AlGaN barrier layer in AlGaN/GaN HEMT and growth method of AlGaN barrier layer

A growth method and barrier layer technology, which is applied in the field of AlGaN/GaN HEMT epitaxial structure and its growth, can solve the problem of increasing Al component segregation of AlGaN barrier layer lattice defects, AlGaN barrier layer cannot grow at high temperature, Al atoms and Ga Insufficient atomic surface mobility and other problems, to achieve the effect of improving the two-dimensional electron gas surface density, avoiding lattice defects and Al component segregation, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

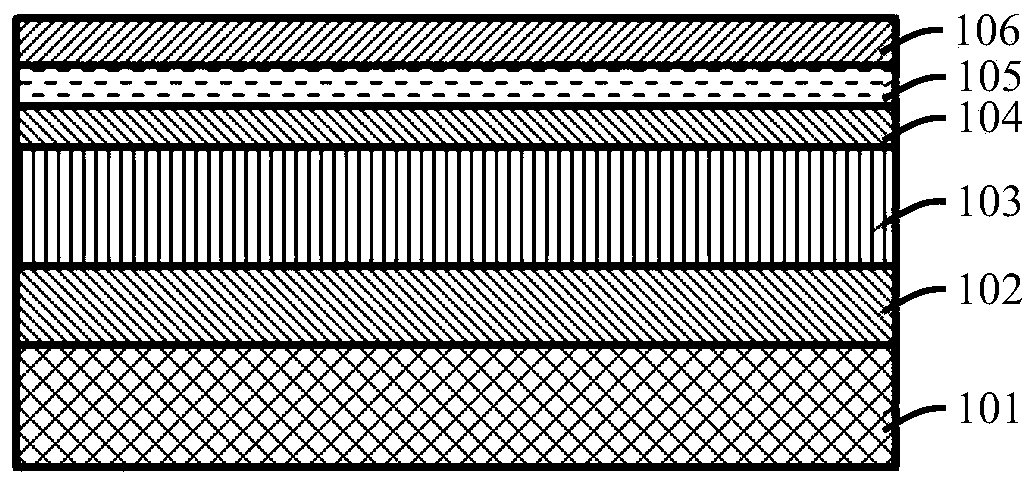

[0020] In order to more clearly illustrate the implementation cases of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

[0021] When performing n-type doping on the AlGaN barrier layer in the prior art, TMAl, TMGa and SiH 4 The problem of reducing the surface mobility of Al atoms and Ga atoms, increasing the lattice defects of the AlGaN barrier layer, and causing the segregation of Al components easily caused by entering the reaction chamber, the present invention proposes a new AlGaN / GaN HEMT The AlGaN barrier layer includes: a non-doped first AlGaN layer, a periodic silicon-doped second A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com