Automatic chain cleaning device

An automatic cleaning and chain technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of automatic cleaning, affecting the operating environment, lack of automatic chain cleaning devices, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

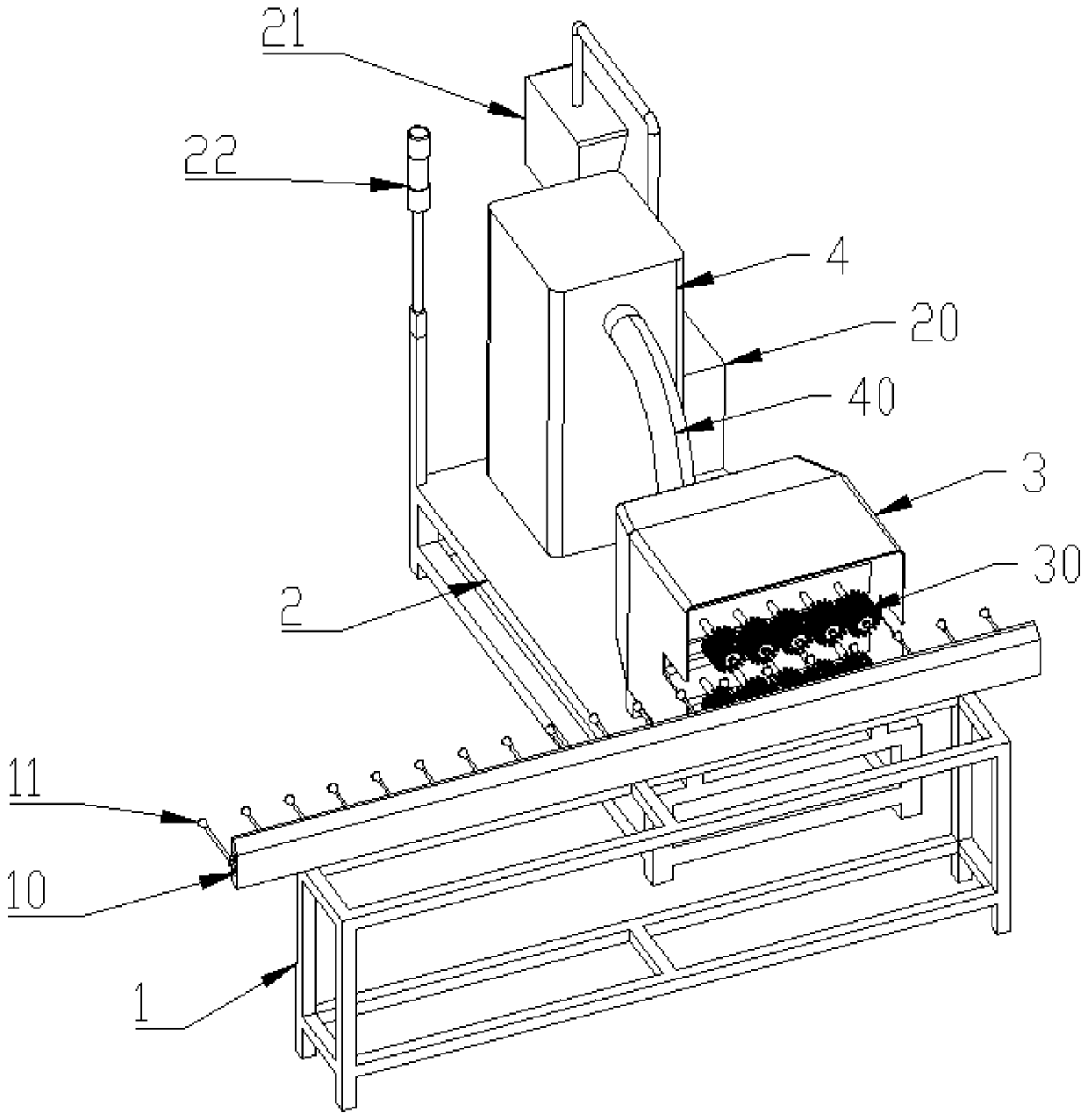

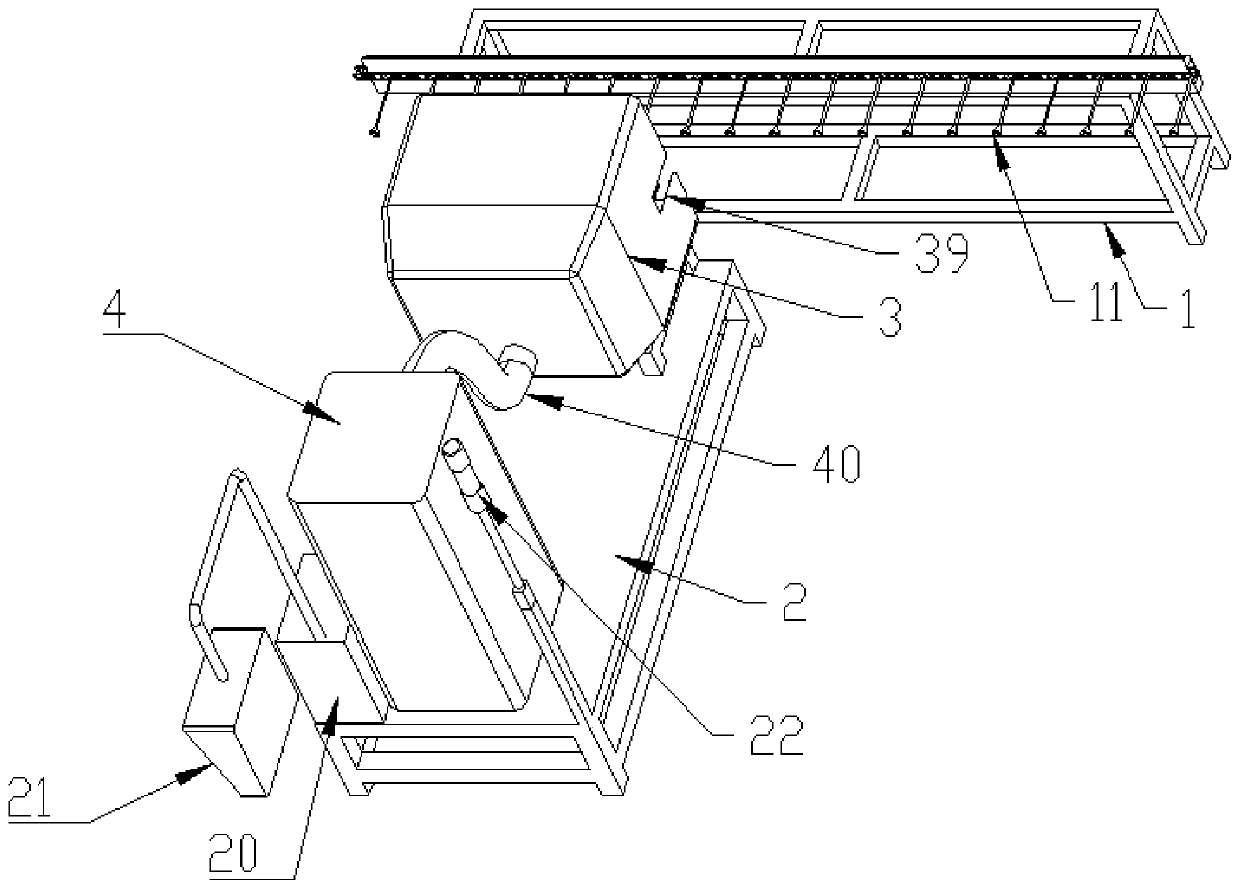

[0022] see Figure 1~6 , in the embodiment of the present invention, a kind of automatic cleaning device of chain, comprises cleaning frame 1 and cleaning box 3, and described cleaning frame 1 is provided with a plurality of suspension shafts 11 that are used to articulate the chain that needs to be cleaned, and described cleaning frame 1 One side of one side is provided with the cleaning box 3 that opening faces suspension shaft 11, and described cleaning box 3 vertical direction is provided with two layers of cleaning brushes 30 that are driven by the motor to rotate, and cleaning frame 1 is opened by the aisle that cleans box 3 sidewalls. Groove 39 penetrates between adjacent cleaning hair brushes 30, described cleaning box 3 inside is provided with the lifting mechanism that drives adjacent cleaning hair brushes 30 to move closer and apart, and the rear side of described cleaning box 3 is provided with for cleaning hair brushes. Brush 30 dust-absorbing air exhaust box 4, d...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is:

[0030] One side of the equipment table 2 is provided with a warning light 22 for reminding, the control end of the warning light 22 is electrically connected with the output end of the control panel 21, and the power supply end of the warning light 22 is electrically connected to the power supply end of the electric box 20. connected.

