Multi-layer station lifting and transmission equipment

A transmission equipment and station technology, applied in metal processing equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of automatic replacement of tire membrane, low production efficiency, low degree of automation, etc., to avoid errors, save manpower, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

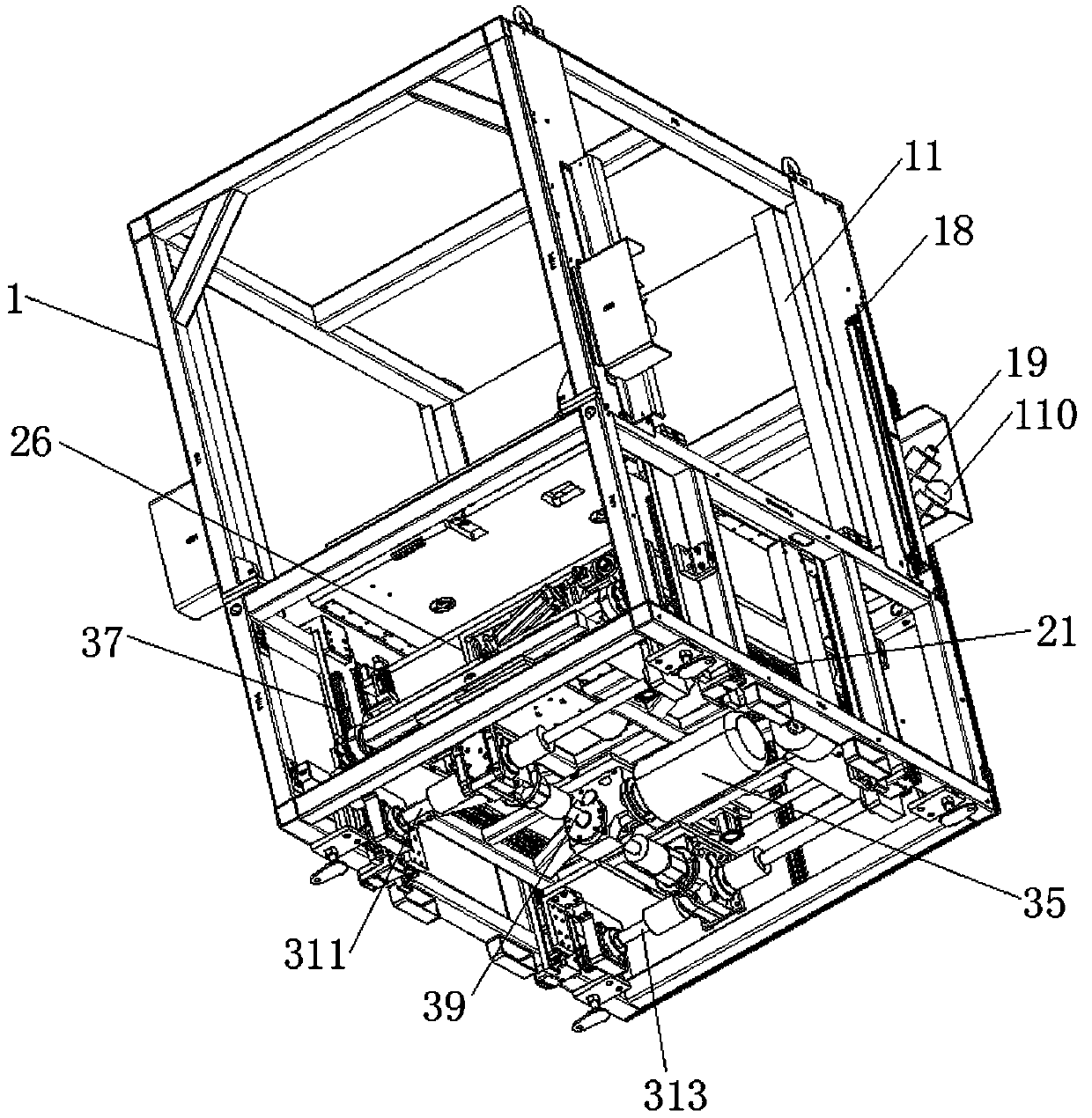

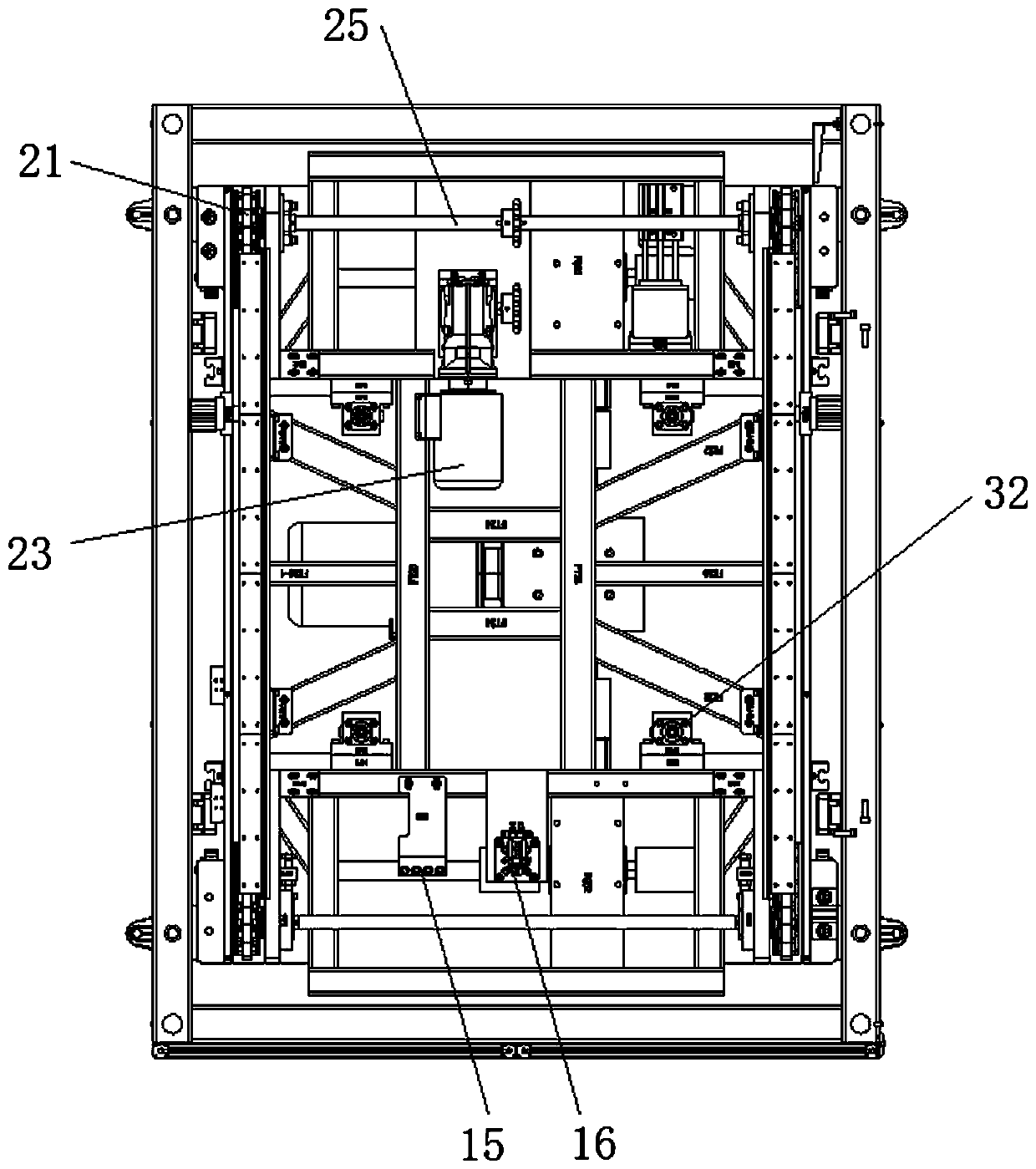

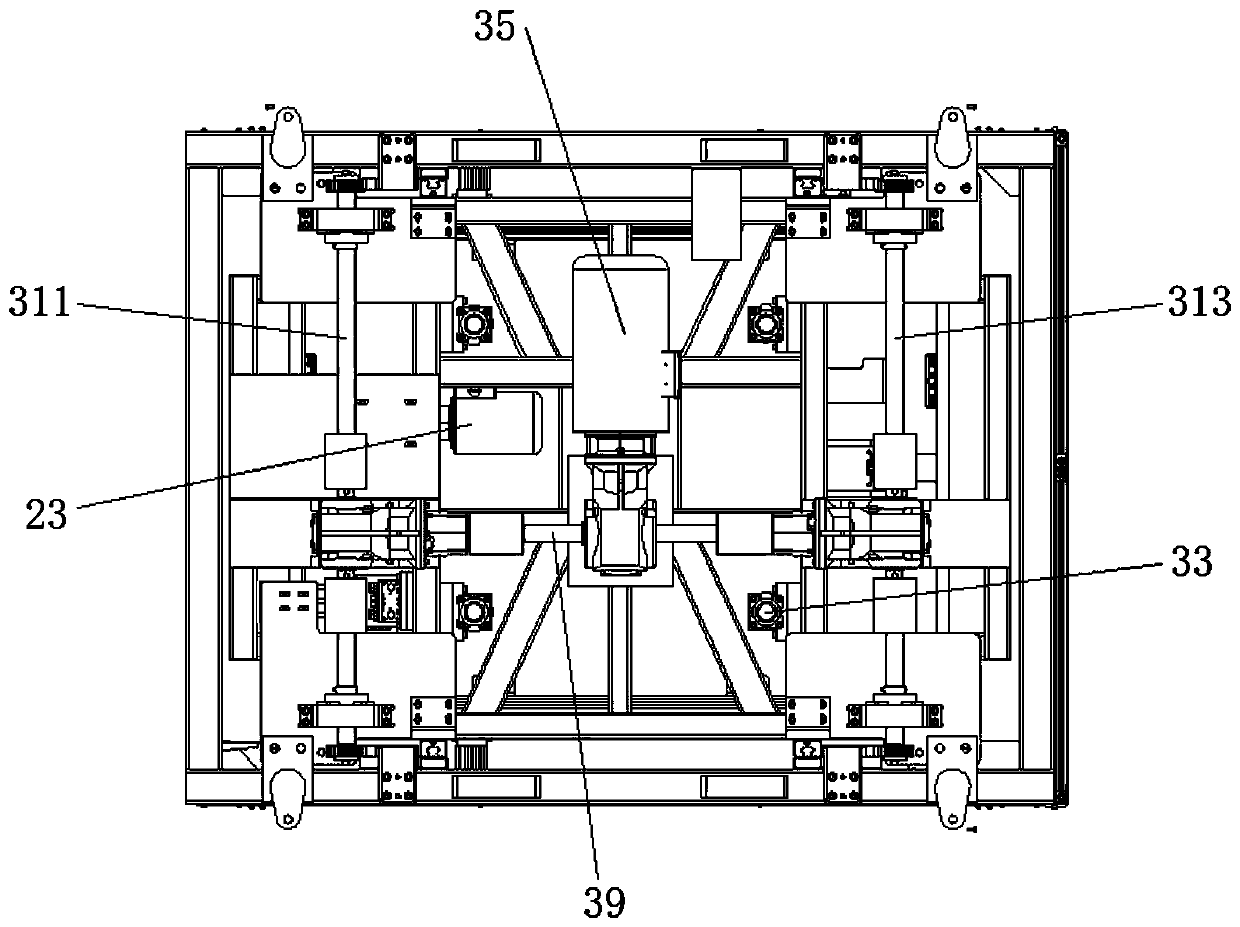

[0023] Embodiment 1, refer to attached Figure 1~6 As shown, it is a structural drawing of multi-layer station lifting and transmission equipment, including a frame body 1 provided with double-layer mold changing positions 12, which can place at least double-layer tire membranes 26, and the tire membranes in the tire membranes 26 The workpiece is compressed and fixed by a reversible presser, and the transmission in the horizontal direction and the vertical direction is realized through the horizontal transmission mechanism 2 and the vertical transmission mechanism 3 . The horizontal transmission mechanism 2 is installed inside the frame body 1, and is provided with a double-speed chain 21 and a first motor 23. The first motor 23 is connected with a horizontal transmission shaft 25 through a horizontal transmission gear sprocket 24, and through the horizontal transmission shaft The gears at both ends of 25 are engaged with double-speed chain 21, and both ends of double-speed ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com