A supercritical hydrothermal synthesis reaction device coupled with online ultrasonic crushing technology and its hydrothermal synthesis method

A technology of supercritical water and reaction devices, applied in chemical instruments and methods, pressure vessels used in chemical processes, chemical/physical/physicochemical processes that apply energy, etc., can solve problems such as the inability of ultrasonic transducers to fit and use , to achieve the effect of improving product quality, increasing ambient temperature, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

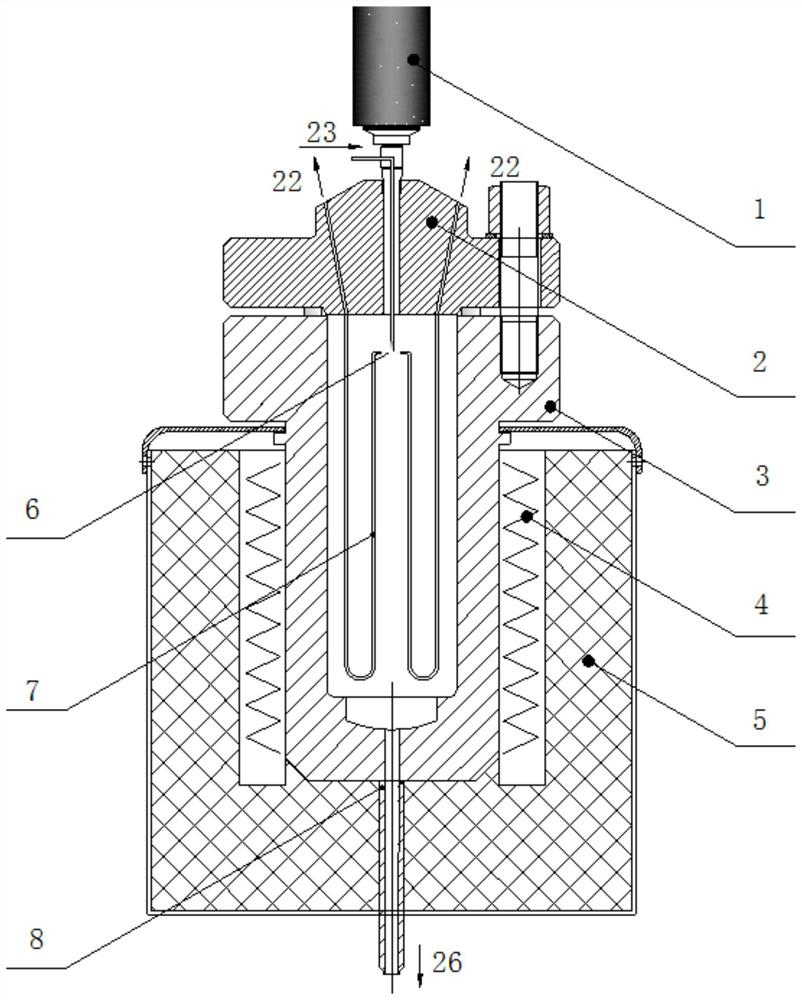

[0042] see figure 1 , a supercritical hydrothermal synthesis reaction device coupled with online ultrasonic crushing technology, comprising an ultrasonic transducer 1, an autoclave and a tubular reactor 7;

[0043] The tubular reactor 7 is placed in the still body 3 of the autoclave, the ultrasonic transducer 1 is fixedly connected to the top cover 2 of the autoclave, and a heating jacket 4 is also provided outside the still body 3 of the autoclave;

