Coolant pumps for internal combustion engines

A technology of coolant pump and internal combustion engine, which is applied in the cooling of the engine, the control of coolant flow, and the components of the pumping device for elastic fluid, etc. , increased wear and other problems, to achieve the effect of small clearance, reduced roughness and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

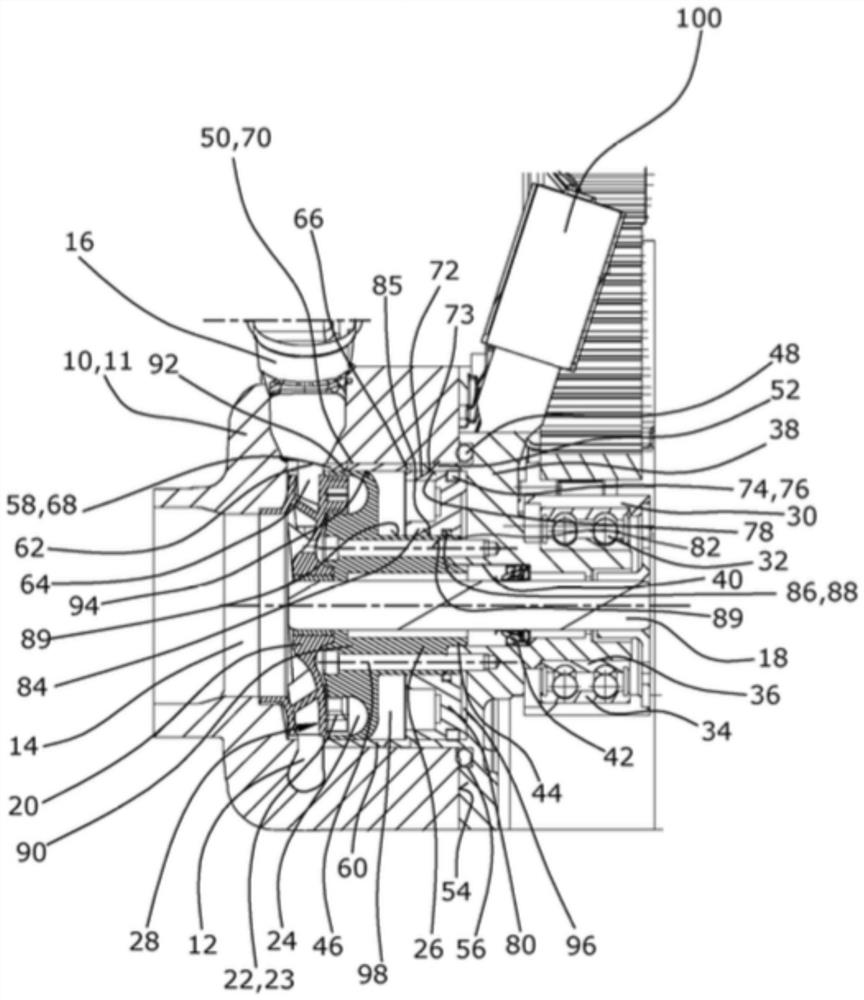

[0030] The coolant pump according to the invention comprises a pump housing 10 with an outer housing part 11, in which a helical delivery channel 12 is formed, in which passage is also formed in the housing An axial pump inlet 14 in the body part 11 sucks in coolant, which is conveyed via a delivery channel 12 to a pump outlet 16 formed tangentially in the outer housing part 11 and into the cooling circuit of the internal combustion engine. Furthermore, the housing part 11 can be formed in one piece, for example, with the crankcase or the cylinder head of the internal combustion engine.

[0031] For this purpose, a coolant pump impeller 20 configured as a radial impeller is fixed radially on the drive shaft 18 within the delivery channel 12 , the rotation of which coolant pump impeller 20 takes place to pump the coolant in the delivery channel 12 . delivery. A control pump wheel 22 is formed on the axial side of the coolant pump wheel 20 opposite the pump inlet 14 , which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com