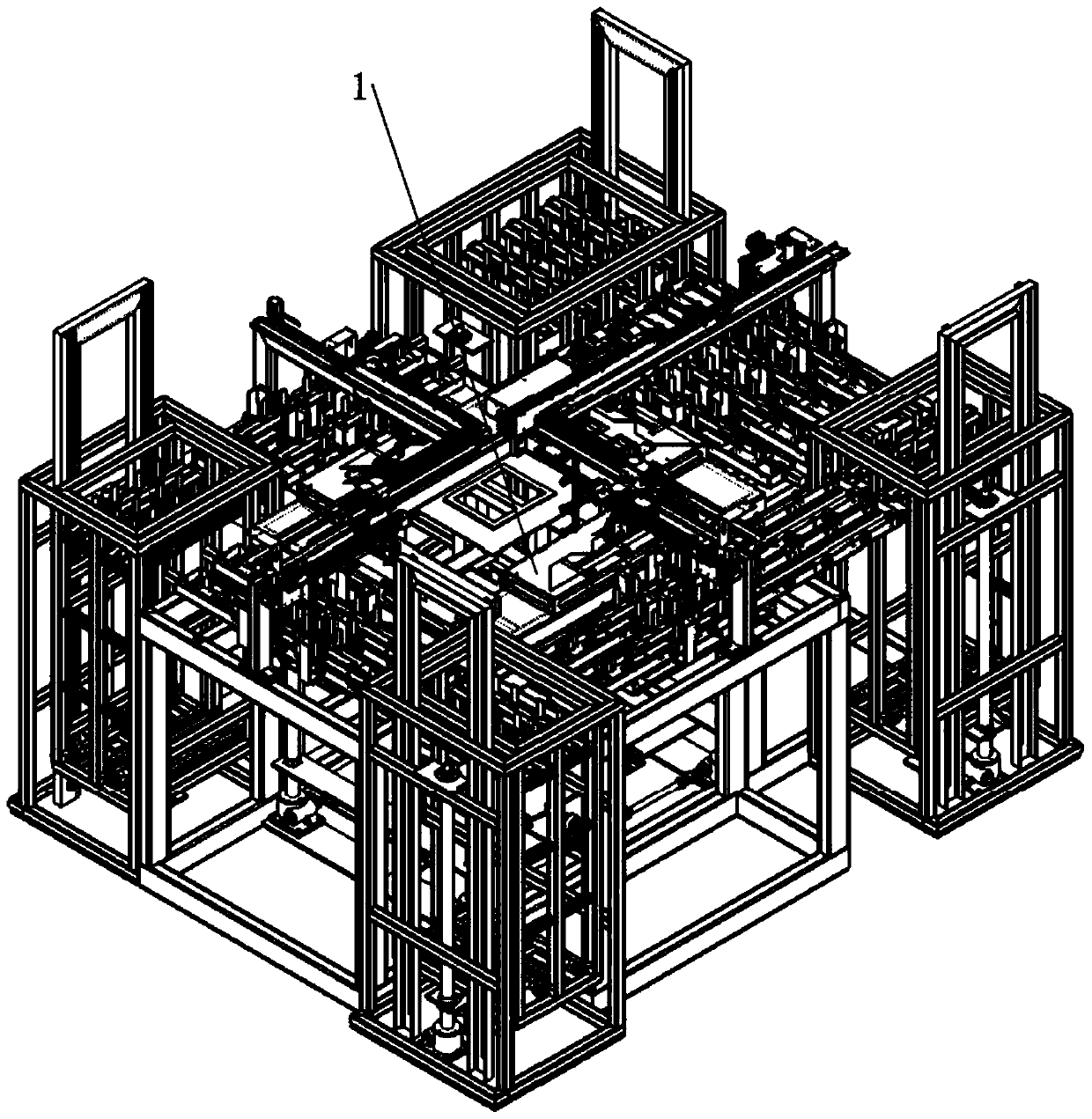

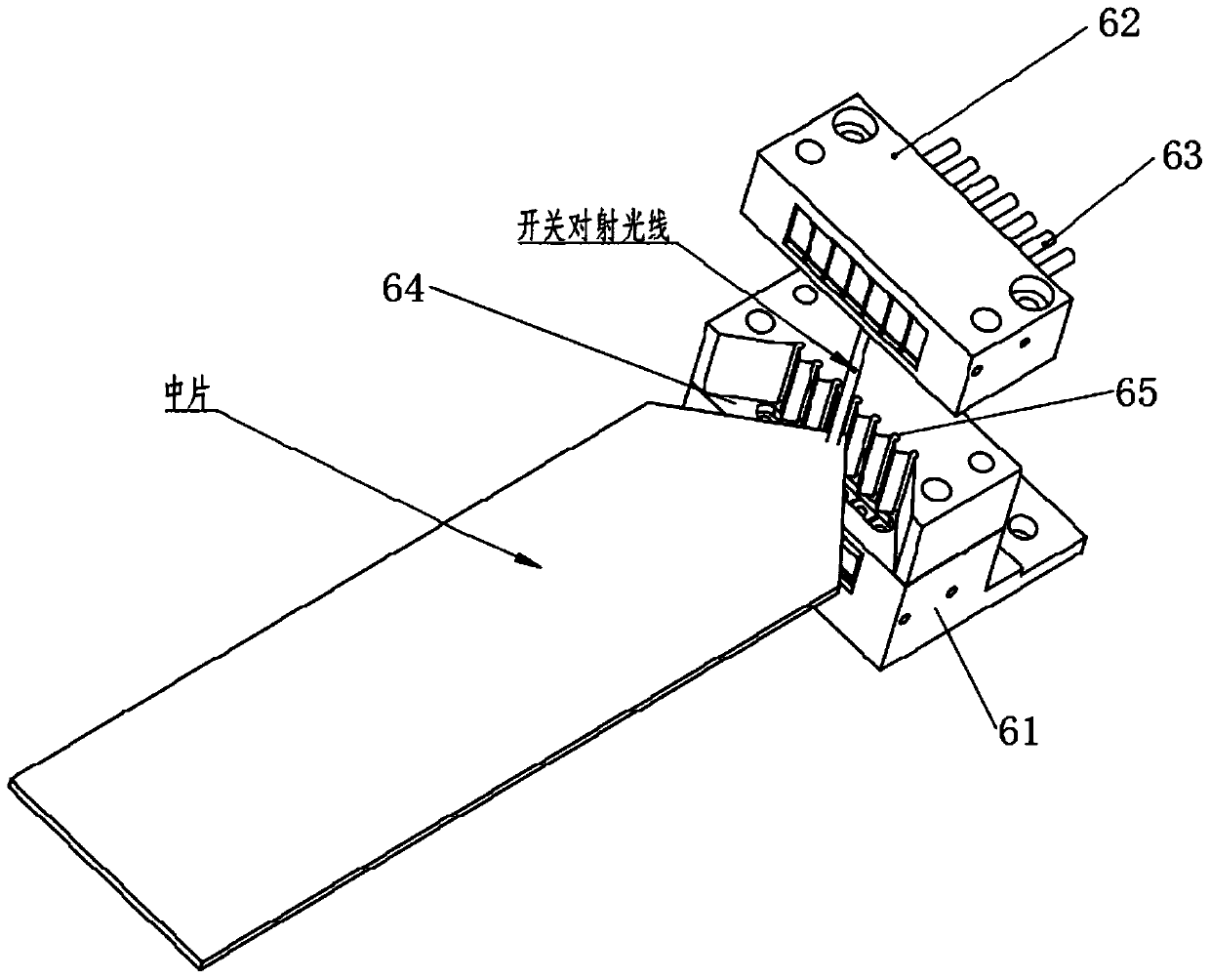

[0048] see Figure 1-2 , a secondary positioning device for transformer silicon steel sheet based on photoelectric detection, which is between the silicon steel sheet feeding and lamination in the prior art, figure 2 It is a complete set of transformer core manufacturing equipment in the prior art, including a positioning platform 1, on which a photoelectric switch detection component, a first horizontal positioning component, a second horizontal positioning component, a first longitudinal positioning component and a second horizontal positioning component are respectively arranged. Two positioning components, see Figure 3-4 The photoelectric switch detection assembly includes a base part 61 and a mounting part 62, a straight slot 64 is formed between the base part 61 and the mounting part 62, a photoelectric switch part 63 is installed on the mounting part 62, and a photoelectric switch part 63 is dug on the base part 61. Part 63 is matched with the connecting female hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com