Corrugated board scrap edge collecting device

A collection device and corrugated cardboard technology, applied in the field of corrugated paper production, can solve the problems of falling on the ground on both sides of the production line, trouble, etc., and achieve the effects of convenient collection, reduced loose distribution, and stable collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

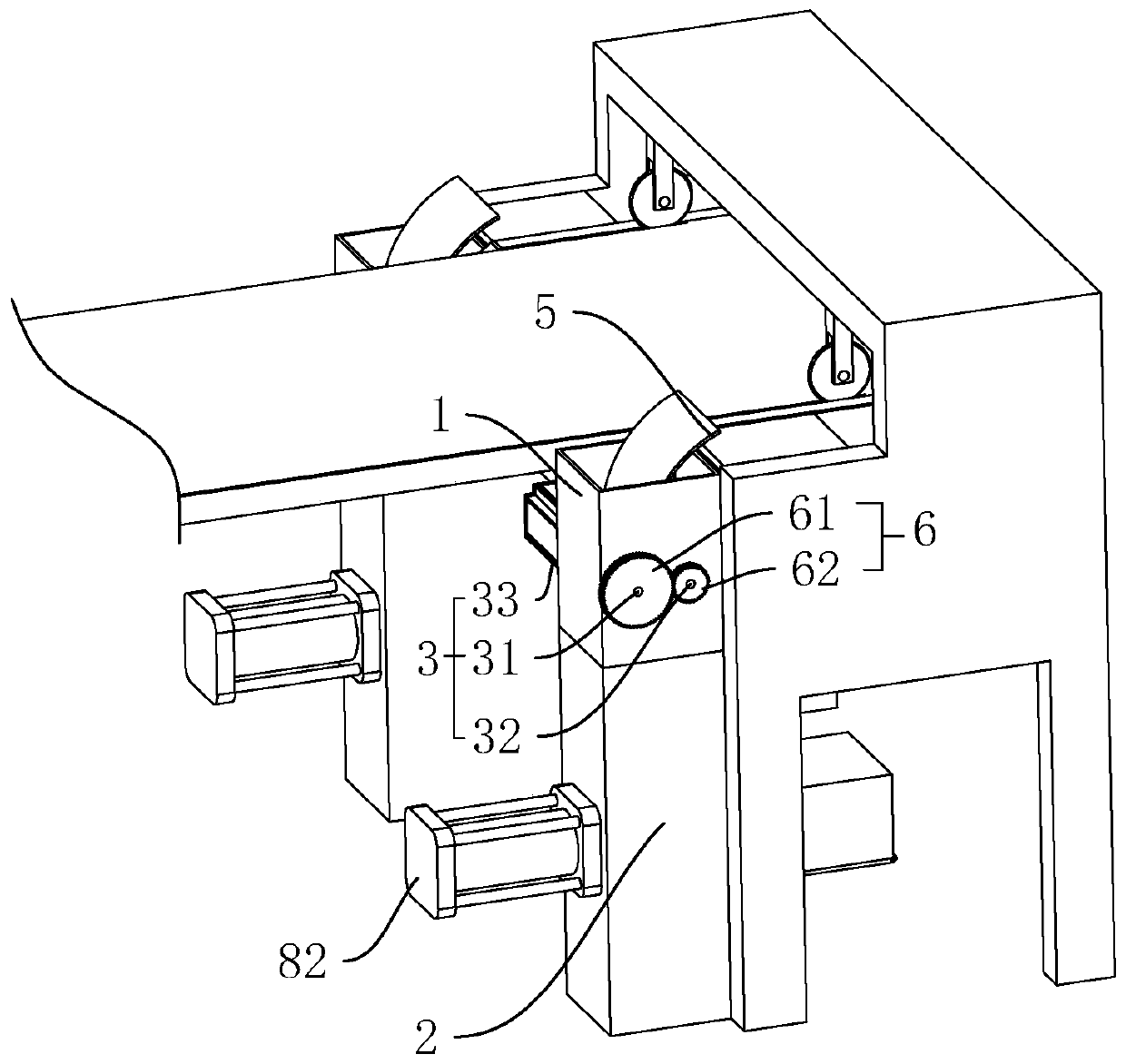

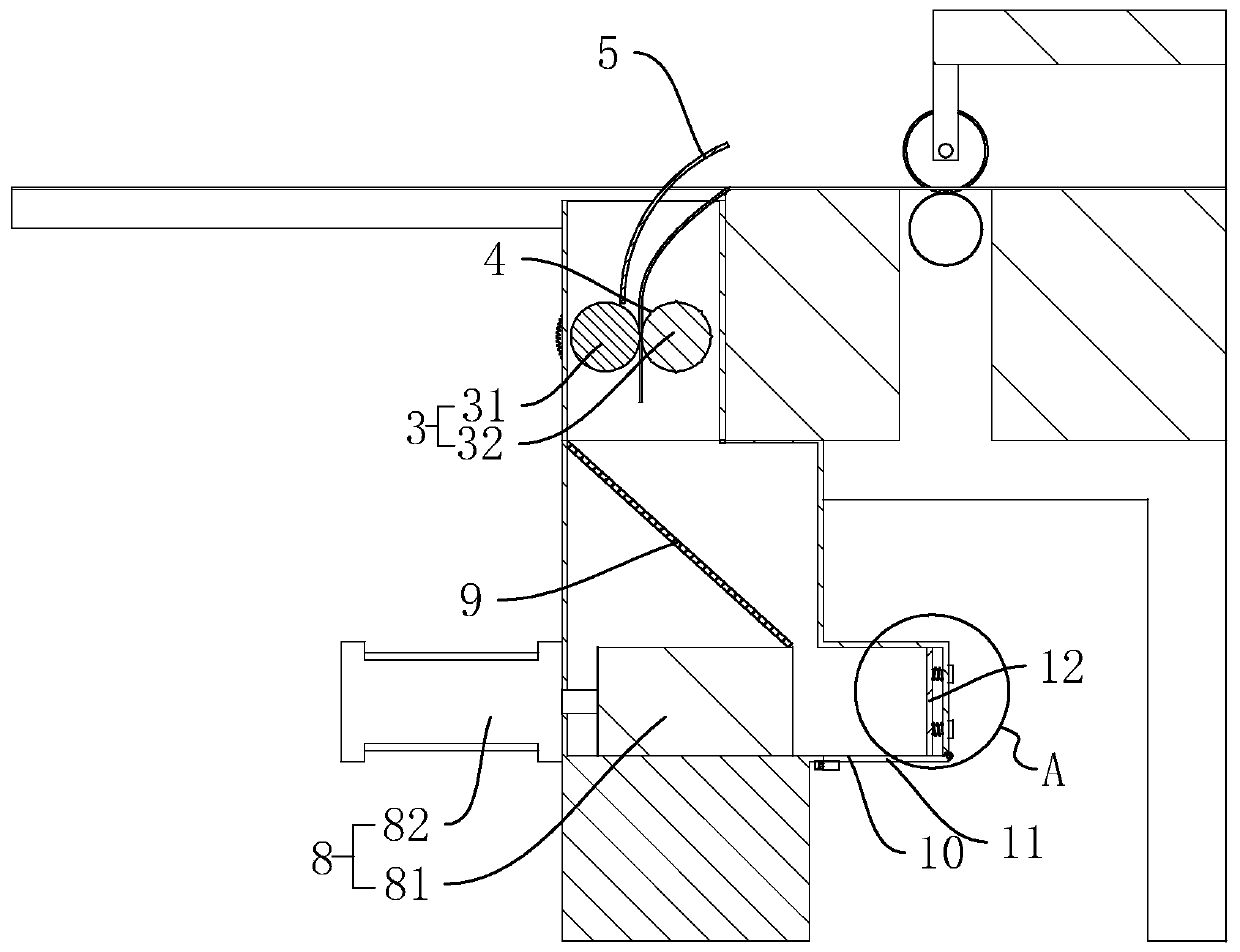

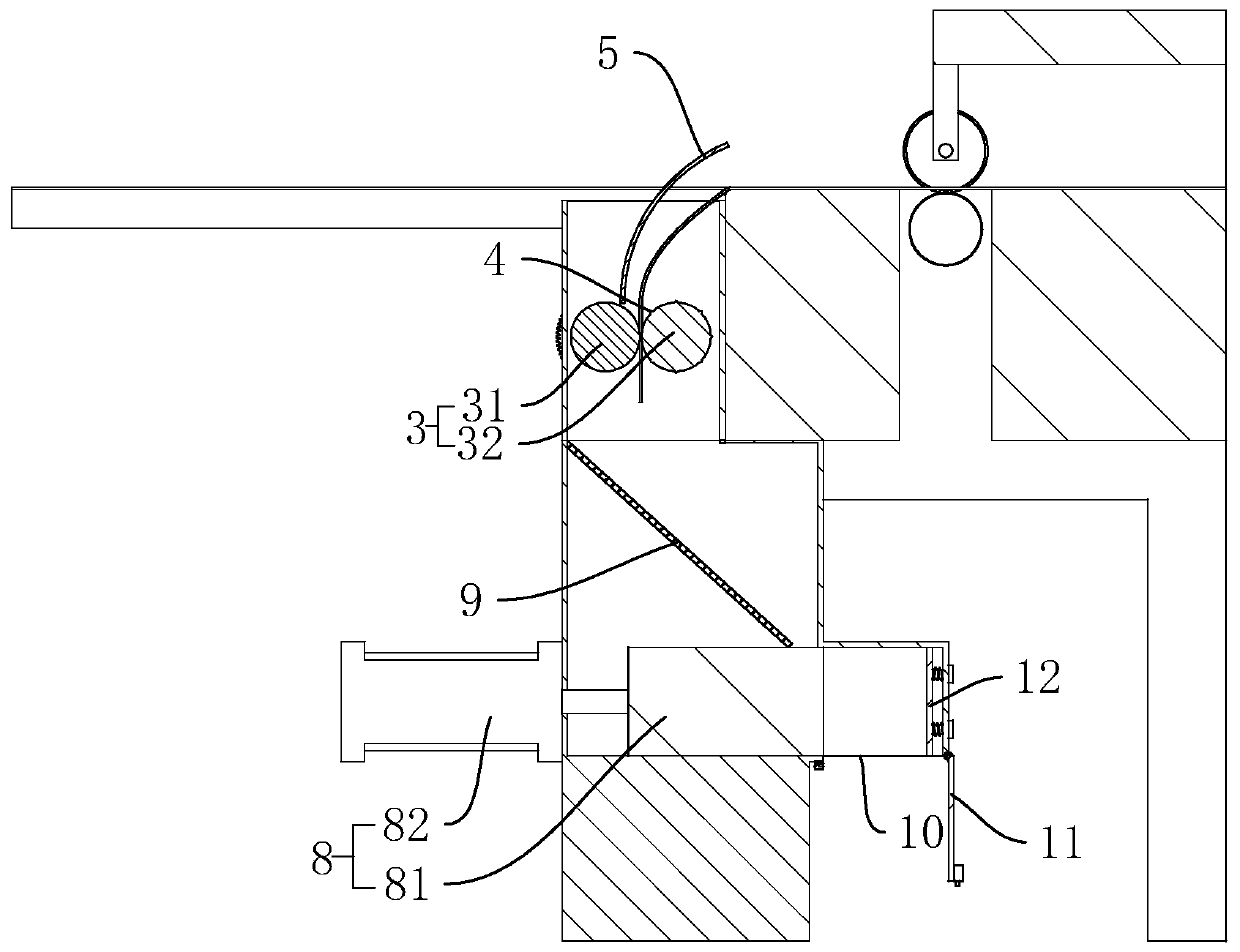

[0036] A waste edge collecting device for corrugated cardboard, such as figure 1 As shown, it is located on the side of the outlet of the cutting machine and is set corresponding to the trimming knife, including the material guide pipe 1 and the recovery box 2 connected to the bottom of the material guide pipe 1 . The feed pipe is vertically arranged, and the feed pipe 1 is arranged as a square tube. The upper opening of the feed pipe 1 is located on the outlet side of the cutting machine and arranged flush with the conveying plane of the cutting machine. The upper opening of the material guide pipe 1 is usually located outside the corrugated cardboard conveying area for waste edges to enter.

[0037] Such as figure 1 , figure 2 As shown, the conveying assembly 3 is provided in the material guiding pipe 1 , and the conveying assembly 3 includes a driving roller 31 rotatably connected in the material guiding pipe 1 , a driven roller 32 and a driving motor 33 arranged on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap