Method and device for predicting defect tendency of aluminum alloy semi-continuous casting

A technology for casting defects and prediction methods, applied in the field of aluminum alloy casting, can solve the problems of time-consuming and labor-intensive, low defect prediction accuracy, and difficulty in covering the range of process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

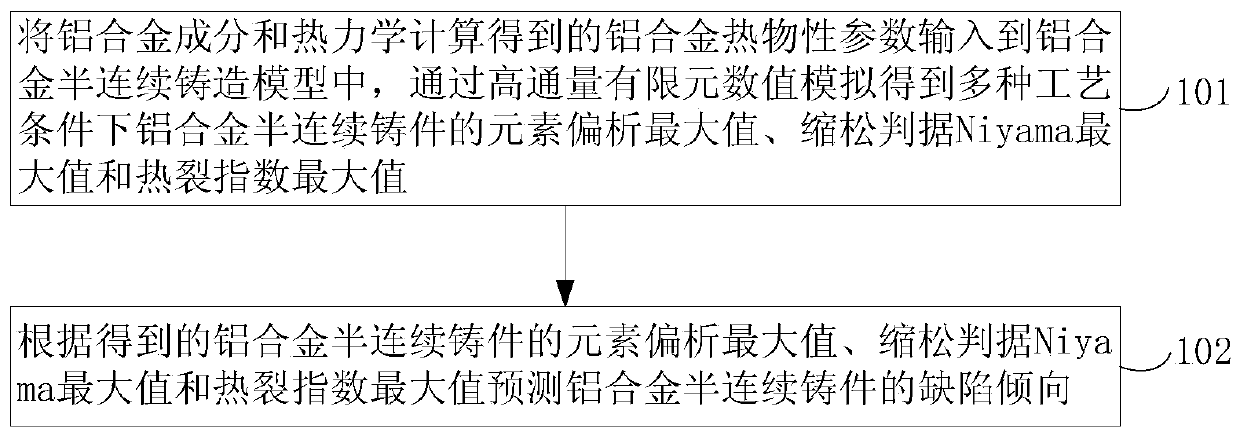

[0031] like figure 1 As shown, the aluminum alloy semi-continuous casting defect tendency prediction method provided by the embodiment of the present invention includes:

[0032] S101, input the aluminum alloy composition and thermodynamic parameters obtained from thermodynamic calculations into the aluminum alloy semi-continuous casting model, and obtain the maximum value of element segregation of aluminum alloy semi-continuous castings under various process conditions through high-throughput finite element numerical simulation , the maximum value of the shrinkage criterion Niyama and the maximum value of the hot tear index;

[0033] S102. Predict the defect tendency of aluminum alloy semi-continuous castings according to the obtained maximum value of element segregation, shrinkage porosity criterion Niyama maximum value and hot cracking index maximum value of aluminum alloy semi-continuous castings.

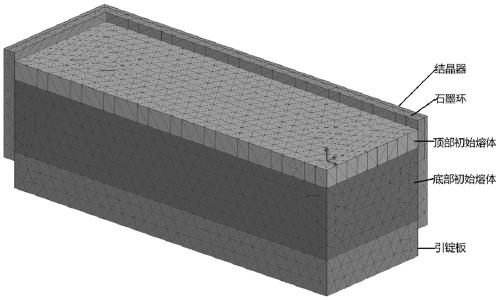

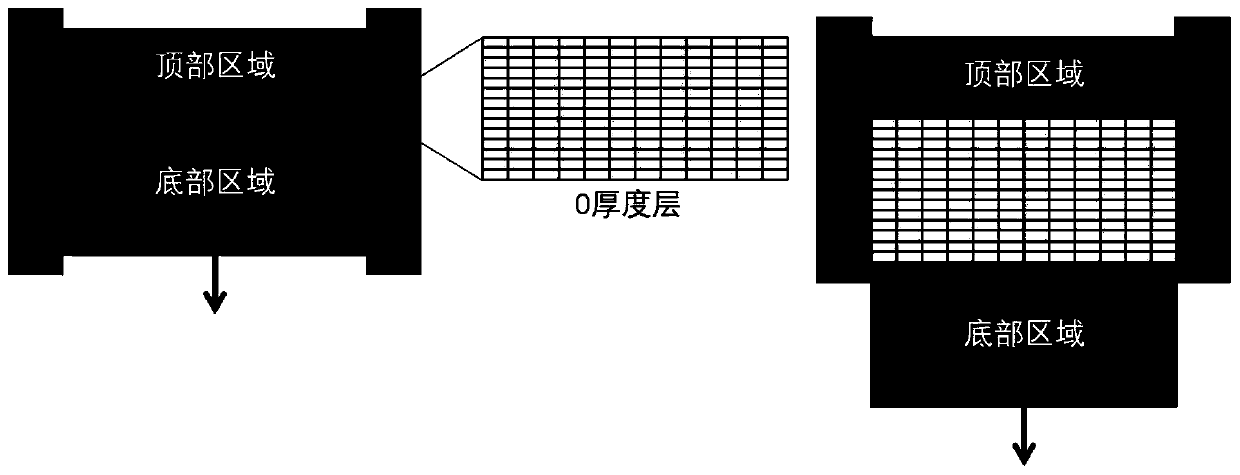

[0034] In the method for predicting the defect tendency of aluminum alloy...

Embodiment 2

[0060] The present invention also provides a specific embodiment of a device for predicting the defect tendency of aluminum alloy semi-continuous castings. Correspondingly, the device for predicting the defect tendency of aluminum alloy semi-continuous castings can realize the purpose of the present invention by performing the process steps in the specific embodiment of the above method, so the explanation in the specific embodiment of the method for predicting the defect tendency of aluminum alloy semi-continuous casting, It is also applicable to the specific implementation of the aluminum alloy semi-continuous casting defect tendency prediction device provided by the present invention, which will not be repeated in the following specific implementation of the present invention.

[0061] The embodiment of the present invention also provides an aluminum alloy semi-continuous casting defect tendency prediction device, including:

[0062] The first determination module is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com