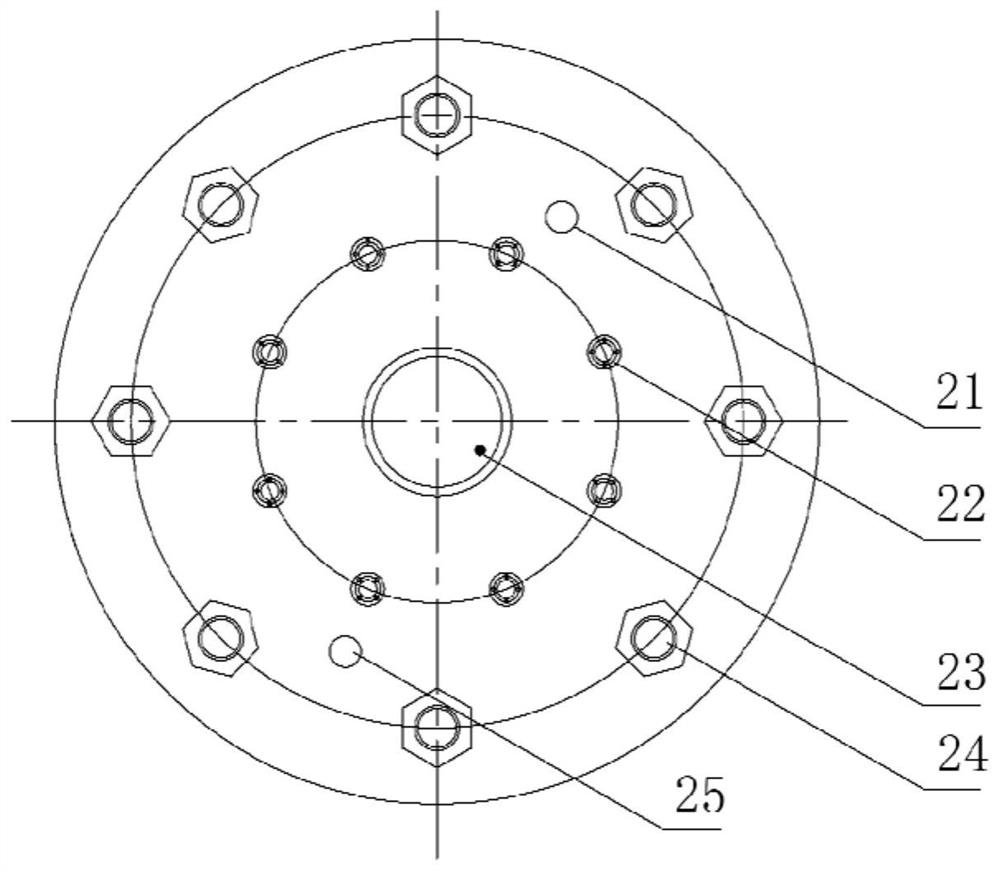

[0044] The top cover 2 is provided with an inlet of the tubular reactor 7 and several pipeline outlets of the tubular reactor 7, and an autoclave outlet 8 is provided at the bottom of the still body 3;

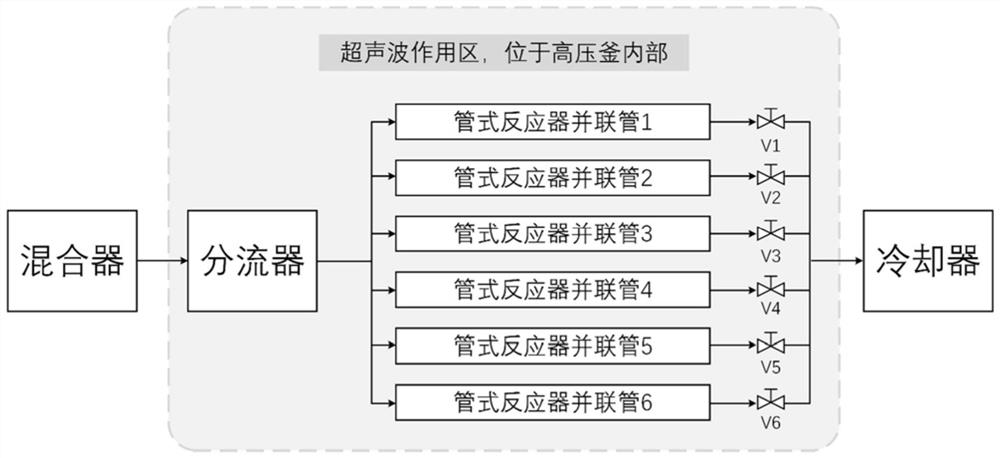

[0045] A flow divider 6 is provided on the inlet pipe of the tubular reactor 7 extending into the still body 3, and the inlet pipe is branched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com