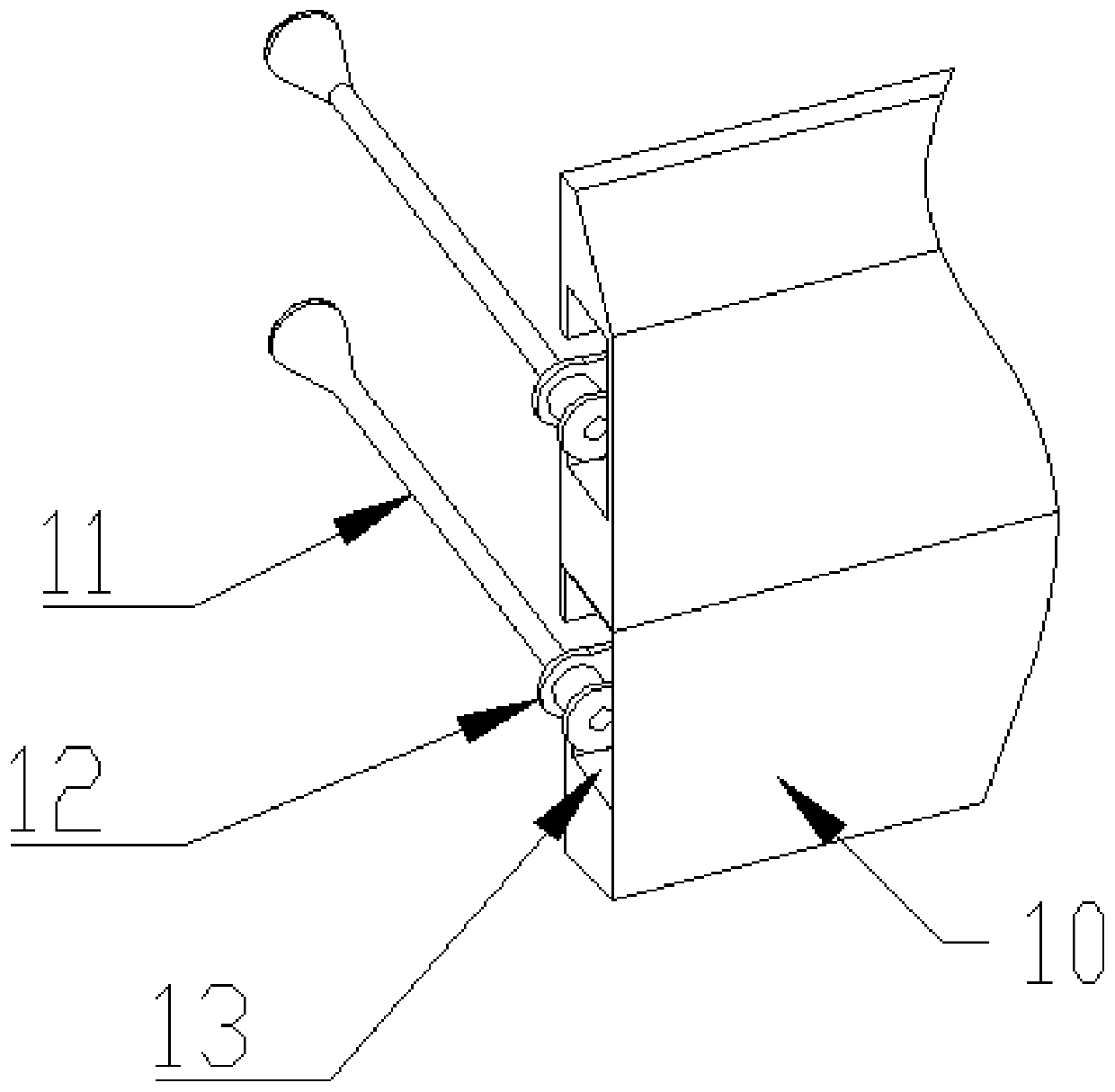

[0031] The front end dimension of described suspension shaft 11 is greater than the rod wall size of suspension shaft 11, here suspension shaft 11 is set to the shape that front end is big and mainly prevents cleaning chain from slipping off from suspension shaft 11 front ends.

[0032] The air exhaust box 4 is provided with a filter screen device for filtering dust, and the filter screen device is installed on the exhaust end of the air exhaust box 4, and the filter screen device provided is mainly used for dust recovery and processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com